Introduction

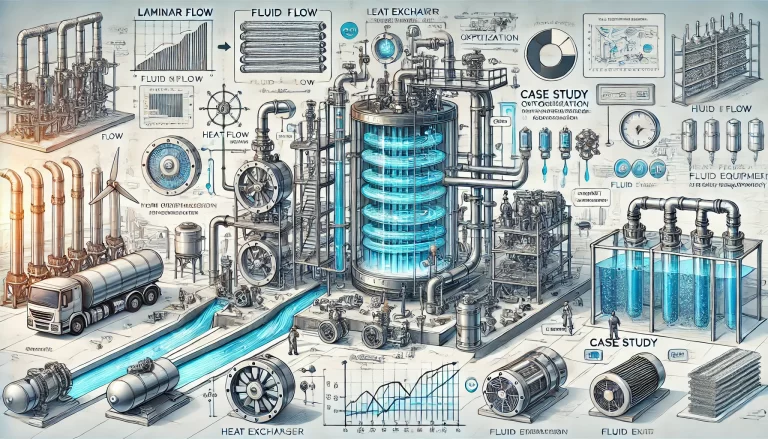

Fluid equipment plays a crucial role in modern industrial systems, with applications across sectors such as petrochemicals, power generation, metallurgy, environmental engineering, food processing, and pharmaceuticals. These systems are involved in the transportation, treatment, distribution, mixing, heat exchange, and control of fluids, encompassing a range of mechanical, thermodynamic, and chemical processes.

1. Physical Principles in Fluid Equipment

Design and operation of fluid equipment cannot be divorced from fundamental physical principles such as fluid dynamics and thermodynamics. This section explores these principles, focusing on fluid flow characteristics, energy transformation, pressure losses, and heat exchange.

Flow Dynamics and Fluid Mechanics

Fluid mechanics, which studies the motion of fluids under the influence of forces, is extensively applied in designing fluid equipment. Understanding the flow state and resistance is crucial for designing systems that minimize friction losses and optimize energy use.

Flow Types:

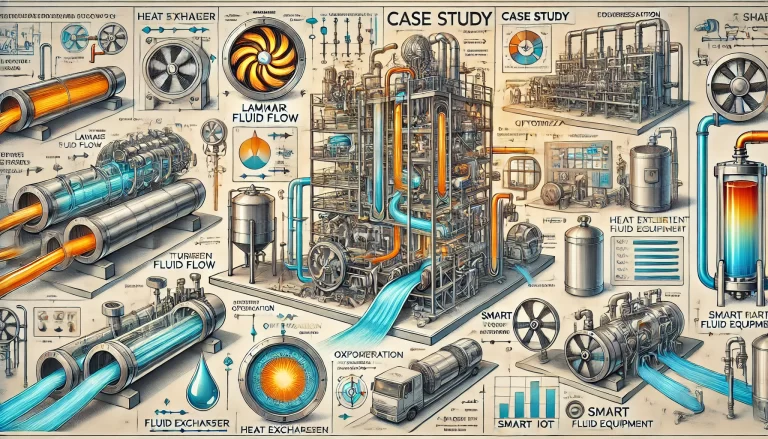

Laminar Flow occurs at lower velocities with layers of fluid moving parallel to each other, resulting in minimal friction.

Turbulent Flow occurs at higher velocities where fluid movements become irregular, increasing friction losses.

Pressure Loss and Energy Transfer: Effective design reduces energy consumption by minimizing pressure losses, which occur due to friction and localized losses in components like pipes, pumps, and valves.

Reynolds Number and Flow Transition: The Reynolds number, a dimensionless quantity, determines whether the flow is laminar or turbulent. Fluid equipment design often aims to optimize this number to reduce energy loss and enhance operational stability.

Heat Transfer Principles

Heat exchange is a key function in devices like heat exchangers and cooling towers. Factors such as thermal conductivity, flow velocity, and temperature gradients significantly affect heat exchange efficiency.

2. Case Study: Optimizing Heat Exchangers

To illustrate practical applications, consider a case study of a heat exchanger used in a chemical processing plant. By increasing the heat transfer area and enhancing the turbulence of the fluid, the heat exchanger’s efficiency was improved by 20%. This optimization involved using computational fluid dynamics (CFD) to simulate different flow configurations.

3. Chemical Principles in Fluid Equipment

Besides physical processes, chemical principles play a vital role in devices designed for chemical reactions, gas-liquid separation, and corrosion control.

Corrosion and Its Management Corrosion, often caused by chemical interactions within fluids, can significantly degrade equipment. Using corrosion-resistant materials like stainless steel and applying protective coatings are common mitigation strategies.

Chemical Reactions and Material Transfer Optimizing conditions to control reaction rates and enhance material transfer efficiency is crucial in equipment like reactors and separators.

4. Fluid Equipment Types and Applications

Transportation Equipment: Pumps, fans, and compressors are used to move fluids from one location to another, each designed for specific fluid types and pressure requirements.

Heat Exchange Devices: These are vital in industrial processes, transferring heat between fluids to regulate system temperatures.

Separation Equipment: Devices like separators and filters are used to isolate different components of fluid mixtures.

5. Future Trends: Sustainability and Smart Systems

As environmental regulations become stricter, the design of fluid equipment increasingly focuses on reducing environmental impact and enhancing energy efficiency. The integration of IoT and AI technologies enables real-time monitoring and automated control, improving reliability and operational efficiency.

Conclusion

By deepening the understanding of fluid dynamics and chemistry, and considering real-world complexities, the design of fluid equipment can be optimized for better efficiency and reliability. This promotes a move towards more sustainable, efficient, and intelligent industrial practices.