In the world of industrial automation, Programmable Logic Controllers (PLCs) play a vital role in managing real-time operations. One of the most essential yet often overlooked aspects of PLC operation is the scan cycle. Understanding how the PLC scan cycle works can help engineers optimize system performance and ensure reliable, predictable control.

🔄 What Is a PLC Scan Cycle?

A PLC scan cycle refers to the process through which a PLC continuously monitors inputs, executes the control program, updates outputs, and performs background operations. This cycle repeats endlessly during the PLC’s runtime.

Each scan consists of four fundamental stages:

📥 1. Input Scan

During the input scan, the PLC reads the state of all connected input devices—such as sensors, switches, and push buttons—and stores this data in an Input Image Table (IIT). This snapshot of input conditions is used during the logic execution step.

🧠 2. Program Execution

The PLC processes the user-defined logic (typically written in ladder diagram, function block, or structured text) using the stored input values. The results of this logic determine the states of the outputs, which are saved in the Output Image Table (OIT).

⚡ 3. Output Scan

After logic execution, the PLC updates the physical outputs based on the contents of the Output Image Table. This means actuators, relays, solenoids, lights, or motors are energized or de-energized according to the program.

🔧 4. Housekeeping Tasks

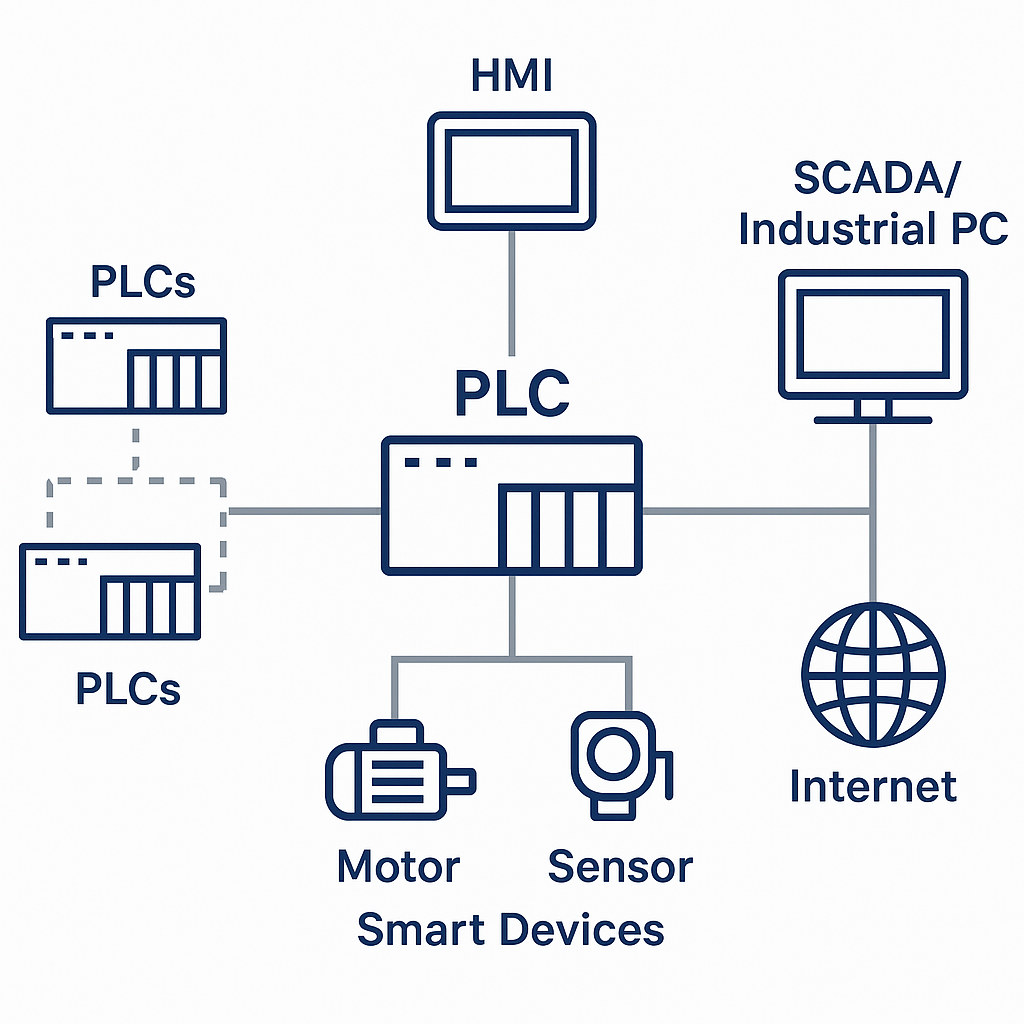

This phase involves internal system diagnostics, communication with HMIs or SCADA systems, updating timers and counters, and managing memory or buffer data. It ensures that the system stays stable and synchronized with other components.

