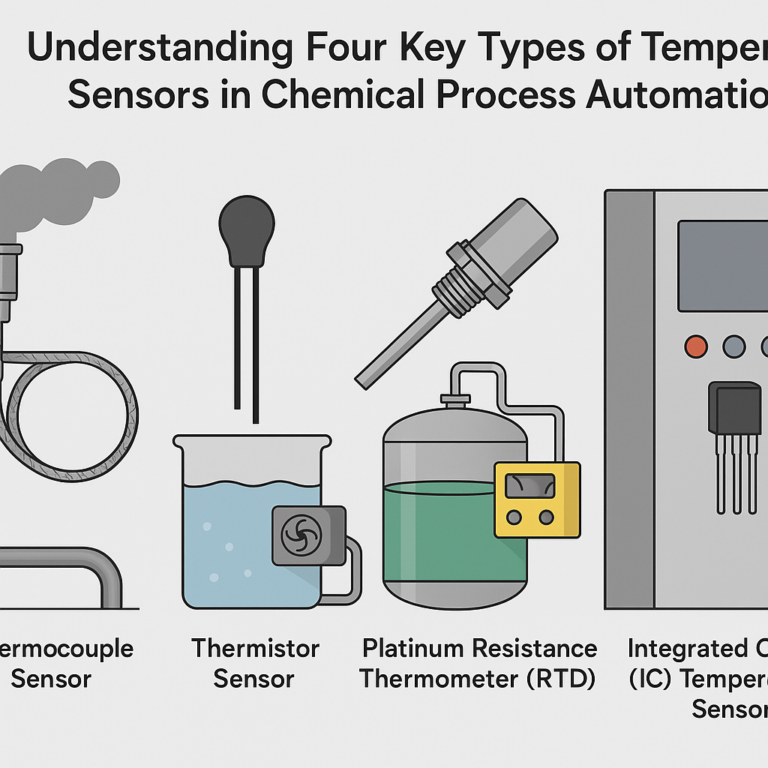

Temperature sensors are fundamental components in industrial instrumentation systems, especially in chemical plants where process control and safety heavily rely on precise temperature monitoring. These sensors convert thermal energy into electrical signals using various physical principles and are widely classified based on their construction, sensing material, and measurement method.

This article explores four commonly used temperature sensors in industrial automation—thermocouples, thermistors, RTDs (resistance temperature detectors), and integrated (IC) temperature sensors—highlighting their principles, characteristics, and typical application scenarios in chemical enterprises.

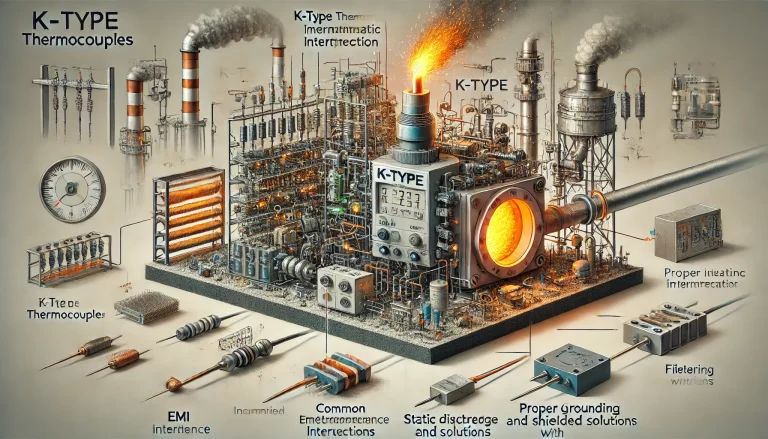

1. Thermocouple Sensors

Working Principle:

Thermocouples operate based on the Seebeck effect: when two dissimilar metals are joined at one end and exposed to a temperature gradient, a voltage (thermoelectric EMF) is generated, which can be correlated to temperature.

Advantages:

Self-powered (no external excitation required)

Wide temperature range (can measure up to 1800°C depending on type)

Cost-effective and robust

Adaptable to harsh environments including corrosive gases and extreme heat

Limitations:

Lower measurement accuracy and stability compared to RTDs

Requires cold junction compensation for accurate readings

Common Types:

K-type: General-purpose, up to ~1250°C

J-type, T-type, S-type, E-type, N-type: Vary in material, range, and stability

Typical Applications in Chemical Plants:

