Ultrasonic level sensors are widely used in the food and beverage industry for applications such as tank level monitoring, filling line control, and ingredient inventory management. However, selecting the right sensor for hygienic environments requires careful consideration of performance, compatibility, and regulatory standards.

This guide outlines the key selection criteria, environmental compatibility, and application-specific recommendations to ensure safe, accurate, and reliable level measurement in food processing facilities.

1. Core Selection Criteria

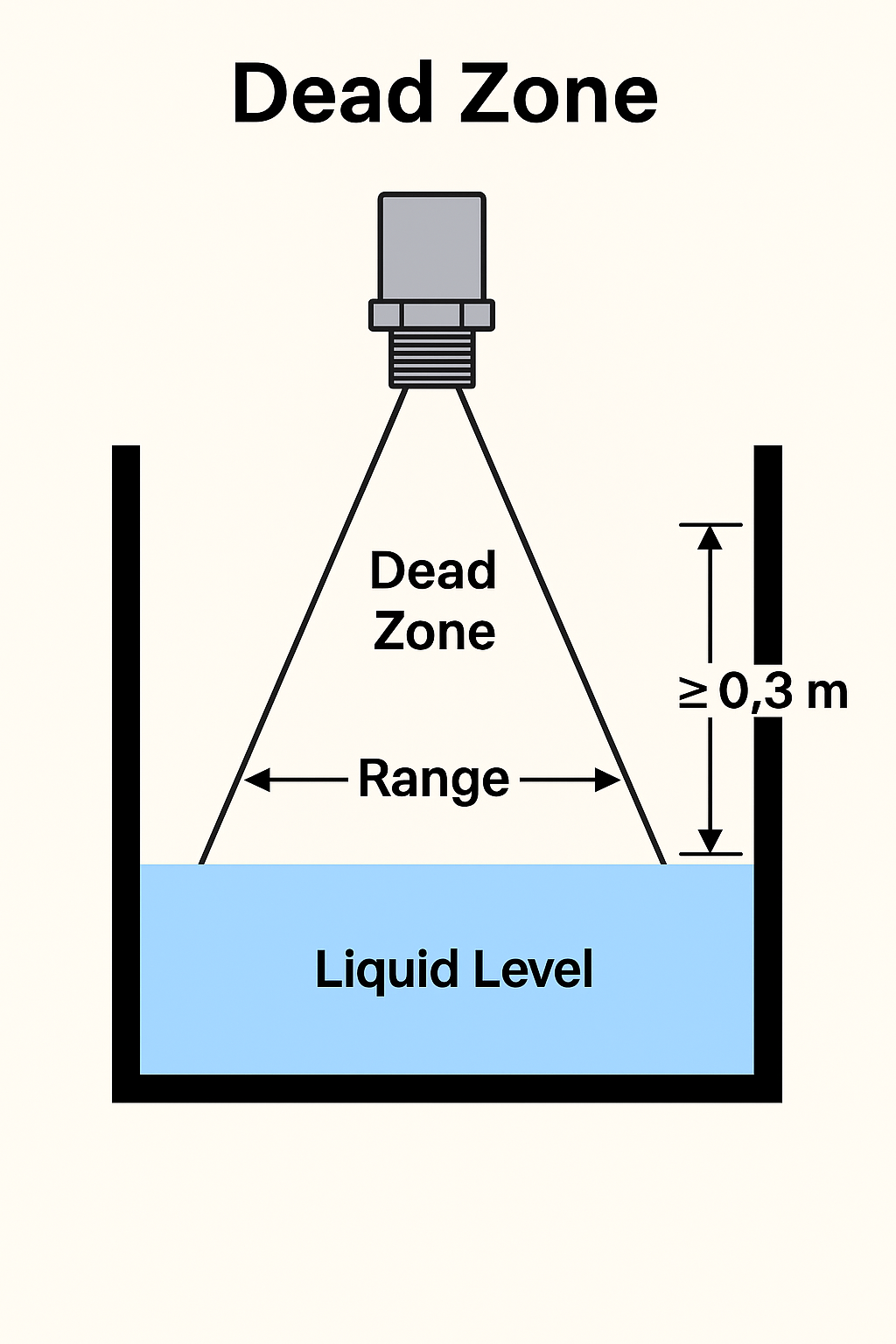

1.1 Range and Dead Zone Matching

Range Utilization: The actual liquid level should fall within 60–80% of the sensor’s full range. For example, a 10-meter sensor is ideally suited for liquid levels between 6–8 meters. Avoid operating at the extreme ends of the range to reduce signal attenuation.

