In flammable and explosive industrial environments, temperature monitoring is not just a routine operation but a cornerstone of safe production. Explosion-proof temperature sensors, as critical devices in this field, have become indispensable due to their unique working principles and broad applications. This article delves into the core principles, classifications, and importance of explosion-proof temperature sensors, exploring their vital role in modern industries.

Working Principles

Explosion-proof temperature sensors operate by converting temperature changes into usable output signals. These sensors fall into two primary categories: contact-based and non-contact-based sensors.

Contact-Based Sensors:

Resistance Temperature Detectors (RTDs): These sensors work on the principle that electrical resistance changes with temperature. RTDs are highly accurate and stable, making them suitable for precise measurements.

Thermocouples: Utilizing two different homogeneous conductors, thermocouples generate a voltage proportional to the temperature difference between their junctions. They are widely used due to their broad temperature range and durability.

Non-Contact-Based Sensors:

Infrared Temperature Sensors: These sensors calculate the temperature of a target surface by measuring emitted radiation. They are ideal for applications where direct contact is impractical or unsafe, such as in high-temperature or hazardous environments.

Types and Structures

Explosion-proof temperature sensors come in various types based on their working principles and structural characteristics. Common types include:

Thermistor Temperature Sensors: Known for their high sensitivity, thermistors are ideal for applications requiring rapid response times.

Thermocouple Temperature Sensors: These are rugged and reliable, suitable for extreme conditions.

Infrared Sensors: Offering non-contact measurement, these sensors are versatile for monitoring inaccessible or high-temperature areas.

The basic structure of these sensors typically comprises three components:

Temperature Element: A sensitive component that detects environmental temperature.

Protective Tube: Shields the temperature element from environmental damage, ensuring durability.

Connection Assembly: Transmits the temperature signals to external systems for monitoring or control.

Application Fields

Explosion-proof temperature sensors are widely used across various industries:

Chemical Plants: Essential in environments filled with flammable gases and vapors, ensuring operational safety.

Oil Fields and Petrochemical Industries: Provide accurate temperature data to prevent overheating and subsequent explosions.

Ammunition Depots and Fireworks Factories: Monitor storage conditions to prevent accidental ignitions.

Aerospace and Military: Support critical operations under extreme conditions, ensuring system stability.

These sensors also integrate seamlessly with display instruments, recording devices, and computerized control systems, enabling real-time monitoring, adjustment, and control.

Importance and Benefits

The significance of explosion-proof temperature sensors cannot be overstated. In industries like chemical manufacturing, dust-handling facilities, and pipeline networks, abnormal temperatures could trigger devastating explosions. By providing precise and reliable temperature readings, these sensors effectively prevent such accidents, safeguarding lives and property.

Additionally, they enhance production efficiency and product quality by enabling accurate process control. For instance, in pharmaceutical manufacturing, maintaining precise temperatures ensures product consistency and safety.

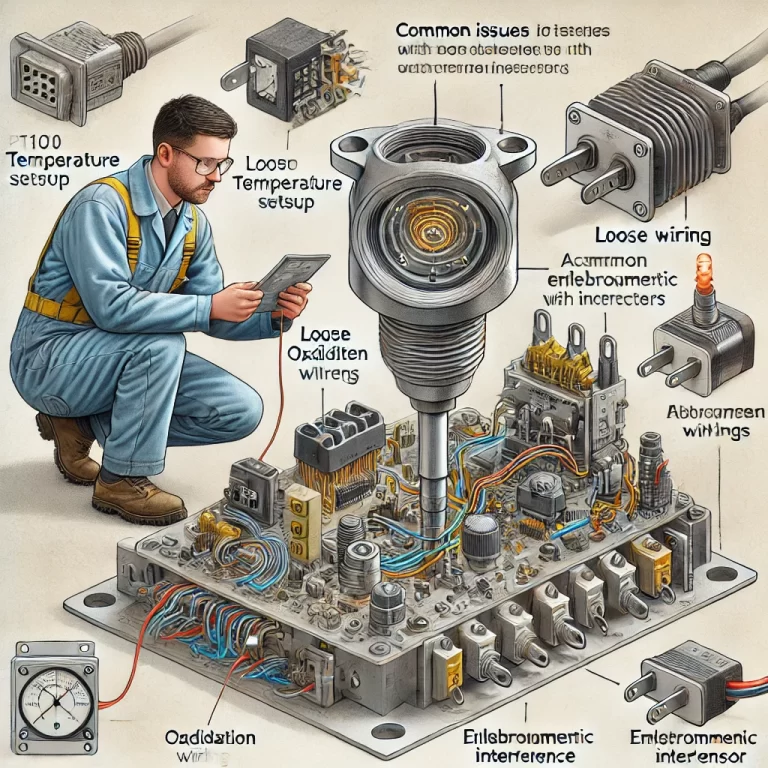

Common Issues and Solutions

Despite their advantages, explosion-proof temperature sensors can encounter issues such as:

Zero Drift: Gradual deviation in baseline measurements.

Sensitivity Loss: Reduced responsiveness due to component wear.

Non-Linearity: Measurement errors caused by aging components.

Overrange: Sensor malfunction due to exceeding temperature limits.

To mitigate these issues, regular calibration, cleaning, and maintenance are essential. Ensuring that the sensors operate within their specified ranges and are protected from environmental stressors is equally crucial.

Future Prospects

The evolution of explosion-proof temperature sensors aligns closely with technological advancements. Future developments are likely to focus on:

Smart Sensors: Integration with IoT platforms for remote monitoring and control, enabling predictive maintenance and real-time adjustments.

Advanced Materials: Employing new materials to enhance durability, sensitivity, and performance in extreme conditions.

Improved Explosion-Proof Design: Enhancing safety standards to meet increasingly stringent industrial regulations.

With these advancements, explosion-proof temperature sensors will not only improve safety and efficiency but also open new possibilities for automation and intelligent industrial systems.

Conclusion

Explosion-proof temperature sensors play an irreplaceable role in modern industrial environments. From their sophisticated working principles to their wide-ranging applications, these devices ensure safety, efficiency, and reliability in critical processes. As technology continues to advance, the future of explosion-proof temperature sensors promises even greater potential, driving innovation and ensuring safer industrial operations.