Industrial instrumentation serves as the “eyes” and “nerves” of automation systems in chemical plants. From real-time monitoring and signal transmission to precision control, instruments are the backbone of safe, efficient, and intelligent manufacturing. This article explores five critical dimensions in which instrumentation plays a pivotal role—safety defense, process control, maintenance innovation, cost optimization, and decision support—alongside emerging technological trends that are reshaping the value of instrumentation.

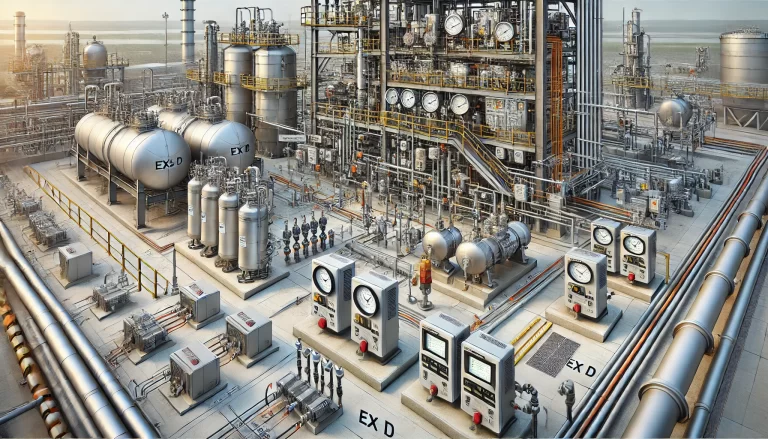

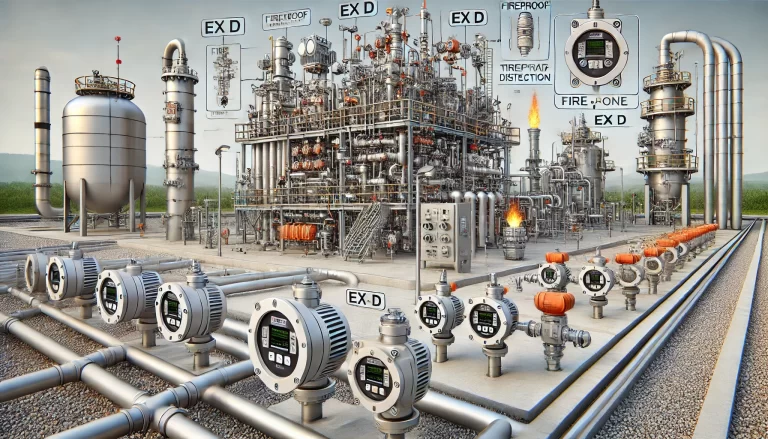

1. Safety Defense: From Passive Response to Proactive Protection

The inherent risks in chemical production (high temperature, high pressure, corrosive or flammable media) demand second-level precision in safety monitoring and response.

Real-Time Risk Detection

Instruments like pressure transmitters and temperature sensors continuously monitor variations in key process points. For example, a level switch triggers an interlock shutdown if a storage tank exceeds its safety threshold, preventing rupture or leaks.Smart Early-Warning Systems

Predictive instruments equipped with AI algorithms analyze historical data to detect abnormalities before failure. A vibration sensor monitoring pump frequencies can predict bearing wear trends, reducing failure rates by over 70% compared to reactive maintenance.Emergency Shutdown Integration

In Safety Instrumented Systems (SIS), instruments function as the front-line sensors that activate actuators like emergency shut-off valves and fire suppression systems. This enables a response time within 0.1 seconds during critical events like leaks or fires.

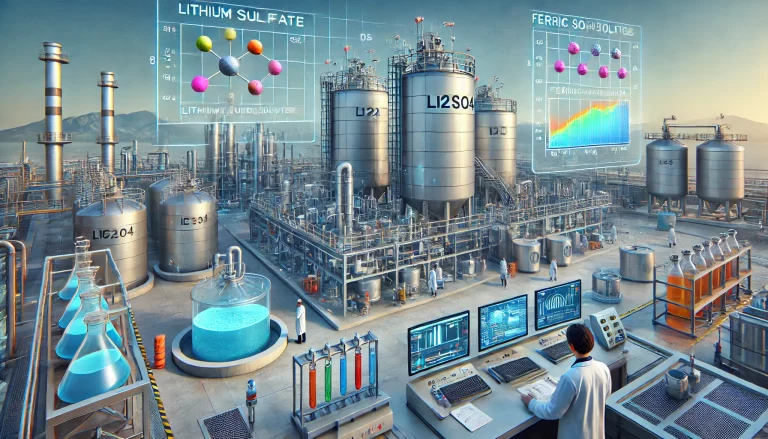

2. Process Control: From Operator Experience to Data-Driven Precision

Consistent product quality in chemical manufacturing depends on the stability of process parameters, and accurate instrumentation is the key to achieving micron- and percent-level control.

