Introduction

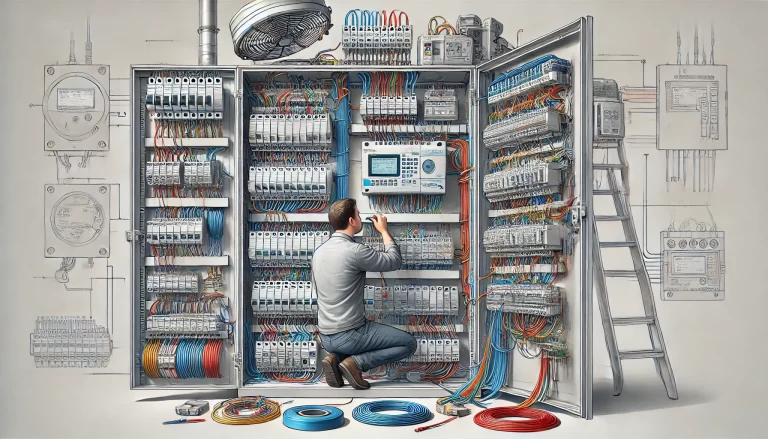

In the realm of industrial automation, the Programmable Logic Controller (PLC) serves as the “brain” behind countless systems and machinery. Yet, beneath the seemingly smooth operation of these control systems, engineers often encounter inexplicable failures—problems that appear and disappear without clear reason, almost as if some unseen force is at play.

One such persistent issue is contact bouncing, a phenomenon that leaves even seasoned engineers perplexed. Just when you think you’ve pinpointed the cause, the issue vanishes, only to reappear at the most inconvenient moment. Instead of attributing these occurrences to quantum mechanics, supernatural forces, or time-travel paradoxes, let’s dive into the real technical reasons behind these anomalies and explore effective solutions.

1. Signal Interference: The Invisible Culprit

1.1 The PLC and Signal Interference: Coincidence or Inevitable?

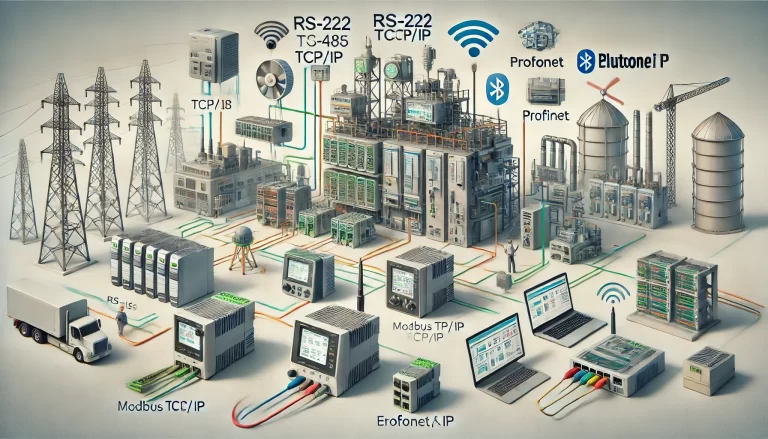

Signal interference is one of the most common yet unpredictable sources of PLC malfunctions. Industrial environments are filled with electrical equipment such as motors, variable frequency drives (VFDs), and high-power switching devices—all of which generate electromagnetic interference (EMI). When PLCs operate in such environments, their input/output signals can become unstable due to external noise.

Contact bouncing due to signal interference can manifest as erratic behavior: inputs flickering unexpectedly, outputs triggering without apparent cause, or even system crashes. Often, these disturbances lack a consistent pattern, leading to frustration and endless troubleshooting sessions.

1.2 The Uncertainty of Signal Behavior

While it’s tempting to liken signal interference to quantum mechanics, the reality is that these electrical disturbances follow well-established electromagnetic principles. However, much like the uncertainty principle in quantum physics—where observing a system can alter its state—measuring electrical signals with diagnostic tools can sometimes change the interference dynamics, making the problem even harder to pinpoint.

Factors that contribute to signal instability include:

Crosstalk between adjacent cables carrying high-frequency signals.

Improper shielding that allows external noise to penetrate signal lines.

Ground loops, which create unintended current paths that interfere with PLC performance.

1.3 Solutions: Shielding and Filtering

To mitigate signal interference, engineers should adopt the following best practices:

Use shielded cables and properly ground them at one end to prevent induced noise.

