In many material production lines, the pre-expander is not the largest or most noticeable piece of equipment. However, experienced technicians often acknowledge that the stability of the pre-expansion stage significantly affects subsequent molding and product quality.

The primary function of a pre-expander (Pre-expander) is not simply to increase the size of the material but to adjust the raw material into a suitable particle state for molding through controlled heating, foaming, and subsequent drying and curing processes. These changes include density, pore structure, internal air pressure, and moisture content, all of which directly affect the strength, appearance, dimensional stability, and energy consumption of the final product.

Pre-expanders or similar equipment are commonly used in industries such as EPS/XPS foam materials, insulation boards, cushioning packaging, lightweight filling materials, certain food puffing processes, and chemical granulation. Whenever there is a need for particle pre-expansion or pre-treatment, pre-expanders are typically employed.

The Pre-expansion Process

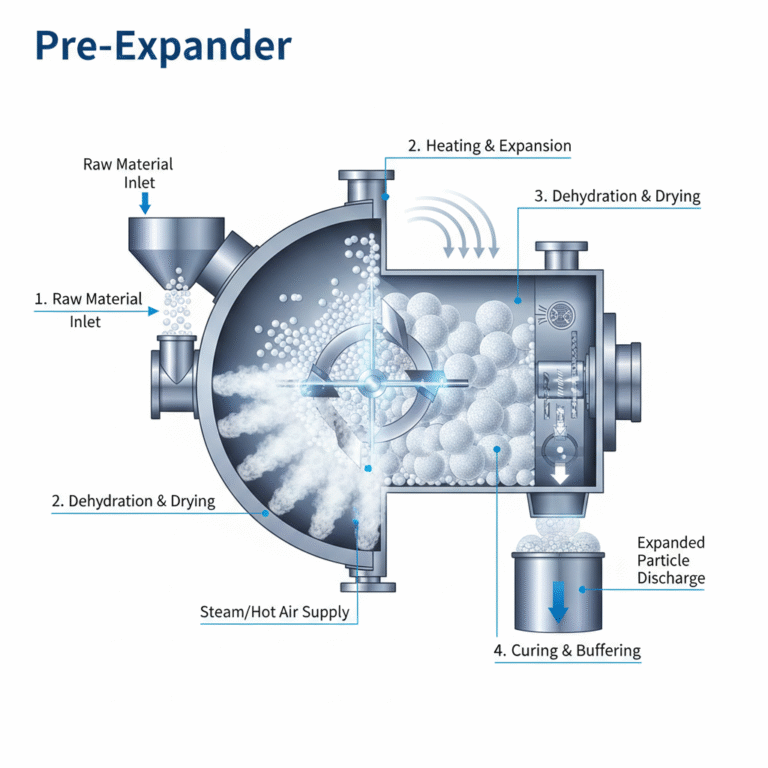

The typical pre-expansion process can be summarized in several steps:

Feeding

Heating and Expansion

Dehydration and Drying

Curing and Buffering

On the surface, these steps appear as a simple process flow, but in reality, they are aimed at altering the internal structure of the particles.

