Introduction

When you apply and remove a load from a weighing system, you’d expect the sensor to return the exact same output, right?

But in reality, it often doesn’t.

That difference in sensor output between loading and unloading is called hysteresis—and it’s one of the key error sources in load cell performance.

This article explores what load cell hysteresis is, what causes it, and how to reduce its impact in your weighing applications.

1. What Is Hysteresis in Load Cells?

Hysteresis is the difference in output from a load cell at a given load point, depending on whether the load is increasing or decreasing.

❝ If you load 100 kg and get 2.000 V, and unload back to 100 kg but get 1.998 V—that’s hysteresis. ❞

It creates a lag or “memory” effect in the sensor’s behavior.

2. How Is Hysteresis Specified?

Manufacturers specify hysteresis as:

±0.03% of Full Scale (F.S.)

→ This means output variation at the same load point will not exceed ±0.03% of the full rated capacity.

It’s typically tested under slow, controlled cycles in a lab.

3. What Causes Hysteresis?

Several mechanical and material factors contribute to hysteresis:

🔩 Elastic deformation lag: The sensor structure doesn’t return perfectly

🔧 Friction within mechanical joints or mountings

🧵 Strain gauge adhesive behavior under stress

🧊 Material microplasticity or micro-slippage

🔄 Residual stress from manufacturing or welding

🌡️ Temperature variation can worsen hysteresis behavior

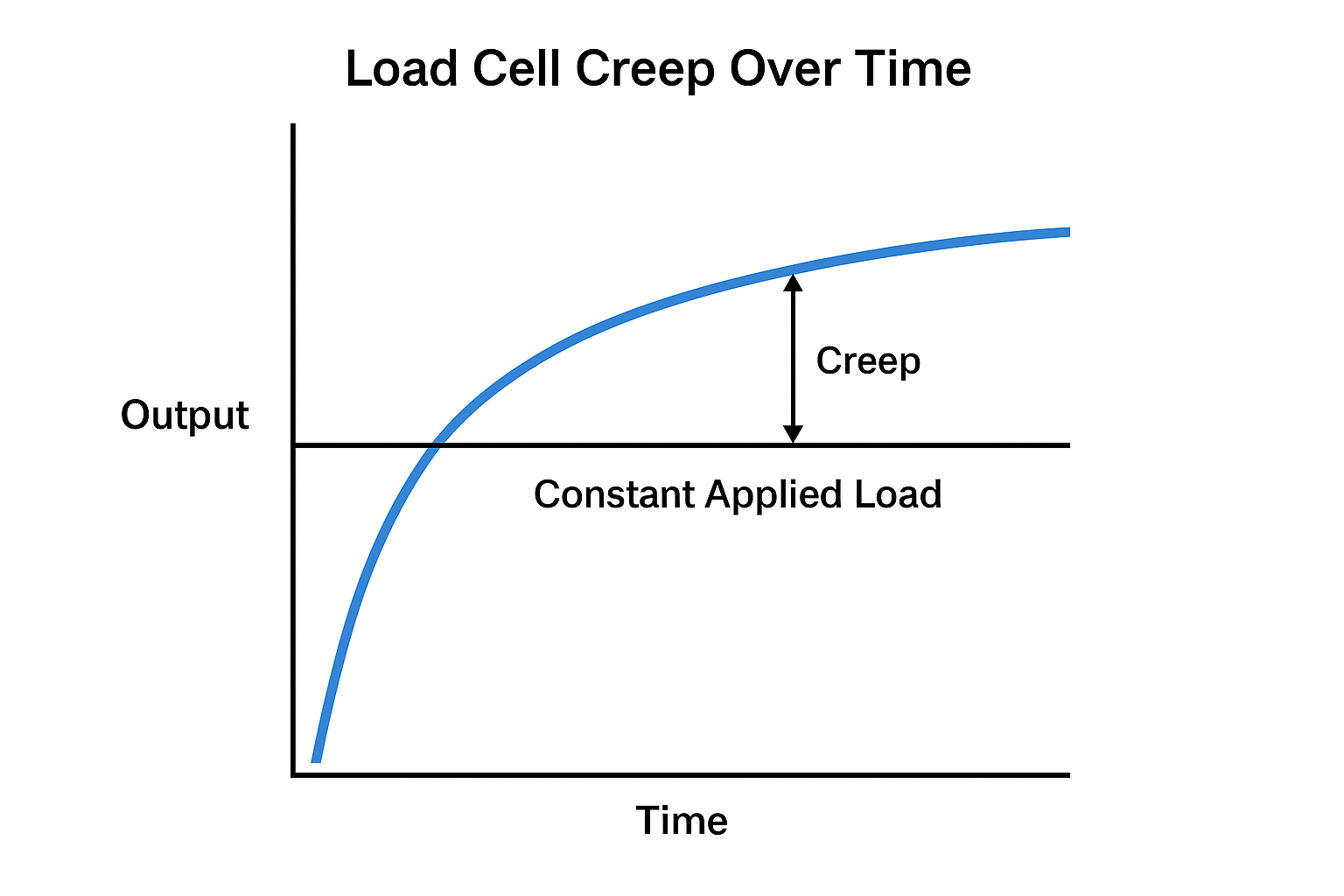

4. Hysteresis vs Creep vs Non-Linearity

| Error Type | Description |

|---|---|

| Hysteresis | Difference between loading and unloading output |

| Creep | Drift over time under constant load |

| Non-linearity | Output not forming a straight line across range |

Hysteresis is directional, whereas creep is time-based.