Precision at the Recipe Level

In polymerization, a Coriolis mass flowmeter with ±0.1% accuracy ensures the correct monomer feed ratio, avoiding human-induced batch defects and reducing raw material waste by up to 10%.Decoupling Complex Variables

For multivariable systems like distillation towers, a coordinated instrument network (temperature, pressure, flow) combined with advanced control strategies such as Model Predictive Control (MPC) can limit purity deviations to ±0.05%, outperforming conventional PID controls by over threefold.Reliable Performance in Extreme Environments

In highly corrosive applications like HF alkylation units, instruments made of materials such as tantalum and sapphire ensure long-term performance between –20°C and 200°C, avoiding frequent shutdowns due to instrument failure.

3. Maintenance Innovation: From Manual Inspections to Intelligent Lifecycle Management

Legacy maintenance models rely heavily on manual checks and periodic overhauls. Modern instrumentation systems are transforming operations toward digitization, prediction, and reduced manpower.

Full Lifecycle Digital Records

Platforms such as AMS Device Manager maintain calibration logs, diagnostics, and operational data, forming a “digital twin” archive for each instrument. A refinery that digitized over 5,000 devices reduced troubleshooting time from 4 hours to 1.5 and improved spare parts turnover by 40%.Predictive Maintenance Enabler

Online sensors collect vibration, temperature, and electrical data for AI-driven predictive analytics. For instance, bearing failures in pumps can be forecasted 7 days in advance, increasing planned maintenance to 70% and cutting unplanned downtime by 50%.Remote Maintenance Across Borders

Wireless HART instruments and cloud-based platforms allow engineers to configure, diagnose, and fine-tune devices remotely. A global chemical company cut instrument maintenance labor costs by 60% at its Southeast Asia sites and improved response times from 24 hours to real-time.

4. Cost Optimization: From Energy Waste to Operational Excellence

Instrumentation is not just a monitoring tool—it is a powerful lever for reducing cost and enhancing efficiency, particularly in energy-intensive sectors.

Transparent Energy Consumption

Instruments like steam flow meters and electromagnetic water meters allow real-time tracking of energy usage. One coal chemical plant identified abnormal compressor power usage and saved 20 million kWh annually (valued at $1.7 million) through control optimization.Material Balance and Leak Detection

Real-time flow measurements at input/output points support dynamic material accounting. A refinery used this data to detect a 0.3% raw material loss due to a hidden leak, recovering over 500 tons of crude oil annually—worth approximately $430,000.Targeted Maintenance Investment

Health diagnostics (e.g., signal drift detection) support condition-based maintenance instead of routine replacements. A chemical park using this strategy extended average repair intervals from 12 to 18 months and reduced spare part consumption by 35%, lowering maintenance costs by 25%.

5. Decision Support: From Intuition to Intelligent Manufacturing

In the era of Industry 4.0, instrumentation data forms the digital foundation for intelligent operations and strategic decision-making.

Control Room Command Center

DCS and SIS systems leverage real-time data to present a complete operational picture. Managers can monitor KPIs like load, consumption, and yield in real time. One petrochemical plant reduced dispatch decision times from 4 hours to 15 minutes, cutting order delivery cycles by 20%.Digital Process Optimization Lab

Historical data helps simulate past events for root cause analysis. A pesticide manufacturer analyzed subtle temperature fluctuations to discover agitator blade design flaws—after correction, product yield increased by 8%, generating over $1.5 million in added value.Compliance Audit Trail

Environmental and safety regulations demand verified data. Instrumentation data (e.g., VOC emissions, tank levels) serves as digital proof during inspections. A company using reliable VOC data passed environmental audits without shutdowns, avoiding losses of $280,000/day.

Future Trends: Smart and Connected Instrumentation

Emerging technologies like 5G, edge computing, and AI are redefining instrumentation as smart sensing terminals:

Wireless Instrument Expansion

Wireless HART/ISA100.11a devices reduce wiring costs and suit retrofits. For example, wireless temperature sensors on high-altitude pipelines enable stress monitoring without installation complexity.Embedded AI Algorithms

Instruments with machine learning capabilities can autonomously recognize abnormal patterns. In FCC units, smart sensors adjust regenerator setpoints based on historical profiles, reducing catalyst consumption by 5%.Digital Twin Integration

Instrument data powers virtual models to simulate faults and test repair strategies. A pump twin reduced repair planning time from 3 days to just 1 hour.

Conclusion: Instrumentation Is the Lifeline of Chemical Plants

Instrumentation is no longer limited to measurement. It enables the complete loop of data acquisition → transmission → analysis → application, forming the foundation for safety, quality control, operational efficiency, and informed management. In the dual context of carbon neutrality and intelligent manufacturing, strengthening the reliability and intelligence of instrumentation systems is essential to maintaining competitiveness.

Without precise and dependable instrumentation, there is no safe, efficient, or sustainable chemical production.