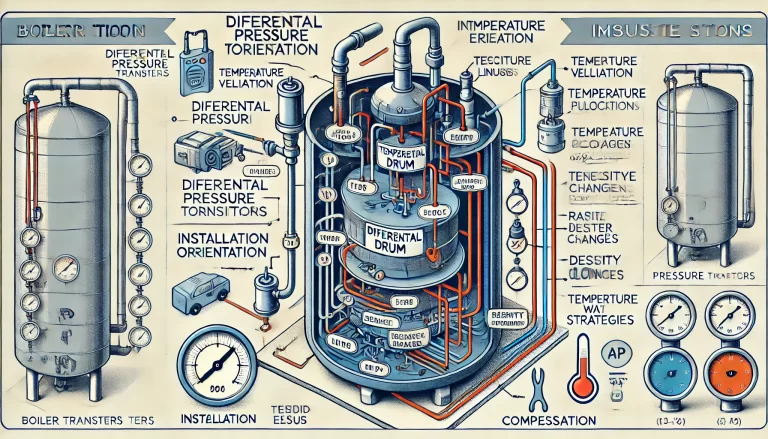

When monitoring and controlling boiler drum water levels, differential pressure (DP) transmitters are commonly employed due to their effectiveness in providing continuous and reliable measurements. However, understanding the potential sources of error in these systems is essential for maintaining accuracy and efficiency in boiler operations. Below, we delve into the primary factors that contribute to measurement errors when using differential pressure water level meters.

1. Temperature Variation

One of the most significant sources of error in DP-based water level measurement is temperature variation. The pressure-sensing lines connecting the boiler drum to the transmitter can be exposed to different temperature conditions. As temperature changes, the density of the fluid in the impulse lines shifts, leading to inaccurate pressure readings and, consequently, erroneous water level measurements.

2. Boiler Pressure Fluctuations

The density of both water and steam inside the boiler varies with changes in pressure. These fluctuations can alter the differential pressure detected by the transmitter, causing a zero-point shift and deviations in water level readings. Effective compensation techniques or specialized transmitter calibrations are necessary to mitigate this type of error.

3. Density Changes in Impulse Lines

The density of the fluid within the high- and low-pressure impulse lines is crucial for accurate measurement. When the density varies due to temperature or pressure changes, the differential pressure reading can be skewed. This is especially prevalent when the temperature distribution is inconsistent along the length of the impulse lines.

4. Installation Position and Orientation

The physical installation of the differential pressure transmitter plays a vital role in measurement accuracy. If the transmitter or the impulse lines are not installed correctly, such as being non-horizontal or improperly aligned, gravitational effects can introduce additional measurement errors. Proper installation procedures and regular checks can reduce these risks.

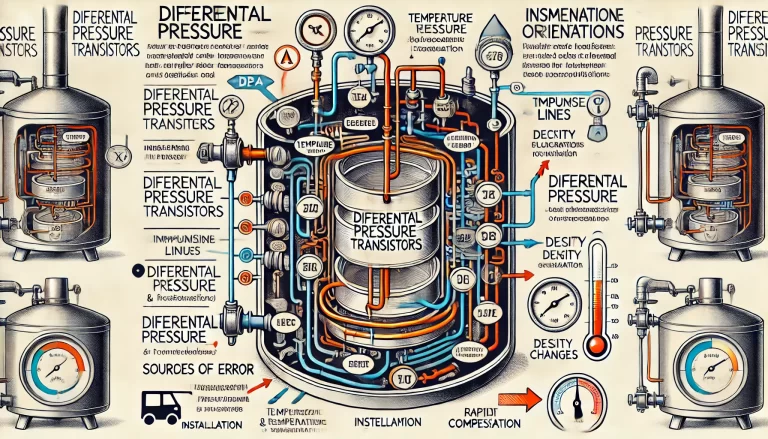

5. Leakage and Blockage in Impulse Lines

Leaks or blockages in the impulse lines are common issues that lead to incorrect pressure readings. A blockage, for instance, prevents accurate transmission of the pressure to the transmitter, causing discrepancies in the detected water level. Regular maintenance and inspection of these lines are essential for ensuring reliable operation.

6. Condensate Level Changes

In systems equipped with condensate pots or seal pots, changes in the condensate level can impact the zero-point of the differential pressure transmitter. If the level of the condensate varies due to temperature changes or system dynamics, this can result in significant measurement drift. Ensuring a stable condensate level through proper design and maintenance practices can mitigate this issue.

7. Dynamic Effects of Fluid Movement

Rapid or turbulent changes in the boiler’s water level can introduce dynamic errors. Such fluctuations cause the pressure readings to oscillate, leading to unstable and inaccurate measurements. This can be particularly problematic in systems that experience frequent load changes or disturbances.

Mitigation Strategies

To minimize these potential sources of error, several strategies can be employed:

Temperature Compensation: Implementing temperature compensation techniques can help adjust for changes in fluid density along the impulse lines.

Pressure Compensation: Using pressure-compensated DP transmitters ensures more accurate readings when the boiler pressure varies.

Regular Maintenance: Periodic checks and maintenance of impulse lines can prevent leakage or blockages.

Proper Installation: Ensuring that the transmitter and associated equipment are correctly installed and aligned helps maintain measurement accuracy.

Advanced Transmitter Features: Using transmitters with smart diagnostics and automated compensation for environmental factors can improve the reliability of measurements.

Understanding these factors and adopting appropriate mitigation measures is crucial for achieving accurate water level monitoring in boiler systems, ensuring operational safety and efficiency.