Have you ever noticed the numbers on the top of a bolt—like 8.8, 10.9, or 12.9? These are not just random figures; they represent the strength grade of the bolt, and they hold the key to ensuring safety and reliability in various structures, from bridges to wind towers to industrial buildings, and even in your car.

What Do the Numbers on the Top of a Bolt Represent?

The numbers, such as 8.8, 10.9, and 12.9, are not arbitrary labels but rather indicate the bolt’s strength grade according to the international standard ISO 898-1. These figures serve as a “health report” for the bolt, providing information about its tensile strength and yield strength.

The first number indicates the tensile strength (how much force the bolt can withstand before breaking).

The second number represents the yield strength ratio, which tells you when the bolt will begin to deform permanently.

These two factors are essential in determining whether the bolt can withstand forces, remain intact without permanent deformation, and prevent loosening during use in real-world applications.

The Mechanics Behind the Numbers

Let’s break down the meaning of a grade 8.8 bolt, one of the most common types:

The first “8” represents the tensile strength, calculated as 8 × 100 = 800 MPa. This means the bolt can withstand a force of 800 Newtons per square millimeter, equivalent to about 80 kilograms of weight.

For instance, a M20 8.8 bolt (with an effective cross-sectional area of 245 mm²) can withstand a tensile force of 800 MPa × 245 mm² = 196,000 N, or about 20 tons.

A grade 4.8 bolt only has a tensile strength of 400 MPa, roughly half of what the grade 8.8 bolt can handle.

The second “8” represents the yield strength ratio, which is 0.8. Therefore, the yield strength (the point at which the bolt starts to deform permanently) is 800 × 0.8 = 640 MPa. The bolt will break when the stress reaches 800 MPa, but it begins to deform at 640 MPa. This gives the bolt a “plastic buffer zone” that prevents sudden failure and provides a warning before breakage.

The Three Main High-Strength Bolt Grades

Grade 8.8:

Tensile Strength: ≥ 800 MPa

Yield Strength: ≥ 640 MPa

Materials: 45# steel, 35CrMo

Applications: Structural steel, factory connections

Characteristics: Balanced performance, high cost-effectiveness

Grade 10.9:

Tensile Strength: ≥ 1000 MPa

Yield Strength: ≥ 900 MPa

Materials: 42CrMo, 35CrMoV

Applications: Bridges, wind turbine flanges

Characteristics: High strength, anti-vibration stability

Grade 12.9:

Tensile Strength: ≥ 1200 MPa

Yield Strength: ≥ 1080 MPa

Materials: 40CrNiMoA

Applications: Aerospace, heavy machinery

Characteristics: Super high strength and toughness

Bolt Selection Recommendations:

General structures: Grade 8.8 is sufficient.

Bridges and wind towers: Grade 10.9 is recommended.

Precision or high-impact parts: Grade 12.9 is ideal.

Case Study:

In a wind turbine tower, switching from 8.8-grade bolts to 10.9-grade bolts improved the preload stability by 30% and extended the maintenance cycle by 1.5 times.

How Are High-Strength Bolts Made?

High-strength bolts are not made by chance; they are the result of several key upgrades:

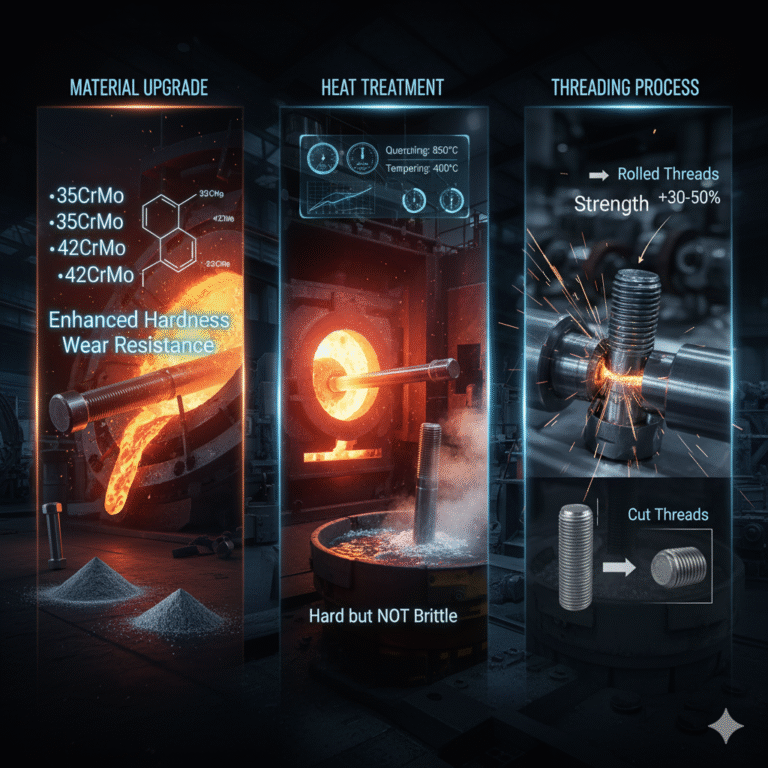

Material Upgrade:

Standard bolts are usually made from low-carbon steel (Q235), which is soft and lacks strength.

High-strength bolts use higher-grade alloy steels like:

35CrMo / 42CrMo: These materials are enriched with chromium and molybdenum, enhancing their hardness and wear resistance.

40CrNiMoA: Adding nickel improves toughness.

35CrMoV: This offers superior fatigue resistance.

For example, 42CrMo steel has a tensile strength up to 1000 MPa, 2.7 times stronger than standard Q235 steel.

Heat Treatment: Hard but Not Brittle:

The core process of creating high-strength bolts involves quenching and tempering:

Quenching: Heating to 850–900°C and then rapidly cooling to form a hard martensitic structure.

Tempering: Reheating to 350–550°C to soften the steel slightly, balancing strength and toughness.

For instance, grade 8.8 bolts are tempered at around 500°C, while grade 12.9 bolts are tempered at about 400°C.

Threading Process:

Standard bolts: Have cut threads, which sever the metal fibers, making them prone to breaking.

High-strength bolts: Use rolled threads, which allow the metal fibers to remain continuous, boosting strength by 30–50%.

Benefits of High-Strength Bolts:

Higher accuracy (tolerances up to 6g grade)

Smoother surface finish (Ra ≤ 1.6 μm)

Significantly improved fatigue resistance

Less prone to rusting and loosening, making them highly reliable in high-vibration environments.

How to Choose the Right Bolt: A Simple 3-Step Guide

Determine the Load Type:

Static Load: Grade 8.8 bolts are sufficient.

Dynamic Load or Vibration: Grade 10.9 bolts are recommended.

Impact or Precision: Grade 12.9 is ideal.

Evaluate the Structural Importance:

Secondary connections: Use standard bolts.

Critical load-bearing components: Opt for high-strength bolts.

Control Preload:

Insufficient preload can lead to loosening, while excessive preload may cause breakage.

For instance, the recommended preload for grade 10.9 bolts is 0.7–0.8 × yield strength.

Conclusion: Bolts Are the Silent Guardians of Safety

The numbers on a bolt’s head are more than just labels—they represent a promise of safety. They ensure that bridges don’t collapse, wind towers stay stable, and machinery continues to run smoothly. Engineers who understand these numbers truly understand structures. Because behind every 8.8 grade bolt, there’s 20 tons of trust.