Introduction to Analog Signals

Analog signals are physical quantities that change continuously over time, such as voltage, current, pressure, speed, and flow rate. These signals are widely used in industrial automation for sensing, monitoring, and controlling physical parameters. Common examples include 0–10V voltage signals and 4–20mA current signals, which can be processed using Programmable Logic Controller (PLC) analog modules. Through sampling and quantization, these analog signals are converted into digital signals for further processing and analysis.

Key Concepts of Analog Signals

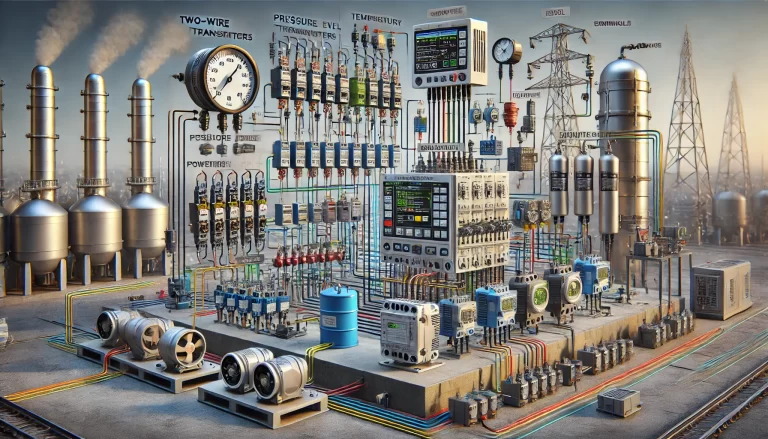

To understand analog signal processing, it is essential to grasp several fundamental concepts, including sensors, actuators, Analog-to-Digital Converters (ADC), and Digital-to-Analog Converters (DAC).

Sensors

Sensors detect and respond to environmental inputs such as light, heat, motion, humidity, or pressure. A sensor typically comprises a sensitive element and a transducer. The sensitive element captures the physical parameter, while the transducer converts it into an electrical signal, which may be either analog or digital, depending on the sensor’s design.

Examples include:- Temperature Sensors (e.g., thermocouples, resistance temperature detectors)

- Pressure Sensors

- Humidity Sensors

- Liquid Level and Material Level Sensors

Actuators

Actuators convert electrical signals into physical action. They are used to control devices such as valves, motors, and pumps based on signal inputs, often originating from the processed sensor data.ADC and DAC

- ADC (Analog-to-Digital Converter): Converts continuous analog signals into discrete digital signals for processing in digital control systems. In a PLC, this function corresponds to the analog input module.

- DAC (Digital-to-Analog Converter): Converts digital signals back into analog signals, typically for output to control equipment like motors and valves.

Sensor Types and Applications

Liquid Level Sensors

Liquid level sensors measure the height of liquids in tanks or containers and convert the measurements into analog signals for monitoring and control. Common types include:

Float-Type Level Sensors

Measure liquid height by detecting the position of a floating object. The float’s movement is converted into an electrical signal.Ultrasonic Level Sensors

Utilize the propagation speed of ultrasonic waves in liquids to measure level height.Radar Level Sensors

Employ radar waves to penetrate media and reflect back for level detection.

Applications: These sensors are extensively used in industries such as oil refining, food processing, chemical production, water treatment, pharmaceuticals, power generation, and shipbuilding.

Material Level Sensors

Material level sensors measure the height of solids or granules in storage tanks or silos. Examples include:

Capacitive Level Sensors

Detect changes in capacitance caused by the material level between sensor plates.Ultrasonic Level Sensors

Measure the propagation time of ultrasonic waves between the material surface and the sensor.Radar Level Sensors

Use microwave radar technology for accurate level measurement.

Analog Signal Standards and Their Significance

Common Signal Types

- Voltage Signals: Typical ranges include 0–10V, -10–+10V, and 0–5V. Among these, 0–10V is the most commonly used.

- Current Signals: Common ranges include 0–20mA, 4–20mA, and -20–+20mA, with 4–20mA being the most prevalent due to its advantages.

Why 4–20mA?

- Resilience to Interference: Current signals are less prone to electromagnetic interference, especially during long-distance transmission.

- Fault Detection: A signal of 0mA could indicate a cable break or equipment malfunction, whereas 4mA serves as a baseline for operational status.

The Importance of Signal Conversion

Signal conversion is a critical step in analog control systems. For example, converting a 0–10V voltage signal involves translating the real-world measurement range into a corresponding analog value, digitizing it for processing, and then converting it back for output. The precision of this process ensures accurate control and monitoring.

Applications of Analog Outputs

Analog outputs are used for controlling various devices in industrial settings, such as:

- Speed of Variable Frequency Drives (VFDs)

- Torque and Speed of Servo Motors

- Valve Positions

By modulating these parameters, systems can achieve precise control over processes such as fluid flow, conveyor speed, and machine operation.

Challenges and Best Practices

Challenges

- Susceptibility to noise in voltage signals during long-distance transmission.

- Calibration complexities in certain environments.

Best Practices

- Use shielded cables to minimize noise.

- Prefer current signals for long-distance transmission.

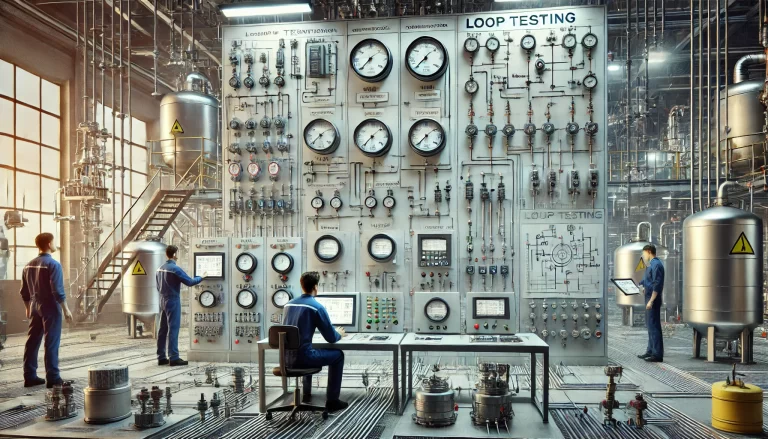

- Regularly calibrate and test sensors to ensure accurate signal conversion and reliability.

Conclusion

Analog signals form the backbone of many industrial automation systems, bridging the physical and digital worlds. From sensors to actuators, ADCs to DACs, these signals enable precise control and monitoring of processes. Their applications span industries such as manufacturing, energy, water treatment, and more, underscoring their versatility and importance. By understanding the concepts, tools, and techniques associated with analog signals, engineers and technicians can design and implement efficient automation systems tailored to specific operational needs.