1. Introduction

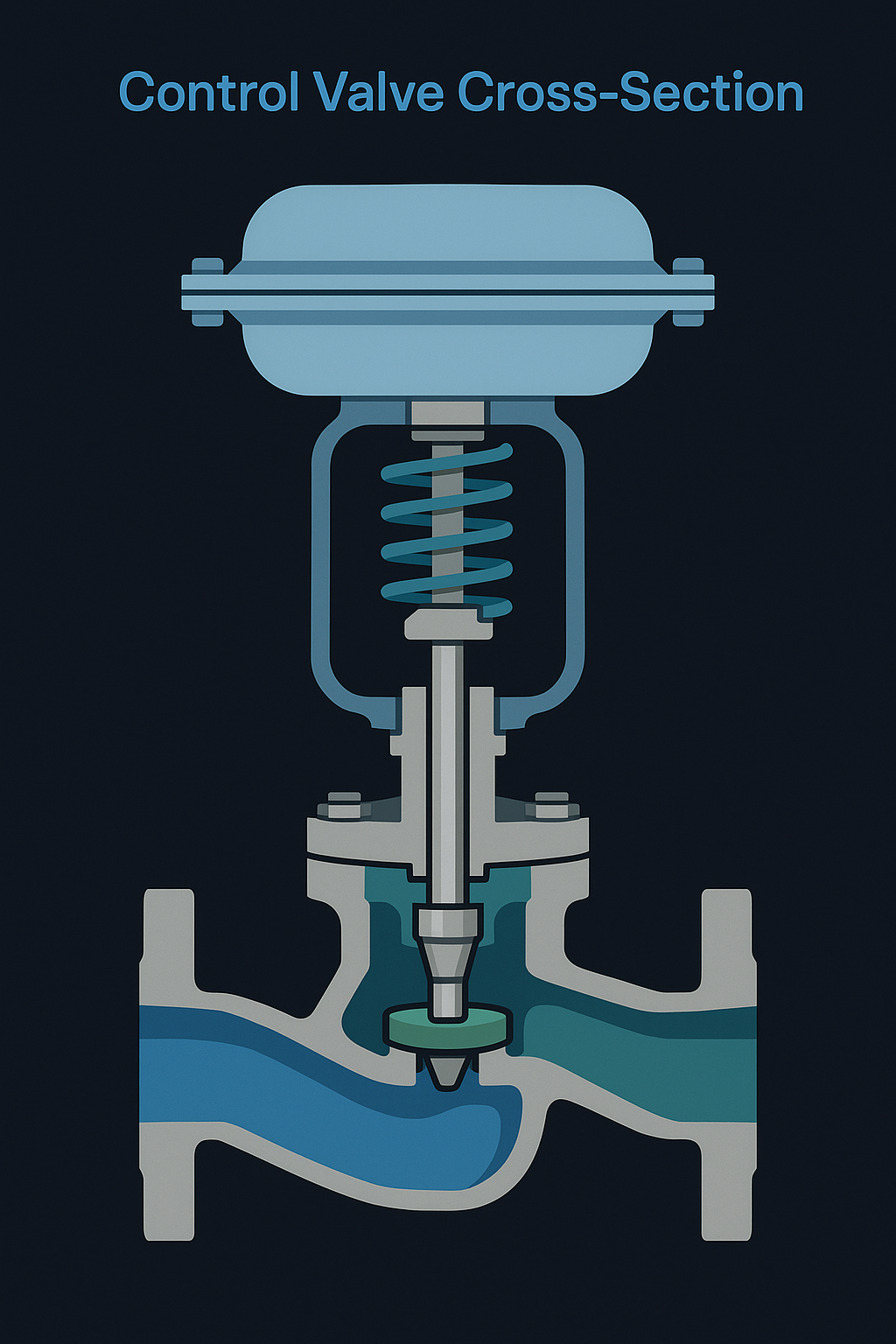

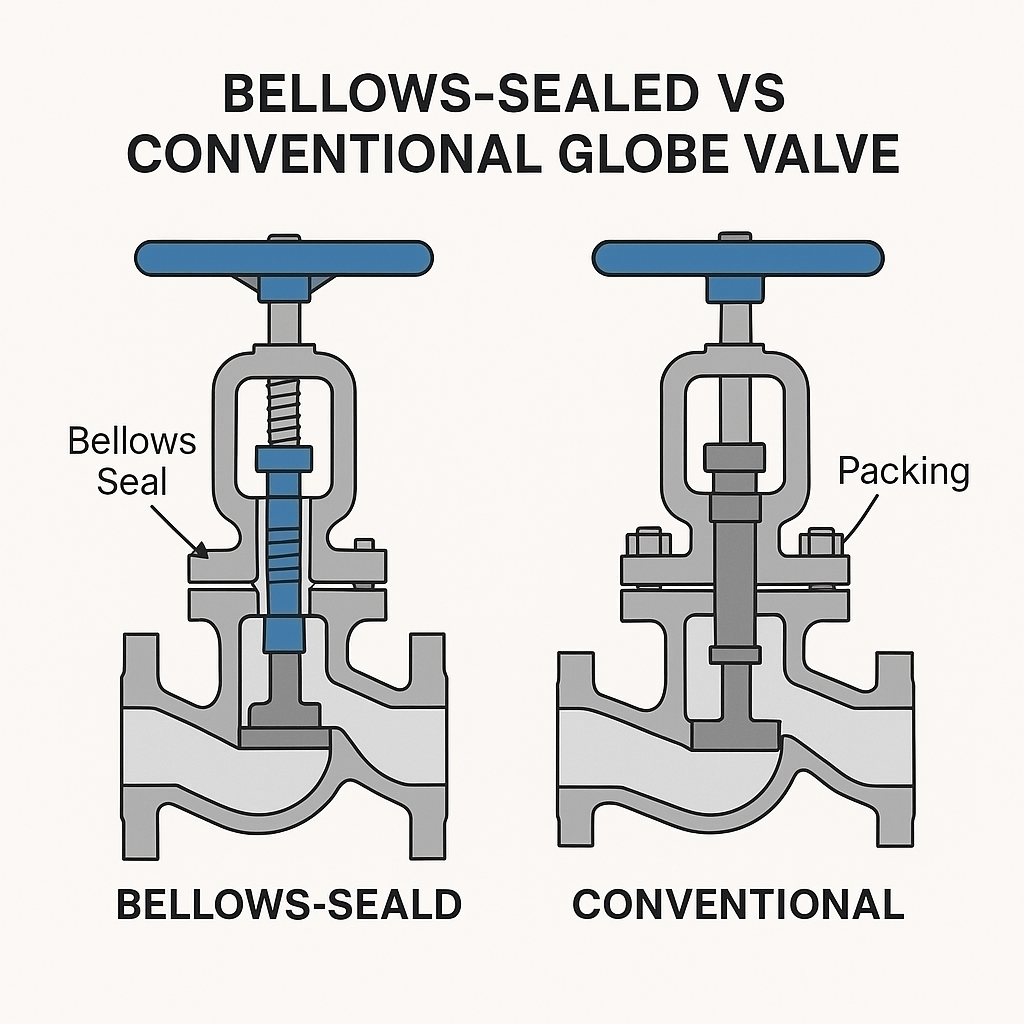

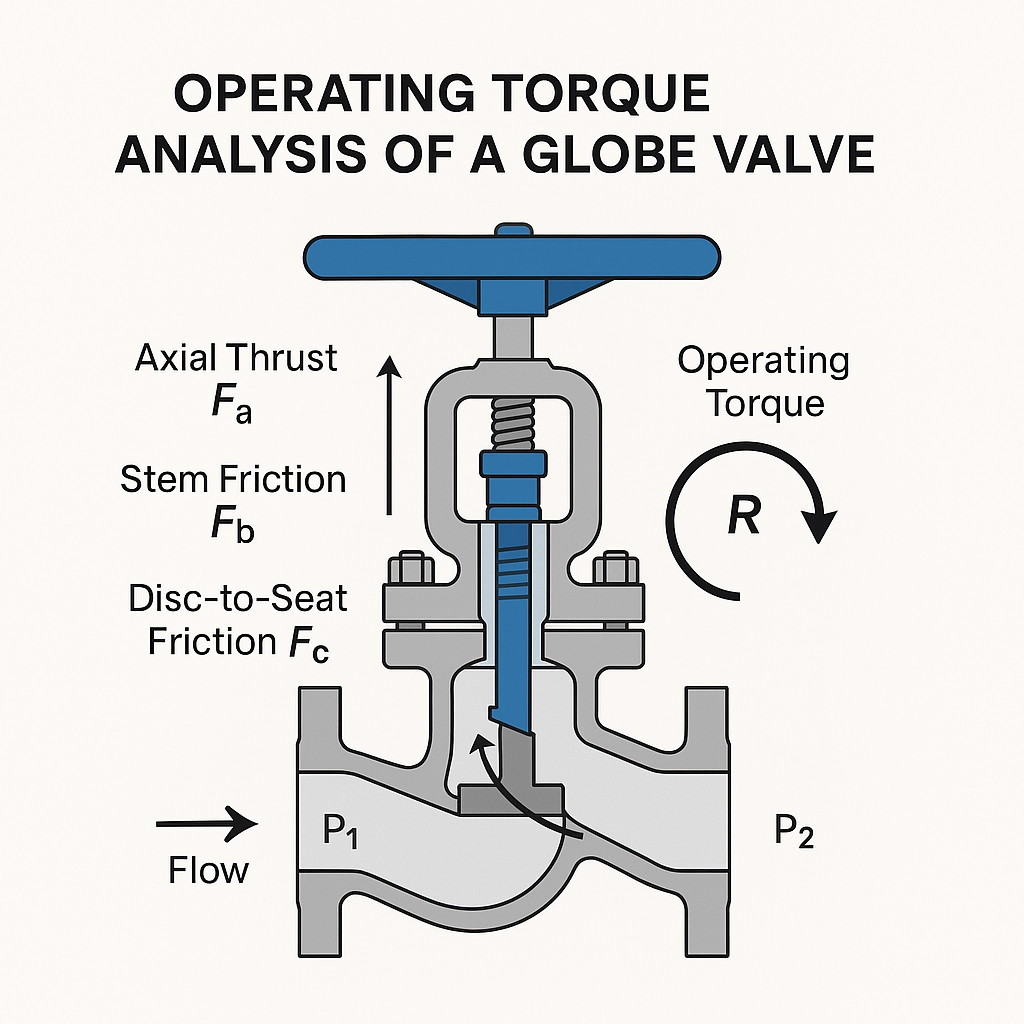

Control valves are the final control elements in process automation, typically consisting of an actuator, valve body, internal trim, and accessories.

Accessories such as positioners, solenoid valves, quick exhaust valves, and air reservoirs are critical in ensuring reliability, safety, and fast response. This document summarizes the key accessories and demonstrates typical pneumatic circuit configurations for anti-surge control systems.

2. Classification of Control Valve Accessories

2.1 Signal & Control Devices

Valve Positioner

Types: pneumatic, electro-pneumatic, smart positioners

Function: ensures accurate valve position through feedback control

Solenoid Valve

Used in remote control, interlock, and emergency shutdown

Configurations: direct-acting, pilot-operated, 3/2-way, 5/2-way

Limit Switch

Provides ON/OFF position feedback for interlocks and alarms

Figure 3 — Mechanical vs. Proximity Limit Switch

