Introduction

A potentiometer is an adjustable resistor component widely used in electronic circuits to regulate current, voltage, and signal distribution. Due to its ability to finely tune circuit parameters, potentiometers are crucial in audio equipment, household appliances, industrial control systems, and precision instruments. This article provides an in-depth exploration of the working principles, classifications, applications, key performance parameters, and selection guidelines of potentiometers in modern electronic engineering.

1. Working Principle and Structure of Potentiometers

A potentiometer typically consists of three terminals: two fixed terminals connected to the power source and load, and a third adjustable terminal known as the wiper (sliding contact). By rotating or sliding the wiper, the resistance changes, thereby adjusting the circuit’s voltage or current.

Key Components and Functionality:

Resistive Element:

Made of materials such as carbon film, metal oxide, or conductive plastic, ensuring stable resistance characteristics.

The length and material of the resistive element determine the maximum resistance range.

Wiper (Sliding Contact):

Connected to an adjustment knob or slider, allowing users to modify the contact point with the resistive element, changing resistance accordingly.

Resistance Variation & Voltage Distribution:

As the wiper moves, the resistance value changes, influencing voltage or current.

A common application of potentiometers is as a voltage divider, where adjusting the wiper modifies the output voltage.

Signal Control:

Besides voltage regulation in DC circuits, potentiometers are also used in AC circuits to control signals, such as adjusting audio volume.

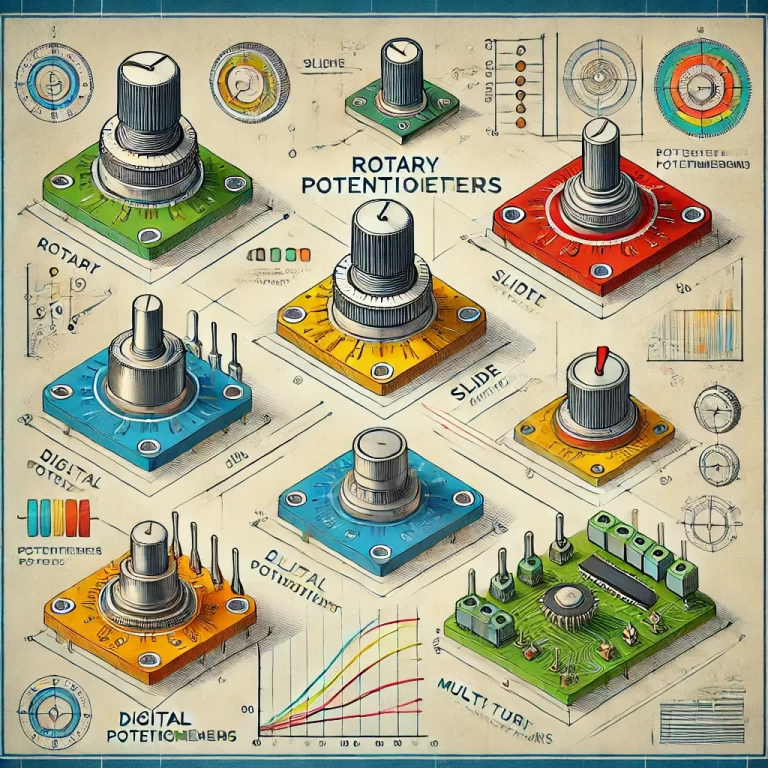

2. Types of Potentiometers and Their Applications

Potentiometers come in various types, each suited for specific applications. Below are the major categories:

1. Rotary Potentiometers

Working Mechanism: Adjusts resistance by rotating a knob.

Applications: Used in audio volume controls, household appliances (brightness adjustment), and other continuous control applications.

Advantages: Simple operation, smooth control, and high durability.

2. Slide Potentiometers

Working Mechanism: Adjusts resistance through a sliding contact.

Applications: Commonly found in laboratory equipment, mixing consoles, and other devices requiring frequent adjustments.

