In industrial automation and safety systems, instrument fault safety (also known as fail-safe design) is a crucial principle. It ensures that in the event of a failure—whether in sensors, controllers, or actuators—the process transitions to the safest possible state, preventing accidents, equipment damage, or environmental harm.

🔍 1. What Is Instrument Fault Safety?

Instrument fault safety refers to the system’s inherent ability to remain safe or move to a predefined safe state when one or more of its components fail. This includes:

Sensor signal loss or distortion

Control logic error

Actuator power or air failure

Communication failure

A fail-safe condition does not mean the system keeps working as intended—it means that even in failure, it avoids making the situation worse.

⚙️ 2. Examples of Fail-Safe Design

📌 2.1 Control Valve Fail-Safe Actions

When a control valve loses power or signal, it should default to a position that minimizes risk. The three most common fail-safe actions are:

| Fail-Safe Action | Description | Typical Application |

|---|---|---|

| Fail Close (FC) | Valve closes when power/air fails | Flammable or toxic media |

| Fail Open (FO) | Valve opens upon failure | Cooling water, relief bypass |

| Fail Last (FL) | Valve holds its last position | Critical continuous processes |

✅ Example: In cooling systems, a valve is often set to Fail Open to ensure coolant continues to flow even during a power outage.

📌 2.2 Transmitter Signal Failure Handling

Transmitter faults (e.g., open loop, sensor failure) must trigger logical safety responses:

Dead signal detection (e.g., 3.6mA or 21.8mA in 4-20mA loops)

Voting logic (e.g., 2oo3 logic for redundant sensors)

Fail-high or fail-low configuration, depending on process risk

🛠 For a tank high-level alarm, a sensor fault may be treated as high level to trigger emergency shutoff.

🔒 3. Relation to SIL and SIS

SIL (Safety Integrity Level) is a measure of risk reduction provided by a Safety Instrumented Function (SIF).

SIS (Safety Instrumented System) is designed specifically to handle critical fault-safe functions (shutdowns, isolation, alarms).

The higher the SIL, the more robust the fault-detection, diagnostics, and fail-safe mechanisms must be.

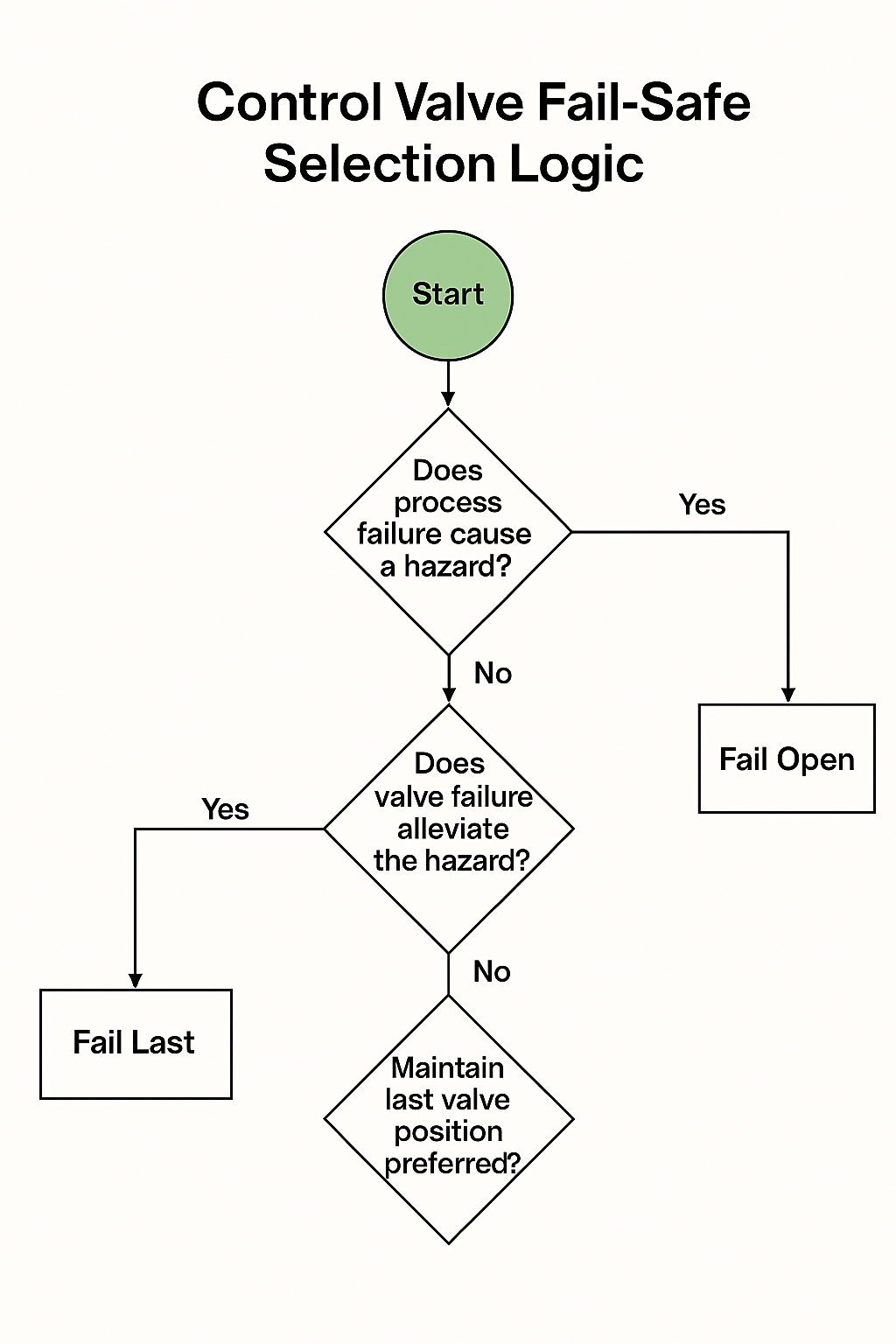

📐 4. Fail-Safe Action Selection Logic

Here is a logic diagram to help determine appropriate fail-safe actions for valves in various process conditions:

🖼️ Illustration: Control Valve Fail-Safe Selection Logic

📘 Conclusion

Designing fault-safe instrumentation is a proactive safety strategy that protects not only the facility but also lives and the environment. It requires a deep understanding of process behavior, failure modes, and the correct default actions for all field devices.

If you’d like a custom infographic PDF, a PowerPoint training slide, or integration into your website, let me know — I can prepare them accordingly.