Analytical instruments are an essential part of industrial automation, used to detect and analyze the composition, concentration, or other important chemical and physical parameters of substances. These instruments find widespread applications in industries such as chemical processing, pharmaceuticals, environmental protection, and food processing. They help companies improve product quality, optimize production processes, and ensure safe operations. Analytical instruments come in various types, each designed for specific applications and measurement needs. Below are some of the most common types.

1. Gas Analyzers

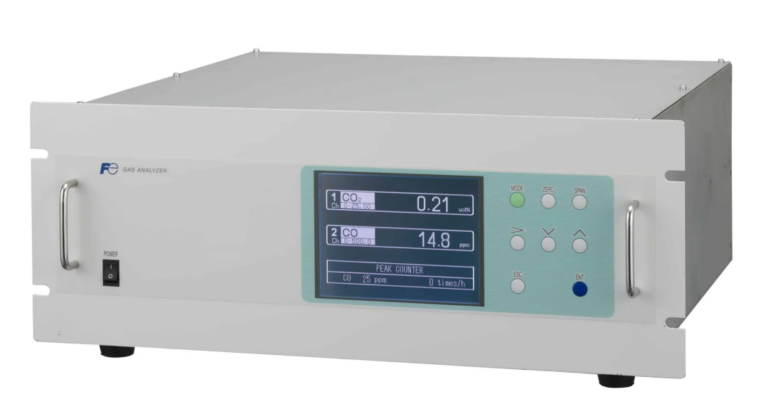

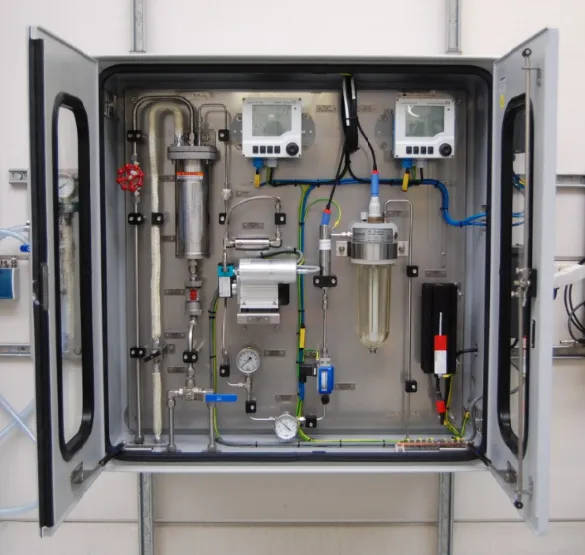

Gas analyzers are used to detect and analyze the composition and concentration of gases in a sample. They are commonly used in environmental monitoring, industrial emissions control, and safety monitoring. Some of the common gas analyzers include:

Infrared Gas Analyzer (IRGA): This analyzer uses the absorption properties of infrared light to analyze gases, especially suitable for measuring gases such as carbon dioxide, carbon monoxide, methane, and nitrogen. It’s widely used for environmental monitoring and industrial waste gas testing.

Chemiluminescence Analyzer (CLD): This type of analyzer detects the light emitted during chemical reactions, often used for detecting nitrogen oxides (NOx). It’s commonly employed in air quality monitoring and emission control.

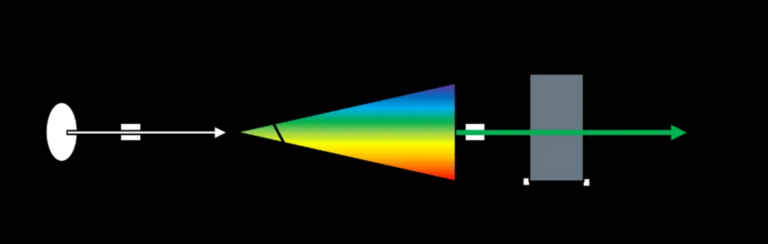

Gas Chromatograph (GC): Based on gas chromatography principles, this instrument separates the components of a gas mixture and quantitatively analyzes them. It is widely used in petrochemical, environmental testing, and food analysis. The GC can precisely identify complex components in gas samples, particularly volatile organic compounds (VOCs) and air pollutants.

Electrochemical Gas Analyzer: This analyzer uses a chemical reaction with electrodes to generate a current that is used to determine the gas composition. It is frequently used for monitoring gases like oxygen, carbon monoxide, and hydrogen, commonly applied in industrial gas monitoring, indoor air quality testing, and laboratory analysis.

Example: A factory that produces chemical products often uses IRGA to monitor CO2 emissions to comply with environmental regulations.

2. Liquid Analyzers

Liquid analyzers are designed to detect and analyze various chemical parameters in liquid samples, including pH, concentration, and specific ions. They are widely used in water quality monitoring, the pharmaceutical industry, and food processing. Common liquid analyzers include:

pH Meter: This is used to measure the acidity or alkalinity of a liquid solution and is one of the most common instruments in liquid analysis. It is commonly used in environmental monitoring, water treatment, and chemical analysis.

Conductivity Meter: This measures the electrical conductivity of a liquid, which is directly related to its ion concentration. It’s widely used in water treatment, food industry, and pharmaceuticals.