Advantages: Provides fast and precise tuning, suitable for applications requiring quick manual control.

3. Digital Potentiometers

Working Mechanism: Resistance is adjusted using digital signals controlled by microprocessors or digital controllers.

Applications: Ideal for automation, embedded systems, and digital signal processing applications.

Advantages: High precision, remote control capability, and long lifespan due to the absence of mechanical wear.

4. Multi-Turn Potentiometers

Working Mechanism: Utilizes multiple rotation cycles to achieve finer resistance adjustments.

Applications: Used in high-precision instruments, control systems, and high-end audio devices.

Advantages: Offers superior precision compared to standard rotary potentiometers.

| Potentiometer Type | Adjustment Mechanism | Common Applications | Advantages |

|---|---|---|---|

| Rotary Potentiometer | Rotational knob | Audio, appliances | Simple, durable |

| Slide Potentiometer | Linear sliding | Mixing consoles, lab equipment | Quick adjustment |

| Digital Potentiometer | Digital control | Automation, embedded systems | High precision, no mechanical wear |

| Multi-Turn Potentiometer | Multiple rotations | Precision control systems | Extremely fine tuning |

3. Key Performance Parameters and Selection Criteria

When selecting a potentiometer, several performance parameters must be considered based on the application’s specific requirements.

1. Resistance Value Range

Potentiometers have resistance values ranging from a few ohms to several megaohms.

Choosing the appropriate resistance depends on circuit voltage, load, and adjustment requirements.

Incorrect resistance selection may lead to poor performance or circuit failure.

2. Power Rating

The power rating indicates the maximum power the potentiometer can handle without overheating.

Typically ranges from a few hundred milliwatts to several watts.

Selecting a potentiometer with an appropriate power rating prevents overheating and ensures durability.

3. Adjustment Precision and Resolution

High-precision applications (e.g., precision instruments and calibration systems) require fine-tuned potentiometers.

Multi-turn potentiometers provide better precision than single-turn counterparts.

4. Mechanical Lifespan

Indicates the number of adjustment cycles a potentiometer can withstand before failure.

Standard rotary potentiometers have a lifespan of tens of thousands of cycles, whereas digital potentiometers have virtually unlimited lifespan due to the absence of mechanical components.

5. Environmental Stability and Reliability

Potentiometers should maintain performance under various environmental conditions (e.g., temperature, humidity, vibration).

Industrial applications require robust potentiometers with high durability.

4. Advanced Applications of Potentiometers

Potentiometers play crucial roles in various fields. Below are key applications where they are extensively used:

1. Audio Equipment and Home Appliances

Usage: Volume and brightness control in sound systems, TVs, and lighting.

Example: In audio systems, rotary potentiometers adjust volume and sound balance (e.g., bass and treble control).

2. Precision Instrumentation and Measurement

Usage: Used for signal calibration and precision control in measurement devices.

Example: Calibration of sensors in scientific instruments.

3. Industrial Automation and Robotics

Usage: Used for fine-tuning sensor outputs and motor control.

Example: Adjusting motor speed and robotic arm positioning in automated manufacturing.

4. Digital Potentiometers in Embedded Systems

Usage: Used in smart homes, automated control systems, and digital signal processing.

Example: Remote-controlled volume adjustment in smart speakers.

5. Conclusion

Potentiometers serve as vital components in electronic circuits, enabling fine control over resistance, voltage, and signals across a wide range of applications. From simple audio adjustments to complex automation systems, their versatility and reliability make them indispensable in modern electronics. With the advent of digital potentiometers, applications are expanding into more sophisticated control systems, enhancing precision and remote operation capabilities. Understanding potentiometer types, working principles, and selection criteria is crucial for designing efficient and stable electronic devices.

By leveraging potentiometers effectively, engineers and designers can optimize performance and ensure reliability in their electronic projects, making these components indispensable in both traditional and advanced technological applications.