The safety of food is a critical aspect of human health and a fundamental part of maintaining economic stability and social harmony. Ensuring food safety is a complex, systematic process involving every step from production to distribution and, ultimately, consumption. The use of sensors in food production has become an essential element for controlling safety and quality at each stage, allowing manufacturers to monitor critical parameters accurately and reliably.

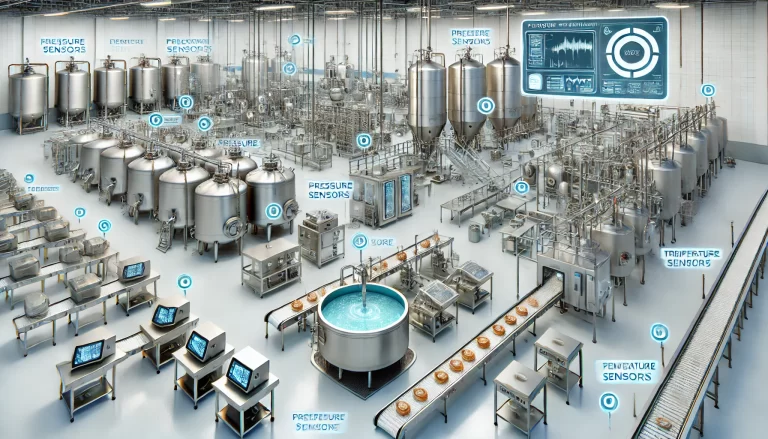

In modern automated food production, various sensors play integral roles by monitoring environmental and processing parameters, ensuring that food is produced at optimal quality under controlled conditions. Among the most commonly used types are pressure and temperature sensors, each with specific roles in maintaining product quality and safety.

Pressure Sensors

Pressure sensors are essential in maintaining the stability of production equipment by ensuring that containers and processing vessels operate within safe pressure ranges. By preventing excessive pressure, these sensors help avoid leaks, spills, or contamination, which could disrupt production or lead to safety hazards. For instance, in dairy production, pressure sensors can monitor and maintain the pressure during pasteurization, which is critical to eliminating harmful bacteria without compromising the product’s quality.Temperature Sensors

Temperature is a crucial factor in food safety, as even slight fluctuations can lead to contamination by harmful bacteria, affecting food quality and safety. Temperature sensors enable precise control of processing temperatures, particularly in stages like cooking, pasteurization, or fermentation, where even minor changes can impact the final product. In meat processing, for example, temperature sensors help ensure that cooking processes reach bacterial-killing temperatures without overheating, which would degrade texture and taste.Specialized Sensors for the Food and Beverage Industry

Flat membrane sensors, specifically designed for the food, beverage, and pharmaceutical industries, are distinguished by their hygienic properties and ease of cleaning. These sensors minimize contamination risks due to their sanitary design, which can be readily sterilized. In applications involving high temperatures, these sensors can be fitted with cooling devices to ensure that the temperature remains within the sensor’s operational limits, extending their lifespan and ensuring consistent readings.

The slogan “Integrity and Lawfulness Make Food Safety Better for Life” underscores the importance of stringent controls and monitoring in the food industry. The adoption of sensor technology not only contributes to safer food production but also enhances consumer trust by ensuring that the food reaching their tables has been monitored meticulously throughout the production process.

As sensor technology advances, it is expected that sensors will become even more precise, durable, and adaptable, allowing food manufacturers to achieve higher levels of safety and efficiency. With continued innovation, the food industry can look forward to a future where technology-driven safety measures become a standard, bringing peace of mind to consumers around the world.