How they work

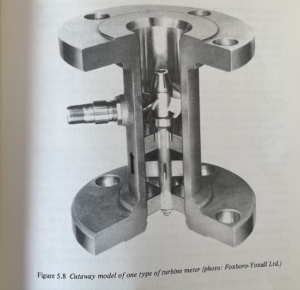

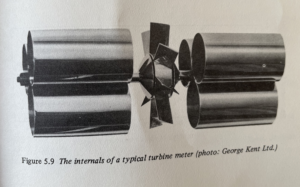

A turbine meter is a name given to one particular type of rotating flow meter. It consists of a short length of pipe in the center of which there are two bearings supported by spiders. A propeller, large enough to fill the cross-section of the pipe almost completely, is mounted so that it can spin freely on these central bearings, as shown in Figure 5.8 and 5.9. Either the propeller blades are themselves made of magnetic material or a small magnet is inserted in the tip of each blade, and their passage past a pick-up mounted in the wall of the pipe causes electrical pulses to be emitted. If these pulses are passed into a pulse counter the total count is an indication of the total volume which has been delivered through the turbine meter, and if they are passed into a frequency analyzer the frequency is an indication of the volumetric flow rate.

Large meters rotate more slowly, and hence they tend to have a lower pulse generation rate. If a higher frequency of pulse generation is required, they may be fitted with multiple pick-ups or with a shroud ring containing a number of magnets. Also, electronic pulse multipliers are beginning to be used for this purpose, but it has not yet been shown conclusively that their accuracy is anything like that of the older methods.

The installation of three pick-ups in one meter has an additional advantage:

their output can be used to check whether spurious pulses (from electrical

interference) are being collected. For this purpose, the outputs from two of the

pulses are fed, additively, into one counter, and the output from the other pick-

up into a second counter. If the count on the first counter is double that of the second, this means that all is well; but if it is significantly less than double, then electrical interference may be inferred.

The weakest spot in a turbine meter is still the bearing, even though modern bearing materials give much less trouble than those of a few years ago. The bearing always has to support the weight of the rotor, and in some turbine meters, the bearing also has to support some of the end thrust caused by the drag of the flowing liquid on the blades, although this thrust is taken up hydrodynamically in the best-designed turbine meters. In large turbine meters and errors arising from bearing friction become relatively insignificant; in very small turbine meters, however, bearing friction and geometrical effects can lead to considerable inaccuracies.

Other design parameters affecting turbine meter performance include the size

of the hub, the clearance between the blade tip and pipe wall, and the shape, size, and spacing of the blades.

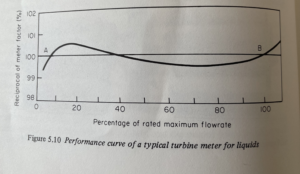

The performance of a turbine meter cannot be predicted very accurately from

hydrodynamic theory. Consequently, it is necessary for each individual turbine

meter to be calibrated, so that the relationship between the number of pulses

emitted and the volume of fluid passed can be determined experimentally. This

results in a calibration curve of the form shown in Figure 5.10. A turbine meter

is said to have ‘linear output’ over the range A-B in Figure 5. 10, where the

volume of liquid passing through the meter is almost exactly proportional to

the number of pulses emitted. The meter becomes inaccurate and cannot be

Used to give reliable results at flow rates less than those corresponding to

Point A because at these lower flow rates bearing fiction becomes too great to be tolerated. At flow rates higher than those corresponding to point B, the meter becomes unusable because of fluid effects such as excessive hydrodynamic drag and cavitation.

For metering liquids such as milk, turbine meters are available which can easily be taken to pieces for cleaning. Another special form of turbine meter is the bi-directional type, for use in pipes where the flow is liable to be reversed on occasions.

Points to Watch when Buying

(a) The turbine meter is a high-quality device intended mainly for applications

where accurate measurement of flow rate and/or total quantity is needed, and

especially for metering large quantities of petroleum and its products. Does

your application justify the use of this rather costly type of meter?

(b) Examine the calibration curve supplied by the manufacturer. Is the meter

linear to within +0.25% over a suitable range of flow rates?

(c) Is the meter certified as suitable for use with the fluid for which itis

intended, and at the anticipated pressure and temperature?

(d) Does the meter have straight blades o helical blades? Straight-bladed meters appear to be less affected by variations in velocity profile, but helical-bladed meters are generally less affected by variations in viscosity.

Points to Watch when Using

(a) Because your turbine meter has been designed for use with liquids, never blow out the line in which it is installed with compressed air or steam since this would probably cause it to overspeed and serious damage can result.

(b) If dirty liquids such as crude oil are being metered, it is essential to protect the meter by installing a coarse filter or strainer upstream of it.

(c) Power cables, motors, switchgear, etc., produce electromagnetic radiation. This can be picked up by the pulse counter, causing it to over-read. To avoid such errors, follow the advice in section 10.9.2 and see also the third paragraph of section 5.3.1.

(d) Make sure there is sufficient pressure in the line to avoid cavitation, installing a back-pressure valve if necessary. The standard codes of practice and manufacturers’ handbooks give the necessary figures. Remember that hydrocarbons cavitate more readily than water so that higher back-pressures are generally needed with oils and fuels.

(e) Follow the standard practice with regard to the required length of straight pipe upstream and downstream, and install a flow straightener if necessary.

(f) If the meter is to be calibrated in situ against a pipe prover, make sure that the prover is connected downstream of the meter, not upstream.