Ion-Selective Electrode (ISE): This analyzer is used to measure the concentration of specific ions, such as sodium, calcium, and chloride ions. It is commonly used in water quality analysis, chemical laboratories, and food safety monitoring.

Spectrophotometer: This device measures the absorbance or transmission of light at specific wavelengths, helping to determine the concentration of chemical substances in a sample. It’s widely used in water analysis, food safety testing, and environmental monitoring.

Example: In the pharmaceutical industry, a spectrophotometer is used to ensure the correct concentration of active ingredients in drug formulations.

3. Gas Chromatograph (GC)

Gas chromatography is a widely used technique for analyzing gas and volatile liquid mixtures. This instrument vaporizes the sample, which is then distributed between a stationary phase and a mobile phase. It separates components based on their retention times, and each component is quantified. GC is typically used in petrochemical, environmental monitoring, and food safety analysis.

Example: A laboratory analyzing the air quality around an industrial plant uses a GC to separate and measure trace pollutants like benzene and toluene in the atmosphere.

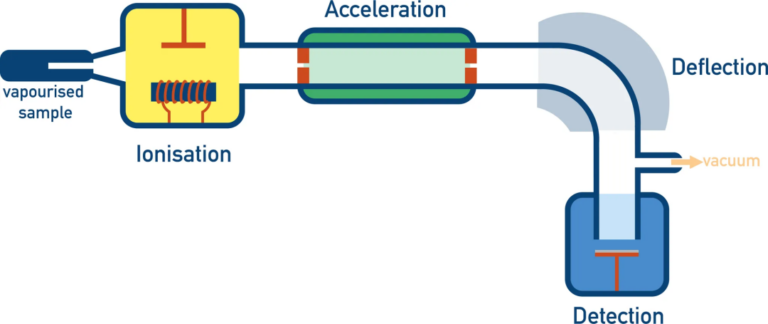

4. Mass Spectrometer (MS)

A mass spectrometer analyzes substances based on the mass-to-charge ratio (m/z) of their ions. Often paired with gas or liquid chromatography, it offers both qualitative and quantitative analysis, making it ideal for complex sample analysis. MS is used in environmental monitoring, drug testing, food safety, and chemical research.

Gas Chromatography-Mass Spectrometry (GC-MS): This combined system is used for precise analysis of volatile organic compounds (VOCs). It is particularly useful in environmental monitoring and food safety analysis.

Liquid Chromatography-Mass Spectrometry (LC-MS): LC-MS is suitable for analyzing compounds that are non-volatile or heat-sensitive, such as drugs, proteins, and biological samples.

Example: In forensic laboratories, GC-MS is used to identify substances like drugs and toxins in blood or urine samples.

5. Spectroscopic Analyzers

Spectroscopic analyzers work by measuring the absorption, reflection, or emission of light by substances to analyze their composition. Common spectroscopic analyzers include:

Atomic Absorption Spectrometer (AAS): AAS analyzes the concentration of metal elements in a sample by measuring the absorption of light at specific wavelengths. It is used in environmental monitoring, food safety, and mineral analysis.

Atomic Emission Spectrometer (AES): AES measures the light emitted by substances at high temperatures, providing both qualitative and quantitative analysis. It’s typically used for metal element analysis.

UV-Vis Spectrophotometer: This device measures the absorbance of UV and visible light by a sample, used to analyze the concentration and purity of organic compounds. It is commonly used in chemical analysis, pharmaceutical testing, and water quality monitoring.

Example: A wastewater treatment facility uses AAS to monitor heavy metals like lead and arsenic in the water to ensure safety standards are met.

6. Thermal Analysis Instruments

Thermal analysis instruments measure the thermal properties of materials during heating or cooling. They are widely used in materials science and chemical analysis. Common thermal analysis instruments include:

Differential Scanning Calorimeter (DSC): DSC measures the heat flow difference between a sample and a reference material, helping to determine thermal properties like melting points and glass transition temperatures.

Thermogravimetric Analyzer (TGA): TGA measures the mass change of a sample as it is heated, providing insights into the sample’s thermal stability and composition.

Dilatometer (DIL): This instrument measures changes in the volume of materials as they are heated, commonly used to study the properties of materials under high-temperature conditions.

Example: A manufacturer of polymers uses TGA to assess the thermal stability of their raw materials before production.

7. Flow Injection Analyzer (FIA)

The Flow Injection Analyzer is a highly automated system used to analyze the chemical composition of liquid samples. The system injects a sample into a flowing carrier liquid, and the analysis is based on the time and concentration of the reaction products. FIA is widely used in water quality testing and food analysis due to its high sensitivity and automation.

Example: A food quality control laboratory uses FIA to quickly analyze the concentration of preservatives in beverages.

Conclusion

Analytical instruments are diverse and play a critical role in industrial production, environmental monitoring, research, and quality control. Depending on the measurement principles and applications, these instruments can precisely analyze various parameters such as composition, concentration, temperature, and pressure. With technological advancements, analytical instruments continue to improve in accuracy, reliability, and automation, providing more efficient solutions across industries.