Valve Position Transmitter

Converts stem travel or angle into 4–20 mA signal for monitoring

2.2 Air Supply & Pressure Regulation

Filter Regulator (FR)

Removes impurities, stabilizes supply pressure

Air Reservoir (Tank)

Provides backup air supply in case of source failure

Ensures valve completes fail-safe action

Check Valve

Allows airflow in one direction, prevents backflow

Quick Exhaust Valve

Accelerates actuator response by venting directly to atmosphere

Volume Booster / Amplifier

Increases air flow to actuator for rapid stroke response

Air Lock Valve (Fail Position Holder)

Maintains valve position during air failure

3. Typical Pneumatic Circuits

3.1 Anti-Surge Valve for Compressors (≤14″ Size)

Normal Operation:

4–20 mA signal → Positioner → Solenoid Valve → Booster → Actuator

Valve modulates smoothly according to signal

Fast-Open Function:

Solenoid de-energizes → Quick exhaust valve + solenoid venting → Valve rapidly opens

3.2 Anti-Surge Valve for Large Compressors (>20″ Size)

Normal Operation:

Digital positioner output → Pneumatic relay (377) → Booster → Double-acting actuator

Fast-Open Function:

Solenoid & relay cut air supply, air reservoir discharges → Quick exhaust venting → Valve rapidly opens

4. Engineering Notes & Best Practices

Select accessories according to safety integrity level (SIL) requirements

Ensure explosion-proof rating and IP protection level meet site standards

Redundancy:

Safety priority: series logic for solenoid valves

Availability priority: parallel logic

Install pressure gauges for monitoring air lock and actuator chamber pressures

Reserve space for maintenance and inspection when installing air tanks and pipelines

5. Conclusion

A properly designed pneumatic circuit with suitable valve accessories enhances:

Safety (fail-safe positioning, interlock reliability)

Responsiveness (fast opening/closing functions)

Reliability (clean air supply, redundancy design)

Maintainability (standardized accessories, clear layout)

By understanding and correctly applying these components, engineers can ensure stable process control and protect critical equipment such as compressors.