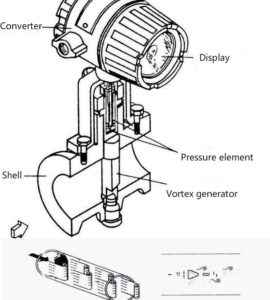

ABSTRACT: In the aspect of failure rate, the vortex flow meter designed and produced by us has a low rate from the user’s feedback, and the failure is usually solved after we have re-installed it In fact, the first thing to check is when there is a failure is whether the installation is strictly in accordance with the operating instructions if there is no problem in the inspection instrument internal problems

- Fault analysis of Vortex flow meter during installation

In the inspection of Vortex flow meter installation problems, mainly from the instrument installation position, wiring, flow range, pipeline vibration and interference, and so on.

- There is a flow of fluid in the pipe after electrification, but no signal output

Processing Method

First, check whether the instrument wiring is normal, the signal line is broken phenomenon, check whether the direction of the surface Arrow flow in line with the direction of the fluid and check whether the instrument is in the lower limit of the flow range

- There is no fluid flow in the pipe after electrification, but there is the signal output

Processing Method

Check the instrument grounding is normal, whether the pipeline is subjected to strong vibration, check the Vortex Street flowmeter surrounding the environment whether there is strong electromagnetic interference

- The fluid in the pipe meets the flow requirement, but the signal output is unstable

Processing Method

Check if there is a strong vibration disturbance in the pipe, and check if the instrument grounding is normal

- Instrument Malfunction

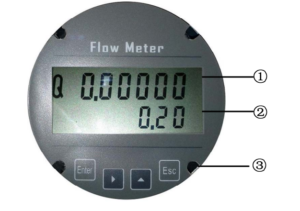

The faults of the Vortex flow meter are analyzed from the following aspects: whether the sensor probe is invalid, whether the amplifier is out of order, whether the instrument is broken, whether the surface is leaking, etc.

- There is fluid flow in the pipe after electrification, but there is no signal output

Processing Method

Check whether the test amplifier and test components are damaged, the damage should be replaced or renewed in time

- There is no fluid flow in the pipe after electrification, but there is a signal output

Processing Method

Check if the sensitivity of the converter is reduced.

- Simple judging method of sensor probe failure

The insulation resistance of two signal wires is measured by the multimeter. When the temperature is higher than 200 °C, the insulation resistance should be higher than 10 M. When the temperature is below 200 °c, the insulation resistance should be greater than 2M. If the insulation resistance does not meet the requirements that the detection probe may be faulty, it is necessary to repair the Sensor

- A simple judgment method of detection amplifier

A simple method to detect the fault of the amplifier: Using a hand to detect the inductive signal at the input of the probe lead in the detection amplifier, we can roughly determine whether the fault is detected. If there is no signal reflection detection amplification

Summary: from the data we know from our factory, the failure rate of installation is quite high, so the installation instructions must be strictly installed when the instrument is installed And the instrument itself problems are mainly in the use of more than 5 years of users have more problems.