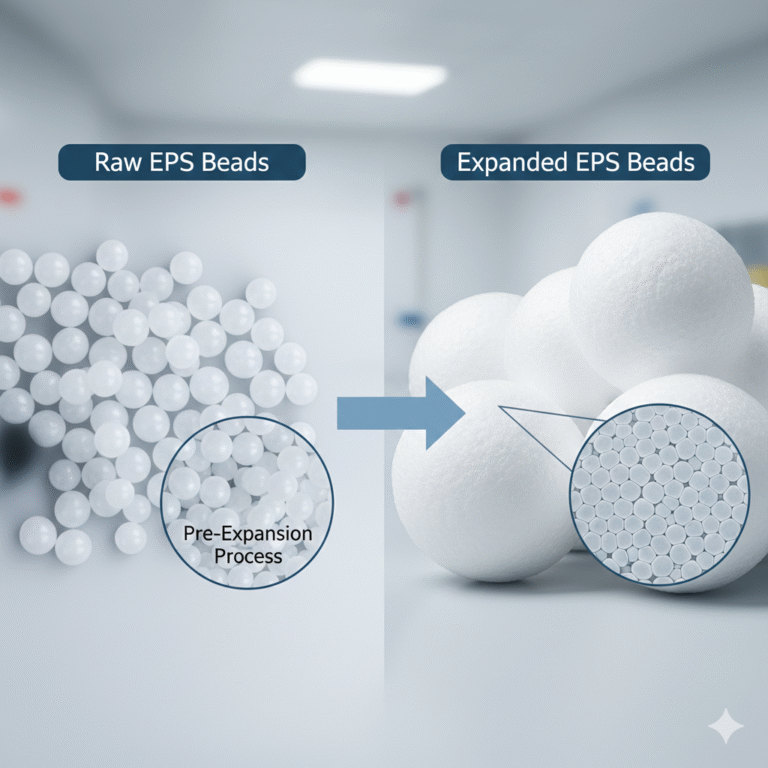

When raw material enters the pre-expansion chamber, it is heated via steam or hot air. In the case of EPS, the raw material contains a certain proportion of an expanding agent (such as pentane). After heating, the expanding agent vaporizes, creating gas pressure within the particles, which causes them to expand and form a more uniform closed-cell structure.

These closed micropores directly affect:

Thermal conductivity (insulation performance)

Cushioning and energy absorption performance

Localized stress distribution

Dimensional stability after molding

If the heating rate is too fast, the temperature is uneven, or steam pressure fluctuates significantly, it can result in localized over-expansion, insufficient foaming, or uneven pore structures, leading to issues like “big bubbles,” “collapsed bubbles,” or “uneven pore structures.” Such problems are often difficult to completely eliminate in subsequent molding processes.

To minimize these issues, pre-expanders are typically equipped with stirring or material tumbling mechanisms, which help ensure uniform heat distribution across the particles. This not only helps control particle size distribution but also stabilizes the density within the specified range.

Key Control Factors in the Pre-expansion Process

The most noticeable aspect in production is the pre-expansion density. However, from a process perspective, density is simply the result of multiple variables working together. These include:

Steam Pressure and Stability

The pressure level determines heating intensity and expansion extent. Pressure fluctuations directly affect density fluctuations. For EPS pre-expansion, medium to low-pressure steam is commonly used, with stability being more important than increasing pressure.Heating Time and Temperature Ramp

Insufficient heating time can lead to insufficient expansion and high density, while overly long heating times or rapid temperature increases can cause bubble rupture or over-foaming. Different raw material batches often require adjusted heating formulas.Stirring and Material Distribution Uniformity

Insufficient stirring leads to uneven heating and large particle size differences, while excessive stirring can cause particles to collide violently, which may lead to bubble rupture and fragmentation. During actual adjustment, the equipment structure, load amount, and steam flow direction need to be considered comprehensively.Raw Material Characteristics and Batch Variability

Variations in initial particle size, pre-existing gas content, expanding agent content, and surface coatings may cause issues if the process parameters are not adjusted accordingly.

In many on-site cases, “unstable density” is blamed on the equipment, but in fact, it is often caused by one or more of these variables being poorly controlled. From a technical perspective, a more reasonable approach is to break down the density issue and examine steam, time, stirring, and raw material characteristics one by one.

Drying and Curing in the Molding Process

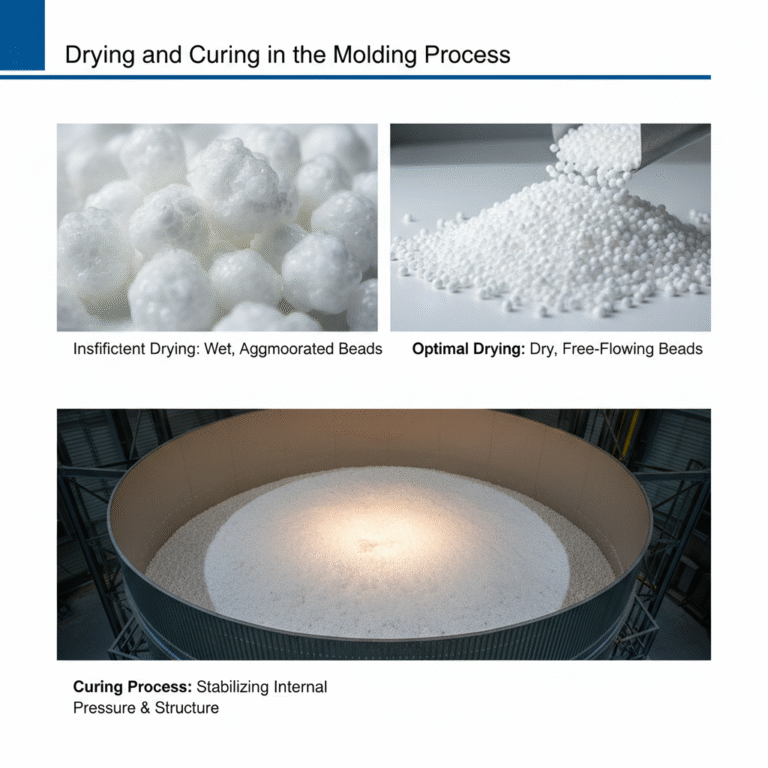

The drying and curing processes after pre-expansion are often overlooked but have a significant impact on product stability. Pre-expanded particles typically have high moisture content, and if dehydration or drying is insufficient or uneven, it can lead to:

