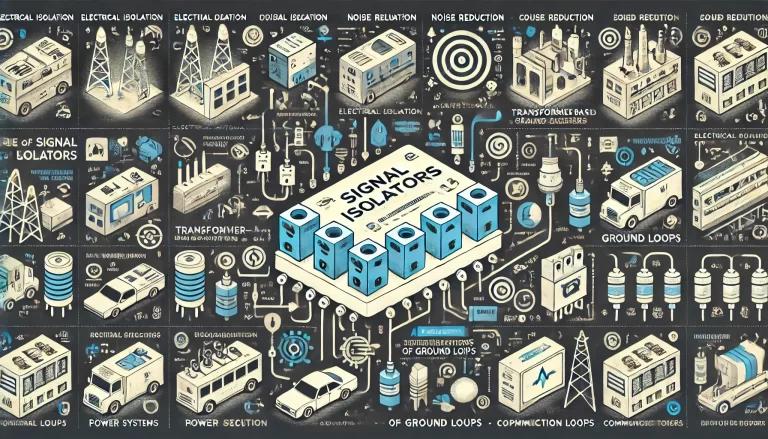

Signal isolators play a crucial role in modern electrical and electronic systems by ensuring the safe and accurate transmission of signals across different electrical environments. They are widely used in industries such as automation, healthcare, telecommunications, and power systems. This article provides an in-depth analysis of the functions, benefits, and applications of signal isolators.

What is a Signal Isolator?

A signal isolator is an electronic device designed to transmit an input signal from one circuit to another without establishing a direct electrical connection. Instead, it provides galvanic isolation between the input and output, ensuring that electrical noise, ground loops, and transient voltages do not interfere with signal integrity.

Key Functions of Signal Isolators

Electrical Isolation (Safety Protection)

Signal isolators provide galvanic isolation, which prevents high voltages from reaching sensitive equipment or personnel. This is especially critical in industrial settings where electrical hazards can pose significant risks.

Isolation prevents the propagation of electrical faults, protecting downstream equipment from damage caused by voltage surges or accidental short circuits.

Noise Reduction and Immunity

Electrical systems are often exposed to electromagnetic interference (EMI) and radio frequency interference (RFI). Signal isolators help mitigate these interferences by breaking the direct electrical path, which minimizes the potential for signal corruption.

They are particularly beneficial in environments with high electrical noise, such as manufacturing plants or power generation facilities.

Elimination of Ground Loops

When multiple devices share a common ground but are located at different potential levels, ground loops can occur, leading to unwanted currents that distort signals. Signal isolators effectively break these loops and ensure clean signal transmission.

This is crucial in distributed control systems (DCS) and programmable logic controllers (PLC) where multiple sensors and actuators are interconnected.

Signal Conversion and Adaptation

In many applications, signals need to be converted from one form to another, such as current-to-voltage (I/V conversion) or analog-to-digital conversion. Signal isolators facilitate such transformations while maintaining signal accuracy.

They can also match impedance levels between different devices, ensuring optimal performance.

Protection Against Transient Voltages

Industrial environments often experience voltage spikes due to lightning strikes, switching operations, or power surges. Signal isolators act as a protective barrier, safeguarding delicate instrumentation from transient overvoltage.

Signal Amplification and Conditioning

Some signal isolators incorporate amplification functions to boost weak signals for long-distance transmission.

They can also provide filtering to remove unwanted high-frequency noise and ensure stable, precise signal output.

Types of Signal Isolators

Signal isolators are classified based on the isolation technology they employ:

Optical Isolation:

Uses light-emitting diodes (LEDs) and photodetectors to transmit signals across an optical barrier.

Provides high isolation levels and immunity to electromagnetic interference.

Transformer-Based Isolation:

Utilizes electromagnetic induction to transfer signals through a magnetic core.

Commonly used in power applications where high-voltage isolation is required.

Capacitive Isolation:

Employs capacitive coupling to transfer signals while blocking DC components.

Suitable for high-speed data transmission applications.

Applications of Signal Isolators

Signal isolators are indispensable across various industries and applications, including:

Industrial Automation

Ensuring accurate signal transmission between sensors, actuators, and control systems in automated processes.

Used in PLC and DCS systems to isolate field instruments from control circuits.

Power Systems

Isolating monitoring equipment from high-voltage electrical grids to prevent damage and ensure personnel safety.

Applied in substation automation and power distribution monitoring.

Medical Equipment

Protecting sensitive diagnostic and monitoring devices from electrical noise and transient voltages.

Ensuring patient safety by isolating medical instruments from power supply fluctuations.

Telecommunications

Reducing signal degradation over long distances in communication networks.

Providing isolation to prevent interference between interconnected devices.

Test and Measurement Equipment

Ensuring accurate data acquisition by isolating sensors from measuring instruments.

Widely used in laboratory and field-testing environments.

Benefits of Using Signal Isolators

Enhanced Safety: Protects personnel and equipment from electrical hazards.

Improved Signal Integrity: Ensures accurate and noise-free signal transmission.

Increased System Reliability: Prevents damage due to electrical surges and transients.

Flexibility: Enables seamless integration of different systems and signal types.

Cost Savings: Reduces maintenance costs by preventing equipment failures caused by electrical interference.

Conclusion

Signal isolators are vital components in modern electrical and automation systems. Their ability to provide electrical isolation, noise reduction, and protection makes them indispensable across various industries. As technology advances, the role of signal isolators will continue to expand, ensuring the safety, reliability, and efficiency of electrical systems.