Programmable Logic Controllers (PLCs) are at the heart of industrial automation, controlling processes from simple on/off operations to complex, multi-axis systems. Understanding how PLCs are classified, their functional tiers, software architecture, memory types, and advanced I/O capabilities is essential for selecting the right solution for your application.

1. PLC Classification by I/O Capacity

PLCs can be grouped based on the number of input/output (I/O) points they support, the processor type, and memory capacity.

| Type | I/O Points | CPU Type | User Program Memory | Key Features |

|---|---|---|---|---|

| Micro PLC | Fewer than 256 points | 8-bit or lower | Less than 16 KB | Compact design, low cost, ideal for simple logic/sequential control |

| Mid-range PLC | 256–1024 points | 8-bit or 16-bit | Less than 32 KB | Enhanced capabilities for medium-complexity automation tasks |

| Large PLC | More than 1024 points | 16-bit or 32-bit | More than 32 KB | High processing power, supports large-scale and complex control systems |

2. PLC Classification by Functional Level

Beyond I/O capacity, PLCs are also categorized by their functional strength.

| Level | Functional Characteristics | Typical Applications |

|---|---|---|

| Low-end PLC | Focused on discrete control, basic logic, timers, counters, shifting, self-diagnostics; limited analog I/O and arithmetic functions; basic communication | Simple machine control, sequential operations, stand-alone equipment |

| Mid-tier PLC | Adds enhanced analog I/O, arithmetic, data handling, device interfaces, networking; may include interrupt handling and PID control | Medium-complexity industrial systems requiring flexible control |

| High-end PLC | Supports advanced math/logic operations, multitasking, multi-program execution, high-speed I/O handling, redundancy, extensive networking and diagnostics | Large-scale, mission-critical automation projects |

3. PLC Software Components

PLC software is divided into two main parts: system software and user programs.

System Software

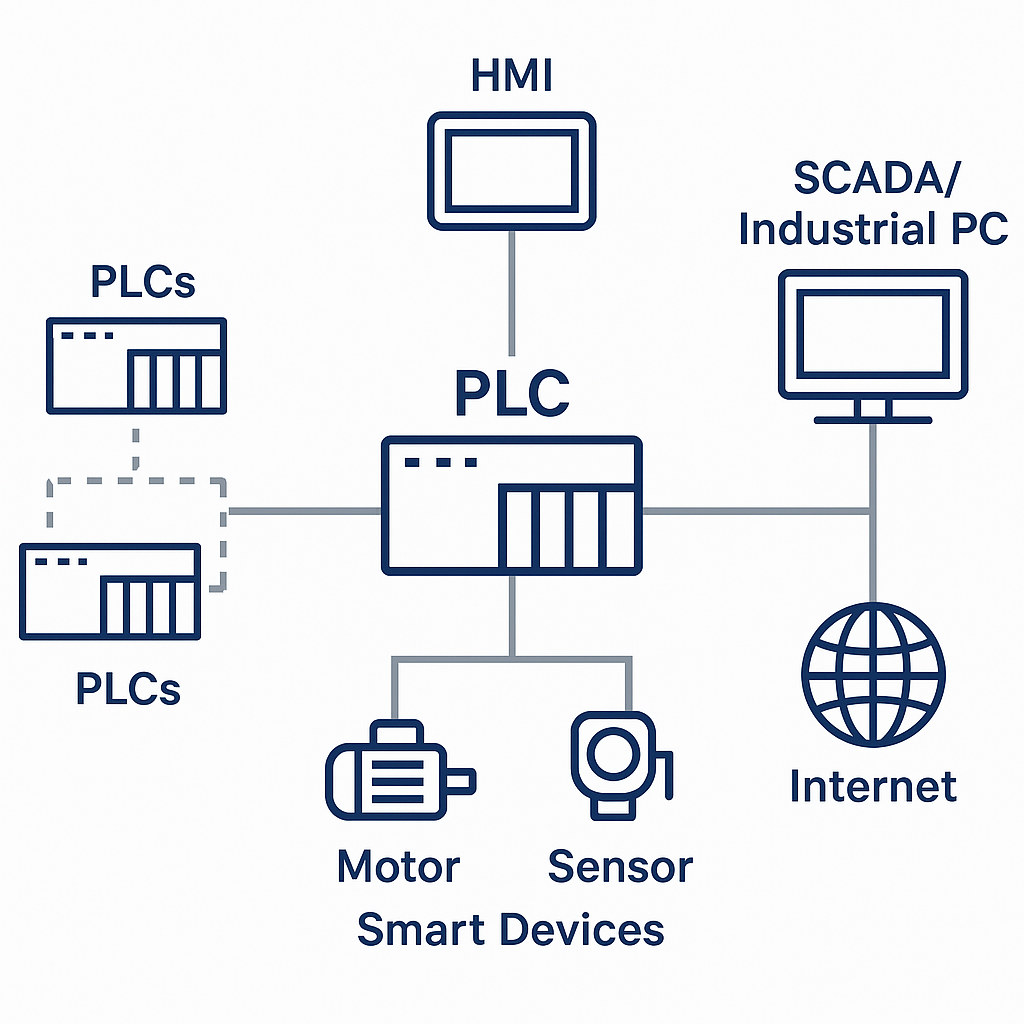

Provided by the manufacturer, stored in non-volatile memory. Includes system firmware, intelligent module firmware, programming/configuration tools, and HMI/SCADA interfaces. Handles tasks like compilation, simulation, diagnostics, and communication management.User Program

Developed by the end-user according to the control requirements, using the PLC’s supported programming languages (ladder diagram, structured text, function block diagrams, etc.). May also include HMI programs (interface layouts, trends, alarms) and communication logic.

4. PLC Memory Types

PLCs use multiple types of memory for different purposes:

RAM (Random Access Memory)

SRAM and DRAM for storing runtime and temporary data.

ROM (Read-Only Memory)

PROM, EPROM, and EEPROM for storing system firmware, application programs, and retained data.

Flash Memory (EEPROM-based)

Includes modern storage media such as TF, CF, MMC, and SD cards, often used for program backup and data logging.

5. Smart I/O Modules

Unlike standard I/O modules, smart I/O units have their own CPU, memory, and interfaces, enabling them to execute specialized tasks independently from the main PLC CPU. They communicate with the PLC via the internal bus.

Common types include:

High-speed pulse counter modules – For counting, accumulation, and speed control of fast pulse inputs.

PID control modules – Execute closed-loop PID control independently, improving control performance and reducing PLC CPU load.

Flow totalizing modules – Perform flow data acquisition, temperature/pressure compensation, batch control, and weighing functions.

Communication interface modules – Convert and bridge various serial or fieldbus protocols; enable remote I/O.

Advanced control modules – Integrate algorithms for speed regulation, multivariable control, and other specialized functions.

Multi-signal modules – Support DI/DO, AI/AO, and configurable I/O via software.

Final Thoughts

Selecting the right PLC involves more than just choosing a brand—it requires matching the controller’s I/O capacity, functional tier, software capabilities, memory options, and smart module support to the demands of your application. Understanding these classifications ensures you can build an automation system that is both cost-effective and future-proof.