Introduction

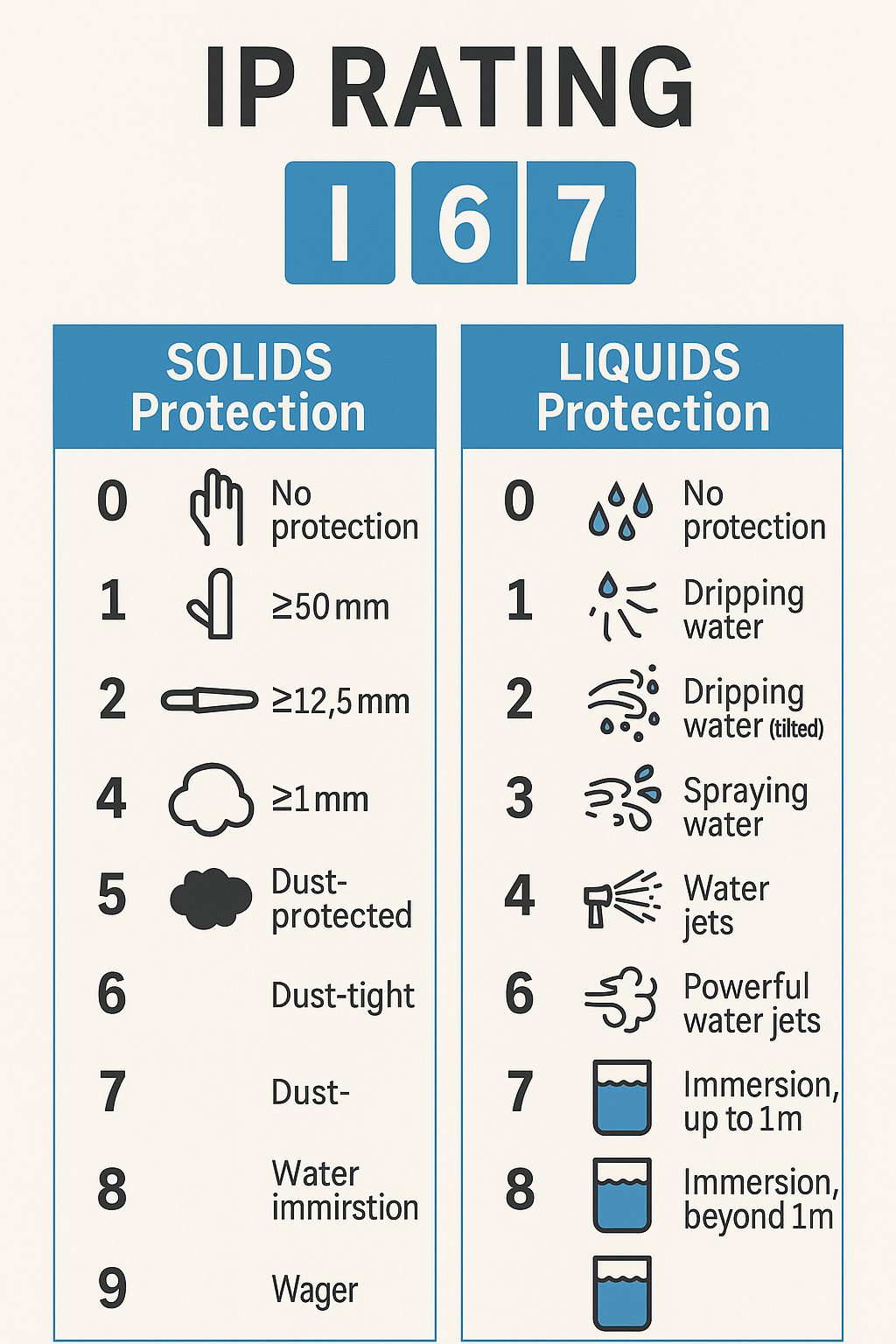

When selecting sensors for industrial or outdoor applications, you’ve likely seen ratings like IP65, IP67, or IP68 on datasheets. But what do these numbers actually mean?

IP ratings—short for Ingress Protection—tell you how well a sensor is protected against dust and water. Selecting the right IP rating ensures your equipment survives in its working environment.

In this article, we break down how IP ratings work, what IP67 specifically means, and how to choose the right protection level for your application.

1. What Is an IP Rating?

An IP (Ingress Protection) rating is a standardized system defined by IEC 60529, used to classify the degree of protection provided by enclosures of electrical devices.

