Balanced flow meters have emerged as a high-precision solution in fluid measurement, addressing limitations seen in traditional orifice plate flow meters. A key feature of balanced flow meters is their innovative multi-hole design, which significantly improves measurement accuracy, stability, and repeatability. This article explores the importance of hole design, typical configurations, and its impact on flow meter performance.

Challenges with Traditional Orifice Plate Flow Meters

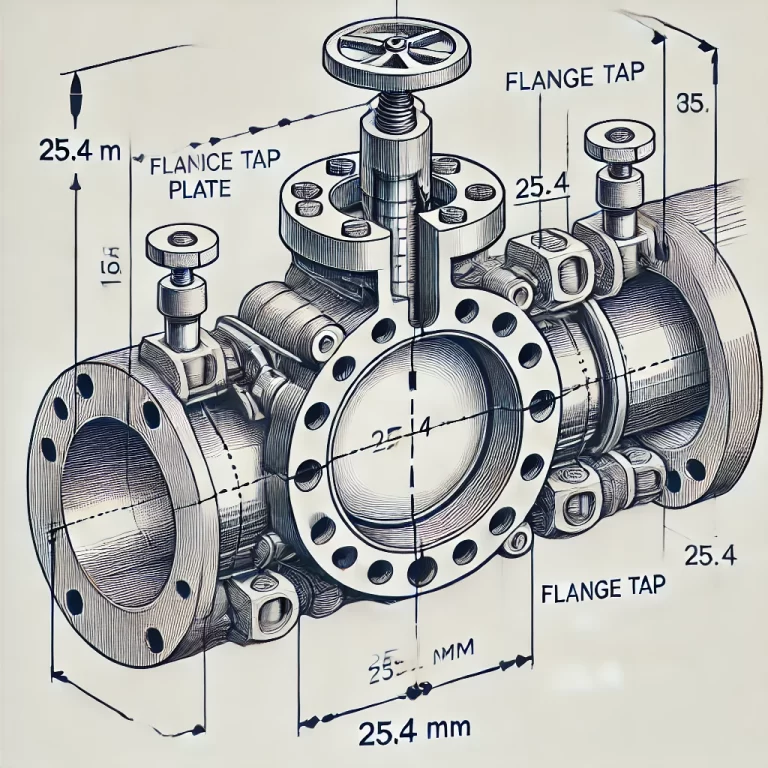

Traditional orifice plate flow meters rely on a single central hole to create a pressure drop for flow measurement. However, this design often leads to substantial turbulence, dead zones, and energy loss downstream. These issues reduce the linearity and repeatability of the measurements, especially in scenarios requiring high precision.

Advantages of Multi-Hole Design in Balanced Flow Meters

Balanced flow meters address these challenges by incorporating multiple symmetrically distributed holes, known as “function holes.” These holes are carefully sized and positioned to balance the fluid flow and minimize turbulence. Key benefits include:

Elimination of Dead Zones: By distributing the flow through multiple holes, balanced flow meters reduce the formation of dead zones that are typical in single-hole designs.

Reduction of Turbulence: Multi-hole structures ensure smoother fluid dynamics, which translates to less vibration and signal noise in the measurement system.

Higher Accuracy and Repeatability: Experimental calibration has shown that balanced flow meters achieve accuracy levels of 0.3% to 0.5%, with repeatability reaching ±0.1%.

Improved Long-Term Stability: Multiple holes distribute the mechanical wear and tear across the flow meter, preventing sharp edges from degrading over time and maintaining the flow coefficient

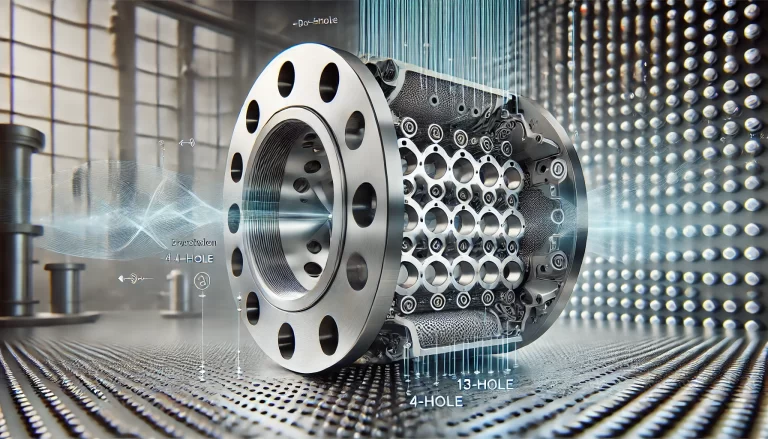

Typical Configurations of Hole Designs

Balanced flow meters offer a variety of designs tailored to specific measurement needs. The number of holes and their arrangement depend on fluid properties, operational requirements, and precision goals. Here are common examples:

4-Hole Design:

A simple configuration with evenly distributed holes, often used in basic flow measurement scenarios.

13-Hole Design:

A more sophisticated design featuring one central hole and 12 additional holes arranged in two concentric circles. For instance, holes might be distributed on outer radii of 16mm and 26mm.

A+K Balanced Flow Meters:

These designs feature 7 to 63 holes, depending on the application. The high number of holes ensures enhanced flow balancing, suitable for high-precision or complex fluid measurement.

1+6 Hole Configuration:

Common in wedge-shaped balanced flow meters, combining one central hole with six peripheral holes to optimize flow distribution.

Design Principles of Function Holes

The effectiveness of balanced flow meters lies in the precise design of their function holes:

Mathematical Modeling:

Function holes are calculated based on fluid dynamics equations, ensuring optimal size and placement to balance the flow.

Empirical Testing:

After initial calculations, designs undergo real-world calibration to validate performance and adjust parameters for specific fluid types.

Layered Arrangements:

Multi-layered hole structures are sometimes employed to further stabilize the flow and meet specific engineering requirements.

Applications and Use Cases

Balanced flow meters are suitable for a wide range of applications, including:

Trade Measurement: Their high accuracy and repeatability make them ideal for billing in oil, gas, and chemical industries.

Process Control: Stable and precise flow measurement ensures optimal process efficiency in manufacturing and power generation.

Research and Development: Advanced designs like the 63-hole A+K model support high-precision experimental setups.

Conclusion

The innovative hole design in balanced flow meters represents a significant advancement in flow measurement technology. By replacing the single-hole approach with multi-hole configurations, these devices offer unparalleled precision, stability, and durability. Whether configured with 4, 13, or even 63 holes, the versatility of balanced flow meters ensures they meet diverse industrial needs while maintaining exceptional performance over time. For businesses seeking reliable and accurate flow measurement, balanced flow meters are a clear choice.