For liquid turbine flow meter installation guidelines

Pipes must be fully filled with liquids. It is essential that pipes remain fully filled at all times,

otherwise, flow rate indications may be affected and measurement errors may be caused.

Avoid Air Bubbles. If air bubbles enter a measurement pipe, flow rate indications may be affected and measurement errors may be caused.

- Avoid all pipe locations where the flow is pulsating, such as on the outlet side of the piston or diaphragm pumps.

- Avoid locations near equipment producing electrical interference such as electric motors, transformers, variable frequency, etc.

- Install the meter with enough room for future access for maintenance purposes.

For gas turbine flow meter installation guidelines

Mounting Positions

Avoid all pipe locations where the flow is pulsating, such as on the outlet side of the piston or diaphragm pumps.

Avoid locations near equipment producing electrical interference such as electric motors, transformers, variable frequency, etc.

Install the meter with enough room for future access for maintenance purposes.

Warning: Precaution for direct sunshine and rain when the meter is installed outside.

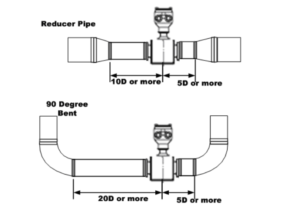

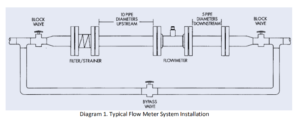

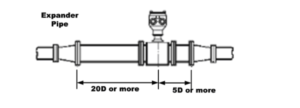

Required Lengths of Straight Runs

Flow-altering devices such as elbows, valves, and reducers can affect accuracy. See the diagram below for a typical flow meter system installation.

The recommended guidelines are given to enhance accuracy and maximize performance.

The distance given here are minimum requirements; double them for desired straight pipe lengths.

Upstream: allow a minimum straight pipe length of at least 10 times the internal diameter of the pipe.

For example, with the 50mm pipe, there should be 500mm of straight pipe immediately upstream.

The desired upstream straight pipe length is 1000mm.

Downstream: allow a minimum straight pipe length of at least 5 times the internal diameter of the pipe. For example, with the 50mm pipe, there should be 250mm of straight pipe immediately upstream. The desired upstream straight pipe length is 500mm.

Special Notice

♦ Foreign material in the liquid being measured can clog the meter’s rotor and adversely affect accuracy. If this problem is anticipated or experienced, install screens to filter impurities from incoming liquids.

♦ To ensure accurate measurement, drain all air from the system before use.

♦ When the meter contains removable cover plates. Leave the cover plate installed unless accessory modules specify removal. Don’t remove the cover plates when the meter is powered, or electrical shock and explosion hazards can be caused.