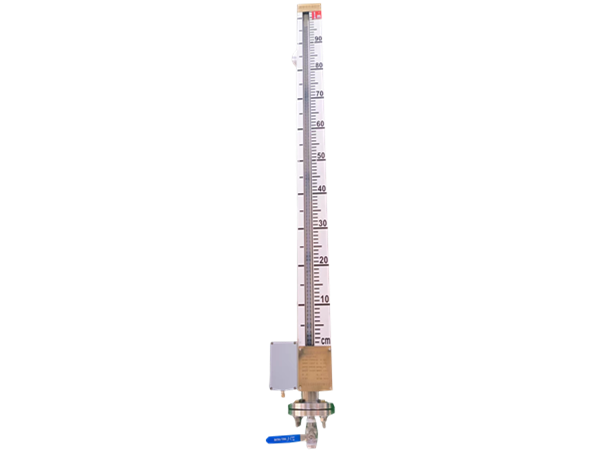

Magnetic level gauges are widely used in various industries for accurate and reliable liquid level measurement. A key component of these gauges is the magnetic float, which plays a critical role in detecting and displaying the liquid level within a tank or vessel. This article provides a detailed explanation of the function and working principle of the magnetic float in a magnetic level gauge.

Role of the Magnetic Float

The magnetic float is the heart of a magnetic level gauge, responsible for sensing the liquid level and transmitting this information to an external indicator. The float is typically a hollow, cylindrical, or spherical structure made of a material that ensures buoyancy while containing a permanent magnet inside.

The primary functions of the magnetic float are:

Floating on the Liquid Surface: The float is designed to have a density lower than the liquid in which it is immersed, allowing it to float and move freely with changes in liquid level.

Carrying a Permanent Magnet: The embedded permanent magnet interacts with the external indicator system, transmitting the liquid level information without requiring direct contact between the liquid and the indicator.

Providing Continuous Level Indication: As the liquid level changes, the float moves accordingly, ensuring a real-time and accurate display of the liquid level.

Working Principle of the Magnetic Float

The magnetic float in a magnetic level gauge operates based on the principles of buoyancy and magnetic coupling. Below is a step-by-step explanation of its working mechanism:

Buoyancy Effect:

The float is designed based on Archimedes’ principle, meaning it will remain at the interface of the liquid while rising and falling with the liquid level.

The selection of materials for the float is crucial to ensure proper buoyancy, preventing it from sinking or floating too high above the actual liquid level.

Magnetic Coupling Mechanism:

Inside the float, a permanent magnet generates a stable magnetic field.

As the float moves up and down due to liquid level fluctuations, the magnetic field moves correspondingly.

Outside the gauge, a magnetic display system (such as a series of bicolor magnetic flaps or a follower magnet) is installed to respond to the magnetic float’s movement.

Display Indication:

In a typical magnetic level gauge, the external display consists of a row of small magnetic flaps that are half-colored (e.g., red on one side and white on the other).

When the magnetic float moves up, the flaps in its range rotate 180 degrees, changing their color and indicating the new liquid level.

As the float descends, the flaps return to their original position, maintaining an accurate representation of the liquid level.

In some designs, a magnetic follower (a small external float that follows the internal magnetic float) moves along a transparent scale, directly displaying the liquid level.

Advantages of the Magnetic Float System

The magnetic float-based level measurement system offers several advantages over conventional level measurement techniques, including:

Non-Intrusive Measurement: Since the external indicator operates without direct contact with the liquid, the system is highly durable and resistant to corrosion or contamination.

No Power Requirement: Unlike electronic level sensors, magnetic level gauges do not require external power to function, making them ideal for hazardous or remote locations.

Reliable and Maintenance-Free: With no moving electrical components and a simple mechanical design, these systems require minimal maintenance and provide long-term reliability.

High Visibility and Accuracy: The bicolor flap display offers clear visibility from a distance, and the magnetic coupling ensures precise level measurement even under extreme conditions.

Conclusion

The magnetic float is a crucial component of a magnetic level gauge, enabling highly accurate, reliable, and maintenance-free liquid level measurement. Its operation is based on the principles of buoyancy and magnetic coupling, ensuring a continuous and precise indication of the liquid level. Due to its robust design and efficiency, the magnetic level gauge with a magnetic float is widely used in industries such as chemical processing, oil and gas, and water treatment. Understanding its role and working principle helps in selecting and maintaining the appropriate level measurement system for various industrial applications.