Introduction

Instrumentation failures can significantly impact industrial processes, so prompt and accurate diagnosis is essential. The first step in troubleshooting is to thoroughly understand the working environment, process conditions, and structural characteristics of the instrument. Before starting repairs, collaborate with technical staff to analyze the root causes of the issue.

Additionally, determine whether the instrument plays a role in regulation or interlock systems. Ensure that the process remains stable during maintenance. This article provides detailed troubleshooting techniques for common on-site instruments: thermometers, pressure gauges, flowmeters, and level gauges.

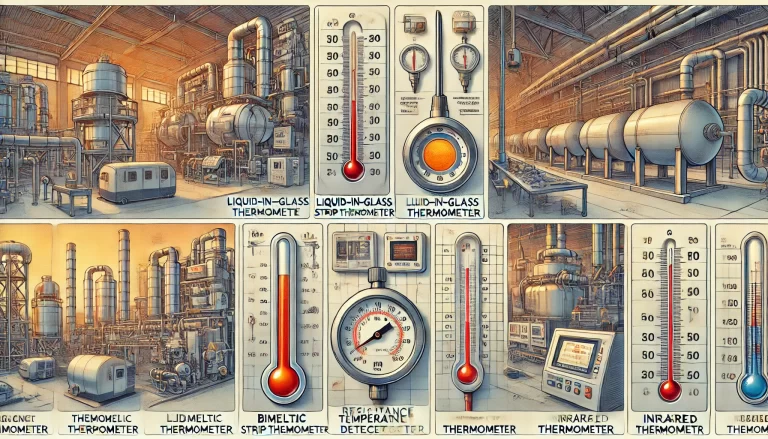

Thermometer Troubleshooting

1. Sudden Temperature Rise

This issue is often caused by:

- Open circuit in thermocouple or resistance temperature detector (RTD): Check connections and wiring.

- Loose terminal connections: Inspect terminal blocks for secure fastening.

- Broken wires: Use a multimeter to measure resistance or millivolt output at different points to identify the fault.

2. Sudden Temperature Drop

Likely reasons include:

- Short circuits in thermocouples or RTDs.

- Shorted wires: Focus on areas prone to bending or external damage, such as connection ports or wire bends.

3. Temperature Fluctuation or Oscillation

Investigate:

- Process operation: Check for irregularities in the control system or changes in system dynamics.

- Control system issues: Evaluate settings of the PID (Proportional-Integral-Derivative) controller for inappropriate parameters.

Pro Tip: Always confirm that environmental factors such as electromagnetic interference or external vibrations are not affecting the measurement.

Pressure Gauge Troubleshooting

1. Sudden Pressure Increase or Decrease (Static Reading)

Causes may include:

- Blocked root valve: Inspect the root valve and purge any obstructions.

- Clogged or restricted impulse lines: Ensure lines are clean and free of foreign material.

- Frozen medium in winter: If applicable, check for frozen liquids in the impulse line.

- Leakage: Examine drain plugs, valves, or tubing connections for leaks.

2. Pressure Fluctuation

Possible reasons:

- Process disturbances: Work with operators to confirm stable input conditions.

- Regulation system malfunctions: Reevaluate the PID parameters or inspect control valves for proper operation.

Flowmeter Troubleshooting

1. Minimal Flow Indication

Potential causes:

- Damaged sensing element: Inspect and replace if necessary.

- Signal transmission issues: Check for short or open circuits in the wiring.

- Obstructions in the positive pressure chamber: Clean the chamber to restore normal function.

- System pressure too low: Confirm process parameters meet operational requirements.

2. Maximum Flow Indication

This issue typically arises from:

- Blocked or leaking negative pressure chamber: Clean the impulse line or repair leaks.

3. Fluctuating Flow Reading

Analyze the following:

- Process instability: Non-regulating parameters often relate to upstream process variations.

- PID control issues: For regulating parameters, adjust PID settings as necessary.

- Air bubbles in impulse lines: Verify the height of liquid in impulse lines and remove trapped air.

Practical Tip: For flowmeters with isolation chambers, ensure equal liquid levels in both positive and negative impulse lines.

Level Gauge Troubleshooting

1. Sudden Increase in Indicated Level

Inspect:

- Negative pressure chamber: Check for blockages, leaks, trapped air, or insufficient liquid.

2. Sudden Decrease in Indicated Level

Verify:

- Positive pressure chamber: Look for similar issues as in the negative pressure chamber.

- Balance valves: Confirm they are fully open to avoid differential pressure misreadings.

3. Discrepancy Between Control Room and Field Readings

Steps to resolve:

- Cross-check field measurements with control room indications.

- Adjust the actual level manually to test the correspondence between both systems.

- Investigate sensor calibration or transmission errors.

4. Frequent Level Fluctuations

- Process variations: Work with process engineers to identify instability in feed or discharge rates.

- PID tuning: Adjust controller settings to smooth out fluctuations.

Comprehensive Troubleshooting Approach

When instrumentation parameters deviate from normal values, follow these steps:

- Collaborate with technical staff to evaluate the entire system, including process conditions and instrumentation performance.

- Check for correlations between the measured parameters and control valves.

- Use a step-by-step diagnosis to isolate and identify the fault.

Key Considerations:

- Always notify the technical team before disabling interlocks to prevent production disruptions.

- Regularly inspect and maintain equipment to minimize the likelihood of failures.

By following these guidelines, you can achieve accurate, efficient, and reliable troubleshooting for on-site instrumentation.

Maintenance Recommendations

To prevent future failures:

- Implement a regular maintenance schedule.

- Train staff on common fault scenarios and response actions.

- Keep spare parts for critical instruments readily available.

By adopting a proactive approach, you can enhance system reliability and reduce downtime.