⏱ Typical PLC Scan Cycle Time

The duration of one complete scan cycle depends on several factors, including the complexity of the program, number of I/O points, communication tasks, and hardware performance.

| PLC Type | Typical Scan Time |

|---|---|

| Small PLCs | 1–10 ms |

| Mid-range PLCs | 0.5–5 ms |

| High-performance PLCs | < 1 ms |

| Heavy-load systems | 10–50+ ms |

🛠 Why Scan Cycle Matters

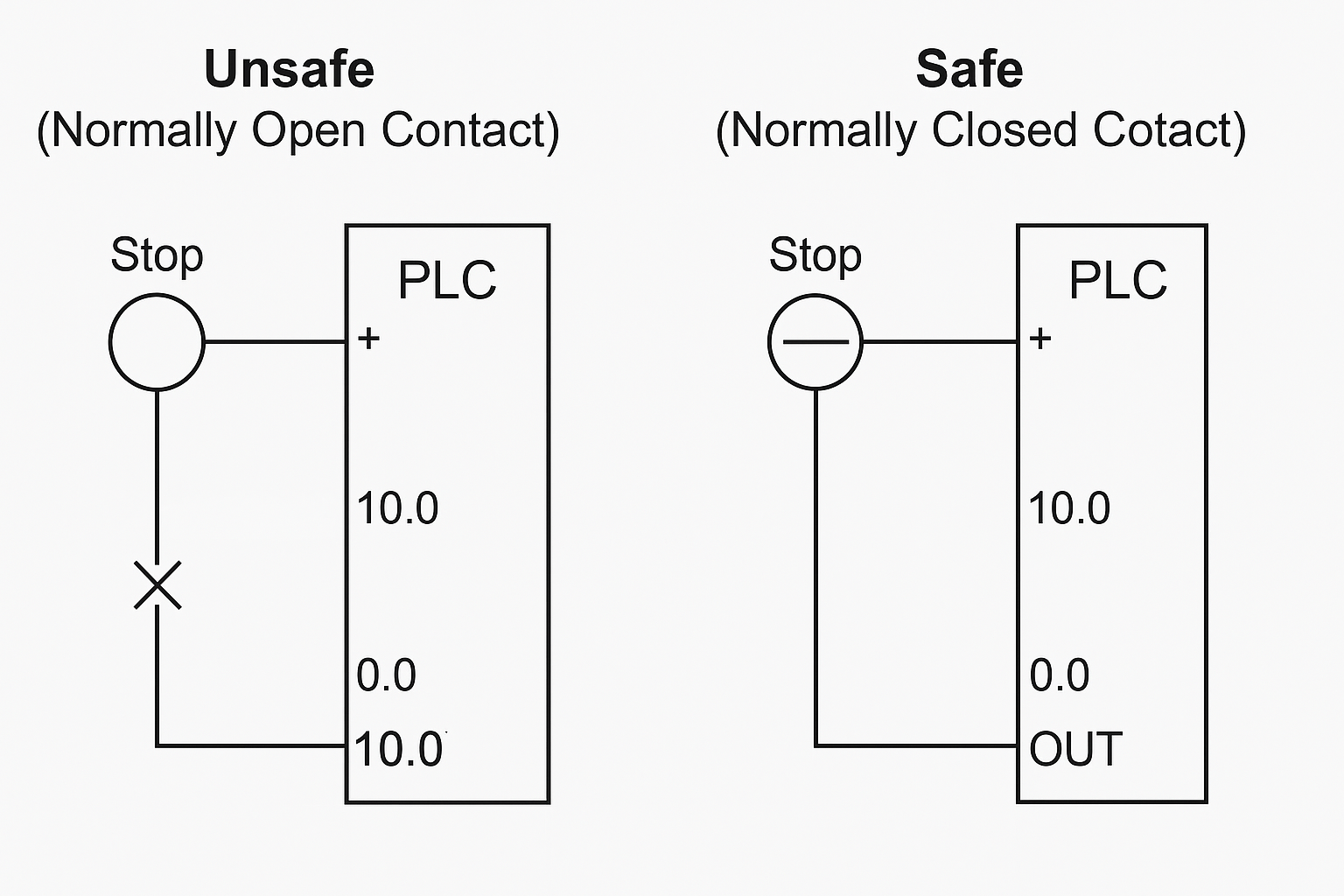

Response Time: If a system demands real-time reaction (e.g., emergency stop), a long scan time could cause unsafe delays.

Precision Control: For applications like servo positioning, packaging, or fast data acquisition, shorter scan times are crucial.

System Optimization: Engineers should monitor and reduce scan cycle time by optimizing ladder logic, avoiding excessive nesting, and minimizing unused I/O or background tasks.

📊 Best Practices to Optimize PLC Scan Cycle

Modularize the program using subroutines or function blocks.

Use high-speed input modules for fast signals.

Minimize unnecessary communication polling.

Monitor scan time using diagnostic tools provided by the PLC software (e.g., Siemens TIA Portal, Mitsubishi GX Works).

🧩 Bonus Tip: Interrupt Routines and Fast Tasks

In time-critical scenarios, many PLCs allow for interrupt routines or fast scan tasks that prioritize certain inputs over regular scanning. These are ideal for high-speed counting, encoder feedback, or safety interlocks.

📌 Conclusion

The PLC scan cycle is the heartbeat of your automation system. Understanding its operation and impact can help you troubleshoot problems, optimize performance, and design more efficient control strategies. Whether you’re working with a simple on/off logic or a complex sequence of operations, managing scan time should always be part of your design checklist.