Monitoring exhaust gas temperature in furnaces

Reactors and combustion chamber temperature control

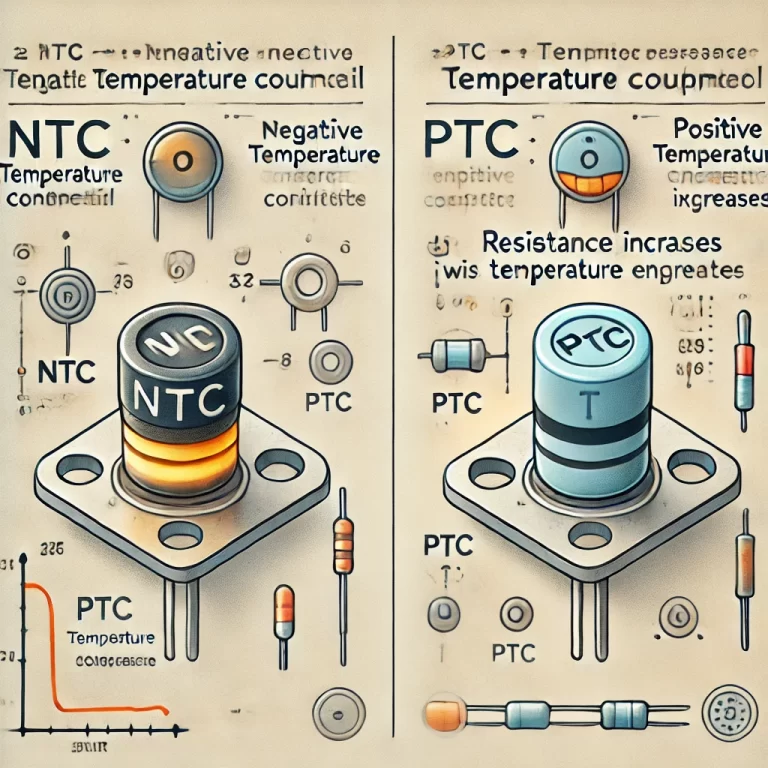

2. Thermistor Sensors (NTC/PTC)

Working Principle:

Thermistors are temperature-sensitive resistors whose resistance changes significantly with temperature.

NTC (Negative Temperature Coefficient): Resistance decreases with rising temperature

PTC (Positive Temperature Coefficient): Resistance increases with rising temperature

Advantages:

High sensitivity in narrow temperature ranges

Low cost and easy to integrate

Fast response time

Limitations:

Limited temperature range (typically –90°C to 130°C)

Non-linear response, requiring calibration or linearization

Typical Applications:

Overheat protection in control cabinets

Monitoring coolant system temperatures

Localized temperature sensing in small-scale processes

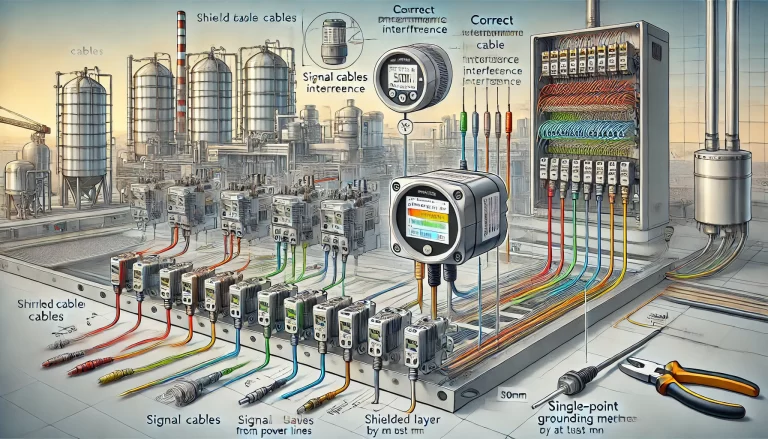

3. Platinum Resistance Thermometers (RTDs: PT100, PT1000)

Working Principle:

RTDs are metallic resistors—commonly made of platinum—whose resistance increases linearly with temperature. They offer highly accurate and stable temperature readings.

Advantages:

Excellent accuracy and repeatability

Good long-term stability

Wide operating range (–200°C to 600°C)

Good vibration resistance

Limitations:

More expensive than thermocouples or thermistors

Requires external excitation current

Sensitive to wiring resistance (especially in 2-wire setups)

Common Types:

PT100: 100Ω at 0°C

PT1000: 1000Ω at 0°C (higher sensitivity)

Typical Applications:

Reactor vessel jacket temperature monitoring

Control of heat exchangers and distillation columns

Laboratory calibration equipment

4. Integrated Circuit (IC) Temperature Sensors

Working Principle:

IC temperature sensors are silicon-based devices that integrate sensing and signal conditioning in a single chip, providing either analog or digital output.

Advantages:

Compact and lightweight

Low power consumption

Digital or analog signal output

High accuracy in low-to-moderate temperature ranges

No need for complex signal conditioning

Limitations:

Limited operating temperature range (typically –55°C to 150°C)

Lower robustness compared to industrial-grade sensors

Common Models:

LM35: Analog output

DS18B20: Digital output via 1-Wire protocol

Typical Applications:

Ambient temperature monitoring inside control panels

Remote sensor nodes in distributed systems

Embedded systems and microcontroller-based automation

Comparison Table of Key Characteristics

| Sensor Type | Temperature Range | Accuracy | Response Time | Cost | Robustness | Typical Use Case |

|---|---|---|---|---|---|---|

| Thermocouple | –200°C to 1800°C | Moderate | Fast | Low | High | Furnace, Flue Gas Monitoring |

| Thermistor | –90°C to 130°C | High (in range) | Very Fast | Low | Moderate | Cabinet/Water Temperature Monitoring |

| RTD (PT100/1000) | –200°C to 600°C | Very High | Moderate | Medium | High | Process Control, Lab Measurement |

| IC Sensor | –55°C to 150°C | High | Fast | Low | Low | Control Panel Monitoring, Microcontroller |

Conclusion

Choosing the right temperature sensor in a chemical plant depends on the specific temperature range, accuracy, installation environment, and cost constraints. Understanding the strengths and limitations of each sensor type is essential for process engineers, instrumentation specialists, and maintenance teams aiming to optimize both performance and safety.

If you’re selecting a temperature sensor for your application and need further guidance, feel free to reach out to our engineering team at Dalian Zero Instrument Technology Co., LTD for customized solutions.