Dead Zone Avoidance: Ensure the maximum liquid level remains at least the dead zone distance below the sensor face (e.g., ≥0.3 m) to avoid false readings due to near-field reflection loss.

1.2 Accuracy and Resolution Requirements

Filling Applications: Require high-precision models with ≤±0.25% accuracy and ≤1 mm resolution for reliable batch and dosage control.

Storage Monitoring: Standard accuracy of ±0.5% is typically sufficient, with emphasis on anti-interference performance.

2. Media and Environmental Compatibility

2.1 Material and Hygienic Standards

Sensor Head Material: Select 316L stainless steel or PVDF housings that comply with FDA and EHEDG food contact certifications.

Ingress Protection: Choose at least IP65-rated sensors. For acidic environments or wet processes, IP67 or higher is recommended.

2.2 Process Environment Suitability

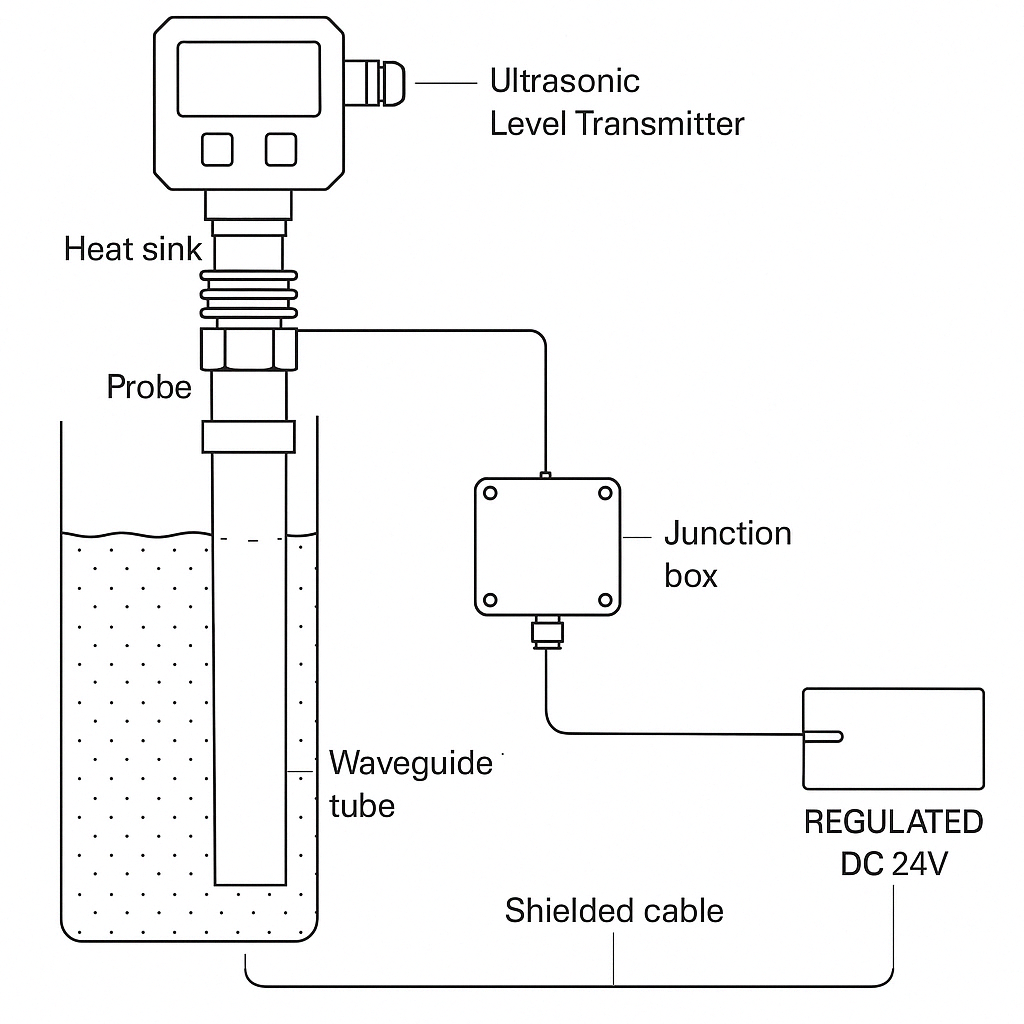

Temperature Range: Ensure the probe material withstands process temperatures (e.g., -20°C to +80°C). For high-heat environments (e.g., sterilization tanks), use a remote (split-type) configuration to isolate electronics.

Foam and Steam Resistance: Use high-frequency models (40–80 kHz) with narrow beam angles (4–6°) to reduce signal scattering and improve penetration through vapor or foam layers.

3. Functional Features and Power Supply

3.1 Signal Output and Communication

Basic Installations: Use 2-wire 4–20mA analog output with 24V DC supply for small-scale tanks or simple monitoring.

Automated Systems: Opt for 4-wire sensors supporting RS485/Modbus for seamless PLC or SCADA integration, enabling pump or valve automation.

3.2 Extended Functional Capabilities

Sanitary Cleaning: Choose sensors with self-cleaning coatings or removable probes to facilitate CIP/SIP (Clean-in-Place/Sterilize-in-Place) operations.

Alarm Outputs: Configure high/low level relay alarms (e.g., AC220V/3A) for overflow or empty tank protection.

4. Installation and Maintenance Considerations

4.1 Mounting Methods

Open Tanks: Use flange or threaded connections, ensuring the sensor is installed vertically above the liquid surface and at least 30 cm away from the tank wall to avoid echo interference.

