1. Overview

Brief introduction to tungsten-cobalt alloy (WC-Co) wear-resistant thermocouples, their typical applications, and why they are compared with ceramic, high-chromium cast iron, and bimetallic types.

2. Key Advantages

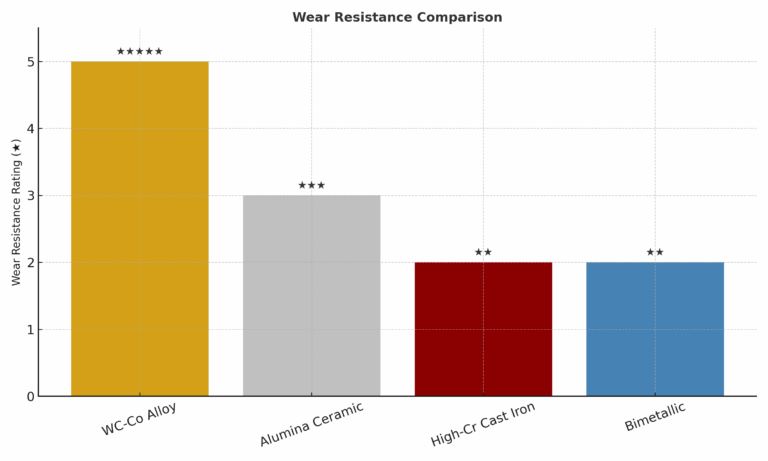

2.1 Superior Wear Resistance – Ideal for High-Hardness Particle Environments

WC-Co hardness: HRC 65–90 (depending on cobalt content)

3–5 times the wear resistance of alumina ceramics (HRC 50–60)

Wear rate in high-speed particle flow (e.g., coal powder pipelines) is only 1/5–1/10 of high-chromium cast iron.

2.2 Excellent High-Temperature Stability

Operating temperature range: –200°C to 1400°C (depending on thermocouple type: K, N, S, etc.)

Maintains hardness and structural integrity at high temperatures

Superior to high-chromium cast iron (loses hardness above 800°C) and bimetallic types (limit ~600°C).

2.3 Better Impact Resistance

Cobalt matrix provides toughness while maintaining hardness

Can withstand medium-intensity impacts without fracture (unlike ceramics)

More durable in vibration and intermittent impact conditions.

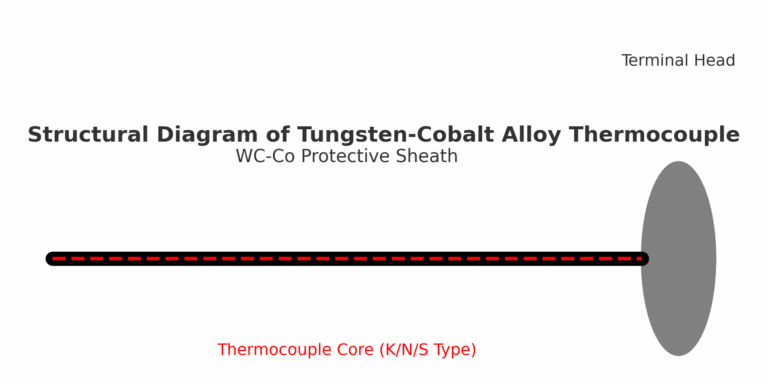

2.4 Flexible Formability – Adaptable to Complex Installations

Powder metallurgy allows shapes such as straight rods, elbows, flanged designs, thin probes

Can be combined with various thermocouple cores (K, N, S)

Suitable for narrow pipelines and irregular reactor structures.

3. Comparative Performance Table

| Property | WC-Co Alloy | Alumina Ceramic | High-Chromium Cast Iron | Bimetallic |

|---|---|---|---|---|

| Hardness (HRC) | 65–90 | 50–60 | 55–65 | 50–60 |

| Wear Resistance | ★★★★★ | ★★★ | ★★ | ★★ |

| Max Temperature (°C) | ~1400 | ~1200 | ~800 | ~600 |

| Impact Resistance | ★★★★ | ★ | ★★★ | ★★★ |

| Formability | High | Low | Medium | Medium |

| Typical Lifespan* | 2–3× ceramic | – | 3–5× cast iron | – |

* Under “high-temperature + high-hardness particles + medium impact” conditions.

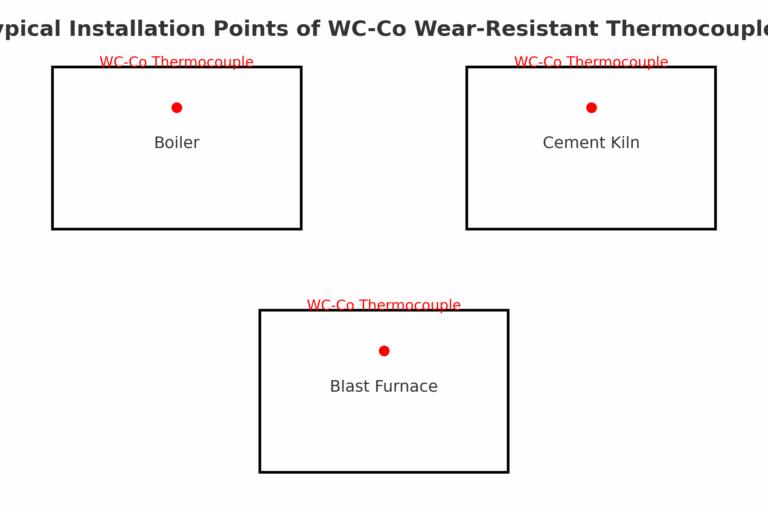

4. Typical Application Scenarios

Power plant boilers

Metallurgical blast furnaces

Cement rotary kilns

Fluidized bed reactors

Waste incinerators

5. Limitations & Selection Notes

Higher cost than cast iron or bimetal types

Corrosion resistance weaker than Hastelloy in strongly corrosive gases (e.g., high-chlorine or high-sulfur environments)

Selection should consider temperature, particle hardness, impact strength, and corrosion factors.