5. Why Does Hysteresis Matter?

Hysteresis can:

Reduce repeatability of measurements

Lead to inaccurate readings in systems with variable loading

Cause process control errors in batch operations

Affect compliance with trade/legal-for-sale standards

In high-precision environments, even a ±0.02% F.S. hysteresis can translate to significant weight deviation.

6. How to Minimize Hysteresis

✅ Choose Low-Hysteresis Load Cells

Look for specs below ±0.02% F.S., especially in precision tasks

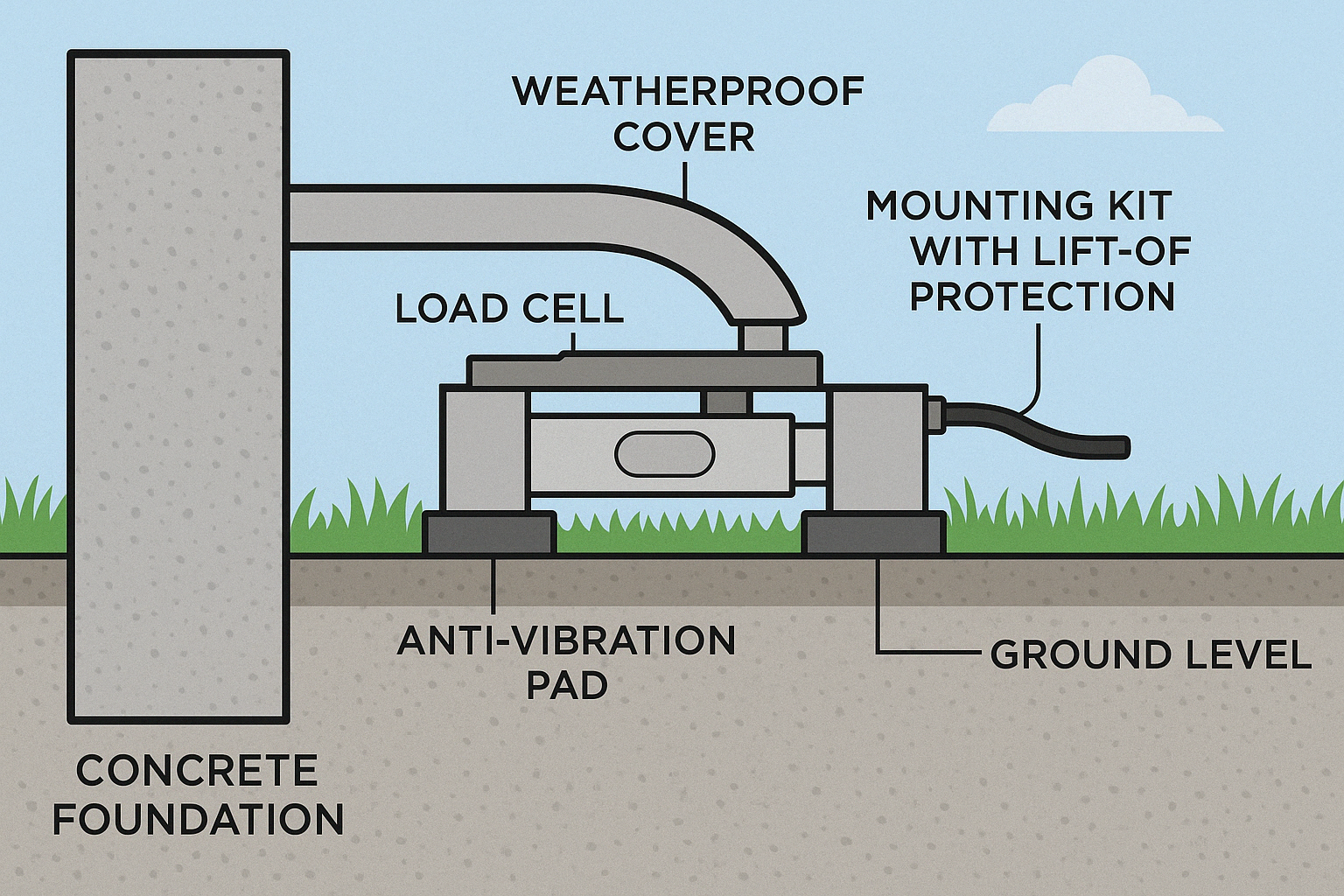

✅ Avoid Mechanical Slack

Mounting hardware and structures should be tight and aligned

✅ Install in a Controlled Temperature Environment

Thermal gradients can exaggerate hysteresis effects

✅ Use Preloaded Mounts or Anti-Friction Bearings

To reduce backlash and movement hysteresis

✅ Allow Load Cells to Settle Before Reading

Avoid capturing values immediately during fast unloading

7. Is Hysteresis Reversible?

Yes—hysteresis is typically elastic and reversible.

However, repeated overload or fatigue can create permanent deformation or residual error.

In such cases, recalibration or replacement is required.

Conclusion

Hysteresis is a fundamental characteristic of all strain-based load cells—but its magnitude can vary widely depending on design, materials, and mounting.

By understanding what causes hysteresis and how to limit its impact, you can build more stable, reliable, and repeatable weighing systems—especially in dynamic or bidirectional loading applications.

When accuracy matters, hysteresis is not just a detail—it’s a design consideration.