Closed Vessels: Install via top access ports, and use split-type designs for harsh or high-temperature environments.

4.2 Maintenance Friendliness

Zero Point Calibration: Select models with automatic temperature compensation to reduce the need for frequent manual recalibration.

Error Diagnostics: Prefer sensors with LCD displays showing real-time signal strength and diagnostic codes for quick troubleshooting.

5. Application Scenarios and Model Recommendations

| Scenario | Recommended Features |

|---|---|

| Dairy Storage Tanks | 4-wire, IP67, 40kHz frequency, Modbus protocol (e.g., YEH-Z series or equivalent) |

| Juice Filling Line | 2-wire, ±0.25% accuracy, PVDF probe, self-cleaning (e.g., CHAVEZ customized version) |

| High-Temp Sterilizers | Split-type, up to 150°C, RS485 output, 316L SS sensor head (custom build required) |

| Small Water Tanks | Budget-friendly 2-wire, IP65, 10 m range (e.g., entry-level ABS housing models) |

Note: Actual model selection should be confirmed with the supplier based on detailed process conditions.

6. Common Pitfalls and Selection Mistakes

6.1 Unsuitable Media

Viscous Liquids (e.g., Honey): Standard ultrasonic sensors are not recommended. Consider guided wave radar or contact sensors instead.

Highly Volatile Media (e.g., Alcohol): Use sealed probes to prevent vapor ingress and internal circuit damage.

6.2 Parameter Mismatches

Pressure Limits: Ultrasonic sensors are generally limited to <4 bar. For high-pressure applications, use pressure-resistant housing or alternative technology.

Power Supply Compatibility: Always confirm the sensor’s power requirements (e.g., AC220V vs. DC24V) to prevent short circuits or device damage.

Conclusion

By evaluating factors such as range, hygiene compliance, media compatibility, and communication interface, food processors can select ultrasonic level sensors that meet both operational and regulatory requirements. Prioritizing signal stability, cleaning convenience, and system integration helps ensure long-term measurement reliability and food safety compliance.