Employ ferrite beads or chokes to filter out high-frequency disturbances.

Isolate sensitive I/O modules from high-power components to reduce interference.

Implement differential signal transmission, which minimizes the impact of common-mode noise.

2. Poor Grounding: The “Supernatural” Effect

2.1 Grounding Issues: The Hidden Root Cause

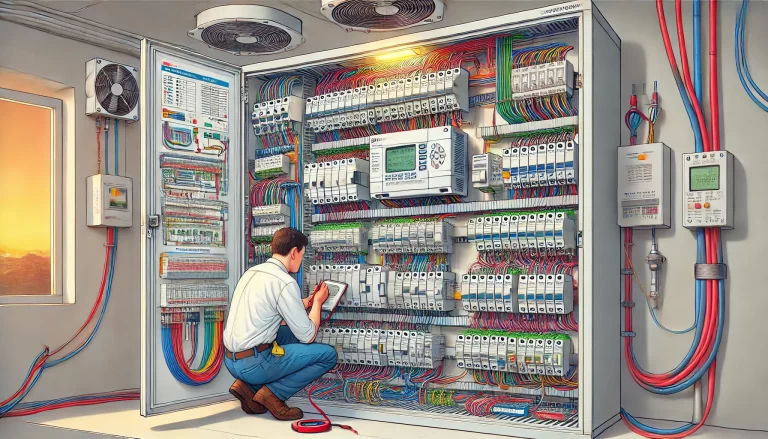

Proper grounding is fundamental to electrical system stability, yet improper grounding remains one of the leading causes of unexplained PLC failures. A poorly grounded PLC may experience:

Random I/O misfires

Fluctuating analog signals

Unstable communication between PLC modules

In some cases, engineers have observed that changing the grounding configuration mysteriously fixes the issue. This seemingly “supernatural” effect is actually due to variations in ground potential, which can alter the way electrical currents flow through a system.

2.2 The Science Behind Grounding Failures

Electrical grounding serves multiple purposes, including:

Protecting against voltage surges

Providing a reference point for stable voltage levels

Reducing electromagnetic noise

However, an improperly grounded system may result in ground loops—where multiple grounding points create unintended current paths. This can cause excessive noise, signal instability, and unpredictable PLC behavior.

2.3 Solutions: Optimizing the Grounding System

To prevent grounding-related issues:

Ensure a single-point ground for the PLC system to avoid ground loops.

Use low-resistance grounding cables to provide a stable reference potential.

Periodically test ground connections to identify degradation over time.

Separate signal grounding from power grounding to prevent interference.

3. Program “Runaways”: The Time-Traveling Glitch

3.1 Program Execution Errors: When Logic Goes Rogue

PLC programs follow predefined logic sequences, but sometimes these sequences don’t execute as expected. Symptoms of a “runaway” program include:

Looping indefinitely without expected outputs

Timers and counters behaving erratically

Failure to respond to external inputs

When engineers attempt to debug such issues, they often find that the problem disappears when stepping through the program manually, only to return unpredictably during live operation.

3.2 The Logic Behind “Runaway” Programs

A major cause of this issue is improperly structured conditions in ladder logic, such as:

Race conditions, where two instructions try to modify the same variable simultaneously.

Unintended feedback loops, which trap logic execution in an infinite cycle.

Memory corruption due to improper handling of registers.

Some engineers joke that their PLC program is “time-traveling”—working fine in one instance but malfunctioning in another. In reality, this is often due to overlooked conditions that only manifest under specific input scenarios.

3.3 Solutions: Strengthening Program Stability

To prevent unpredictable program behavior:

Use watchdog timers to detect and recover from program execution failures.

Implement structured debugging logs to track anomalies.

Limit nested conditions and optimize ladder logic to avoid excessive complexity.

Regularly update firmware to patch known software bugs.

Conclusion

While PLC failures can sometimes feel like unsolvable mysteries, each issue—whether it’s signal interference, grounding faults, or software glitches—has a scientific explanation. By systematically analyzing and addressing these problems, engineers can restore system stability and reliability.

As automation technology advances, PLCs will continue to improve in resilience and diagnostic capabilities, reducing the occurrence of these elusive failures. Until then, engineers must remain vigilant, patient, and methodical in troubleshooting, using both analytical skills and experience to unravel the mysteries of PLC behavior.

By understanding these principles and implementing best practices, we can finally put an end to the age-old question: “Why are my contacts bouncing again?”