The thermal mass flowmeter is a precision instrument that is produced by the latest technology and technology. Improper installation and use can lead to abnormal and damage to the instrument and even the process control equipment. Engineers and technicians who install, set up, and connect the product must read this manual carefully before using the instrument.

measuring principle

The thermal gas mass flow meter is designed on the basis of thermal dispersion and adopts the method of constant differential temperature to measuring gas flow. It has the advantages of small size, easy installation, high reliability, and high accuracy, etc.

The meter contains two platinum resistance temperature sensors. The thermal principle operates by

monitoring the cooling effect of a gas stream as it passes over a heated sensor. Gas flowing through the sensing section passes over two sensors one of which is used conventionally as a temperature sensor, whilst the other is used as a heater. The temperature sensor monitors the actual process values whilst the heater is maintained at a constant differential temperature above this by varying the power consumed by the sensor. The greater the gas velocity, the greater the cooling effect and power required to maintain the differential temperature. The measured heater power is therefore a measure of the gas mass flow rate.

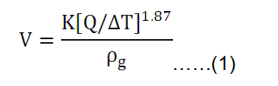

The format of gas velocity and power is shown as below:

Where: is the specific gravity of the medium

V is velocity

K is the balance coefficient

Q is heater power

Δ T is a differential temperature

The medium temperature range of the meter is -40℃~220℃.

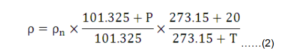

In format (1), the specific gravity of the medium is related to the density:

Where: is the medium density in working condition(kg/m3)

ρn is the medium density in standard condition, 101.325kPa, and 20℃ (kg/m3)

P is the pressure in working condition(kPa)

T is the temperature in working condition (℃)

In the formats (1) and (2), there is a certain functional relationship between the velocity and pressure in working condition, medium density, the temperature in working condition.

Due to the sensor temperature is always 30℃ higher than the medium temperature (environment temperature), and the meter adopts the method of constant differential temperature, therefore the meter does not need to do temperature and pressure compensation in principle.

For more details, pls check the details catalog.