It consists of two digits:

IP X Y

X = protection against solid particles (e.g., dust)

Y = protection against liquids (e.g., water)

2. IP Rating Breakdown Table

| Rating | Solids Protection (1st Digit) | Liquids Protection (2nd Digit) |

|---|---|---|

| 0 | No protection | No protection |

| 1–2 | Large particles (≥50 mm) | Dripping water (vertical or tilted) |

| 3–4 | Tools, wires, small particles | Sprays and splashes |

| 5 | Dust protected (not 100% tight) | Low-pressure water jets |

| 6 | Fully dust-tight | High-pressure water jets (IP66) |

| 7 | – | Immersion up to 1m for 30 minutes (IP67) |

| 8 | – | Immersion beyond 1m, under conditions |

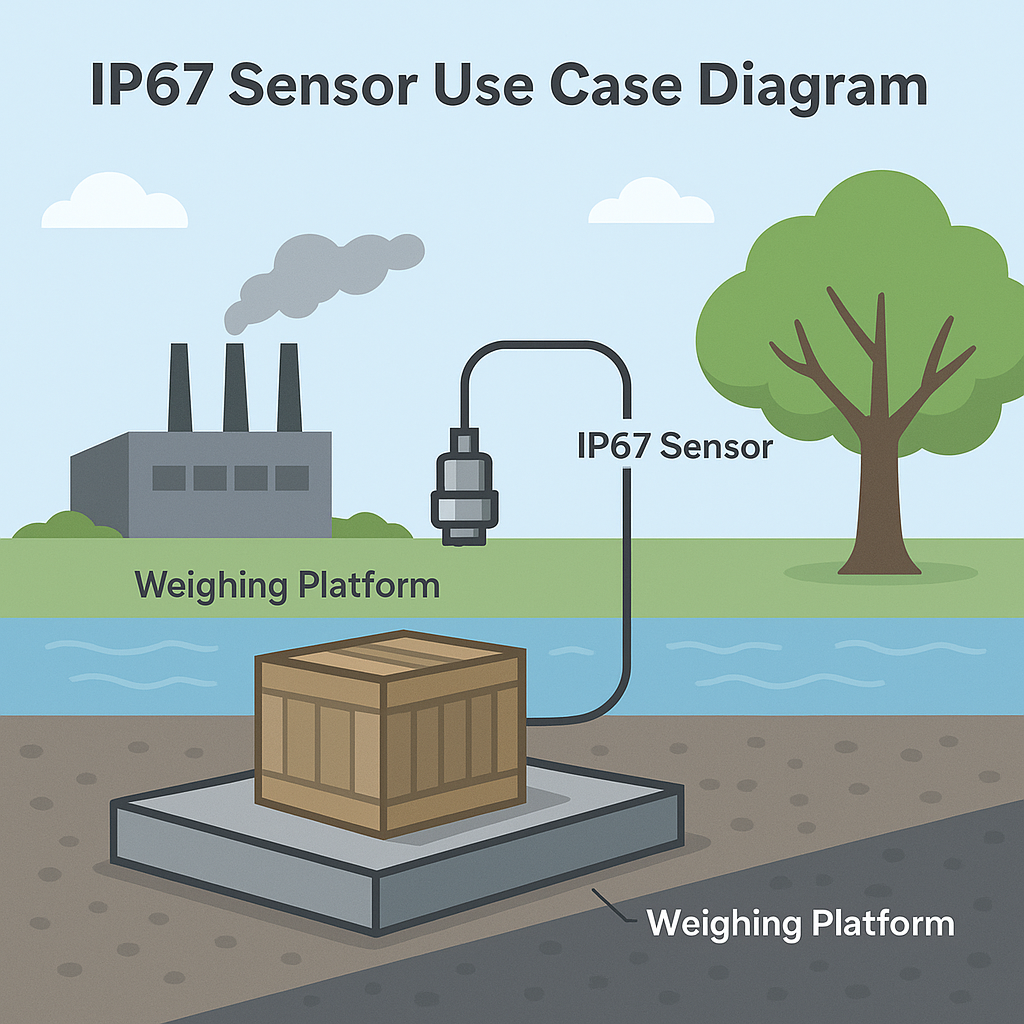

3. What Does IP67 Mean Specifically?

✅ IP67 = Dust-tight + Water immersion resistant

6: Total protection against dust; no ingress at all

7: Can withstand immersion in water up to 1 meter for 30 minutes

This makes IP67 sensors suitable for:

Outdoor systems exposed to rain or mud

Washdown areas in food or pharma factories

Temporary submersion (e.g., flooded pits or basins)

Industrial automation where water spray is common

4. When Should You Choose Higher IP Ratings?

| Use Case | Recommended IP Rating |

|---|---|

| Indoor factory floor (dry) | IP54 – IP65 |

| Light washdown or dust exposure | IP65 – IP66 |

| Outdoor environments / rain | IP66 – IP67 |

| Short-term submersion risk | IP67 |

| Continuous underwater use | IP68 (custom qualified) |

| Hazardous/explosive zones | IP65+ + Ex-proof rating (e.g., ATEX) |

Note: IP67 doesn’t mean “waterproof forever”—just temporary, shallow submersion under lab conditions.

