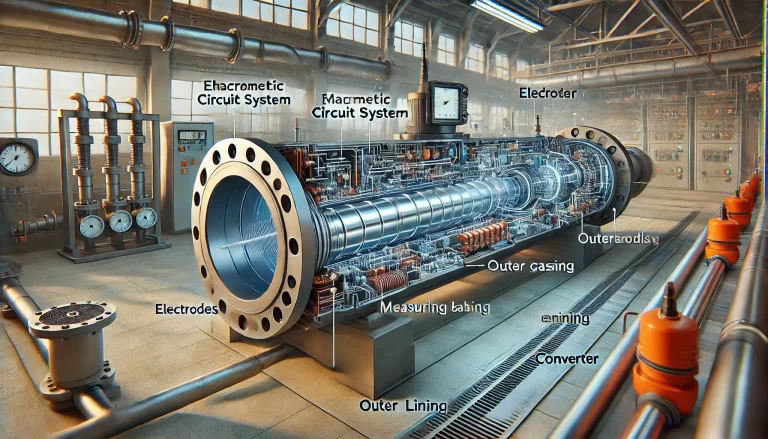

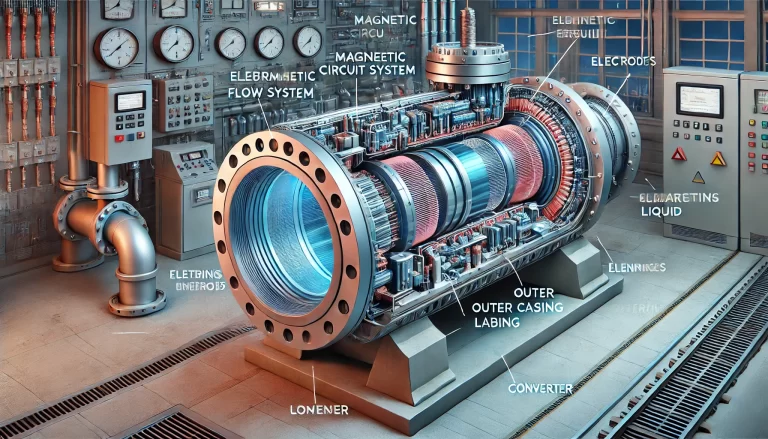

Electromagnetic flowmeters are widely used in industrial applications for measuring the flow rate of conductive liquids. Their structure is composed of several critical components, each with a unique function. This article provides an in-depth explanation of the components, their roles, and the key considerations for their design and application.

1. Magnetic Circuit System

The magnetic circuit system generates a uniform magnetic field, which can be either direct current (DC) or alternating current (AC). In most modern flowmeters, alternating magnetic fields are preferred, as DC systems can cause electrode polarization.

- DC Magnetic Fields: Typically created using permanent magnets. While these are simple in design and resistant to AC magnetic interference, they can lead to polarization of the electrolyte in the measured fluid, increasing internal resistance and affecting performance. Additionally, for large-diameter pipes, permanent magnets become impractical due to their size and weight.

- AC Magnetic Fields: Commonly generated using a 50Hz power supply. These systems avoid polarization issues and are more efficient for larger systems.

2. Measuring Tube

The measuring tube allows the conductive fluid to pass through while maintaining the integrity of the magnetic field.

- Material Selection: The tube must be made of non-magnetic, low-electrical-conductivity, and low-thermal-conductivity materials to ensure that magnetic flux lines are not disrupted. Common materials include non-magnetic stainless steel, fiberglass, high-strength plastics, and aluminum.

- Key Considerations: The tube must also exhibit sufficient mechanical strength to withstand fluid pressure and avoid deformation.

3. Electrodes

Electrodes are responsible for capturing the induced voltage, which is proportional to the fluid’s velocity.

- Material: Typically constructed from non-magnetic stainless steel, ensuring compatibility with the fluid and durability.

- Design: Electrodes are flush-mounted with the inner surface of the tube to prevent flow obstruction. Proper placement, often vertically oriented, prevents sediment accumulation and maintains measurement accuracy.

- Positioning: Electrodes should be installed in the pipe’s vertical axis to avoid the effects of sedimentation and air bubbles.

4. Outer Casing

The outer casing protects the internal components and isolates them from external magnetic interference.

- Material: Constructed from ferromagnetic materials to shield the excitation coil and ensure stable operation.

- Function: Provides mechanical protection and enhances the overall durability of the instrument.

5. Lining

The lining is a critical insulating layer inside the measuring tube, which comes into direct contact with the fluid.

- Purpose: Prevents the induced voltage from being short-circuited by the tube wall and enhances resistance to corrosion, wear, and high temperatures.

- Material Options: Common materials include polytetrafluoroethylene (PTFE), ceramic, and other corrosion-resistant, high-temperature, or abrasion-resistant materials.

- Selection Criteria: Depends on the chemical and physical properties of the measured fluid, such as corrosiveness, temperature, and abrasiveness.

6. Converter

The converter processes the weak voltage signals generated by the fluid’s movement and converts them into standard electrical signals for further analysis.

- Amplification: Enhances the weak induced signals captured by the electrodes to ensure accurate readings.

- Signal Conversion: Transforms the amplified signal into a standard format, such as 4-20 mA or digital signals, for integration with control systems.

- Noise Suppression: Includes filters to mitigate interference from electrical noise and ensure reliable measurement results.

Additional Considerations

When selecting or designing an electromagnetic flowmeter, it is important to consider the application environment and fluid characteristics. Factors such as temperature, pressure, and chemical composition will influence the choice of materials for the lining, electrodes, and measuring tube. The installation process should also ensure minimal interference from external magnetic fields and consistent fluid flow.

Application Scenarios

Electromagnetic flowmeters are ideal for applications involving:

- Highly Corrosive Fluids: The use of specialized linings such as PTFE ensures long-term durability.

- High-Accuracy Requirements: Their non-invasive nature ensures minimal disruption to the fluid flow and accurate readings.

- Large-Diameter Pipes: AC magnetic circuits enable effective performance even in large systems.

Summary

Understanding the structure and functions of each component of an electromagnetic flowmeter is essential for selecting the right model for a given application. By addressing the specific requirements of the fluid and installation environment, these instruments can provide reliable, accurate, and long-term performance in a variety of industrial contexts.