5. Tips for Ensuring Real-World Protection

Use sealed connectors and cable glands with the same IP rating

Avoid breaking seals with improper installation (e.g., overtightening)

For harsh environments, add secondary enclosures

Remember: the entire system must be IP-rated—not just the sensor housing

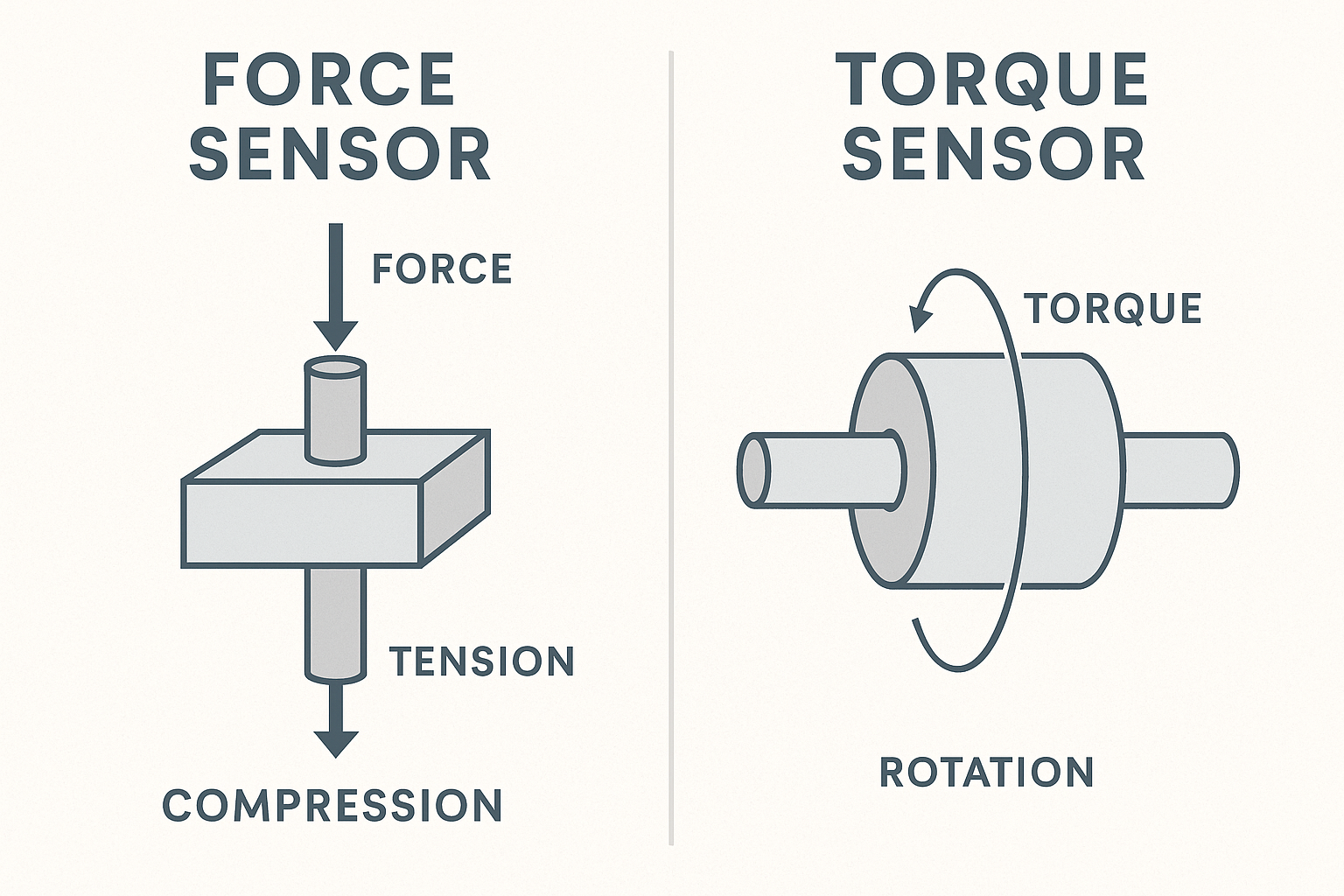

6. Beyond IP: What IP Ratings Don’t Cover

IP ratings do not guarantee:

Corrosion resistance (e.g., salt spray or chemicals)

Shock or vibration protection

UV or sunlight aging

Hygiene standards (e.g., FDA-compliant design)

For extreme conditions, look for:

NEMA ratings (U.S. equivalent)

ATEX / IECEx for explosive atmospheres

IP69K for high-pressure, high-temp washdowns

Conclusion

IP ratings are more than just numbers—they’re essential for ensuring your sensors survive and perform reliably in challenging environments.

For most industrial and outdoor applications, IP67 offers excellent protection against dust and water. But don’t stop there—understanding the limits of IP ratings helps you choose smarter and design more robust systems.

Right IP = Longer sensor life + fewer headaches.