Particle agglomeration and poor flowability

Poor ventilation during the curing process

Residue, cold joints, and pore issues in molding

Common configurations include centrifugal dehydration systems and hot air drying systems. Centrifugal systems remove surface free water, while drying further reduces surface and internal moisture, ensuring that the particle surface strength is appropriate for subsequent handling and storage. The goal here is not to achieve the “driest” state but to reach an optimal moisture content and particle condition within the allowed process range.

Curing is often the critical point for many quality issues. During curing, the particles are left to sit or undergo fluidized buffering, during which the internal air pressure gradually balances, and the closed-cell structure stabilizes. Inadequate curing can result in:

Indentations or edge collapse after molding

Significant shrinkage of products after cooling

Uneven surface textures or orange peel appearance

Extended molding cycles with poor venting

From a material behavior perspective, curing can be understood as the “buffering and redistribution” of internal stress and air pressure. From a process perspective, it is simply giving the pre-expanded particles enough time to stabilize. Therefore, curing time and airflow conditions should be based on factors such as density, particle size, environmental temperature and humidity, and product requirements, rather than using a fixed time value based purely on experience.

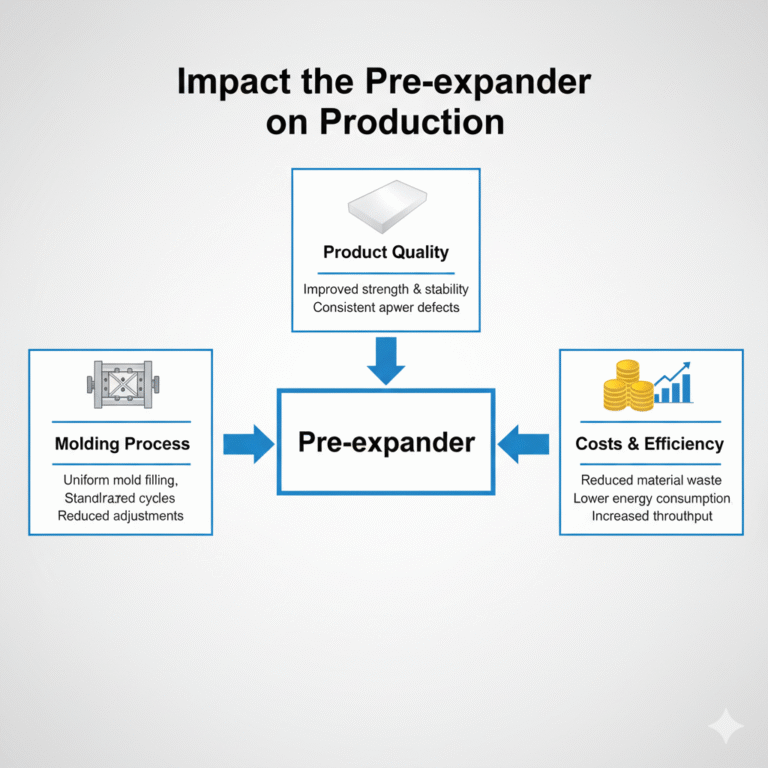

Impact of the Pre-expander on Production

From a production organization perspective, the pre-expander affects the entire production line in several ways:

Impact on the Molding Process

Stable density and particle size distribution lead to uniform filling of molds. With appropriate moisture content and sufficient curing, molding cycles become more standardized. When pre-expansion quality is stable, the need for frequent adjustments to molding parameters is minimized.Impact on Product Quality

Strength, dimensional stability, appearance, and surface texture are all influenced by pre-expansion parameters. Many “mold issues” are actually rooted in the pre-expansion and curing stages.Impact on Energy Consumption and Costs

Reasonable density control can reduce raw material usage while meeting performance requirements. High steam utilization efficiency and fewer re-adjustments can lower unit energy consumption. Stable pre-expansion reduces waste and rework, directly impacting overall manufacturing costs.Support for Data and Management

Some advanced pre-expanders are equipped with online density measurement, energy consumption statistics, and formula management functions. By recording the relationships between raw material batches, process parameters, and quality results, a process database suitable for the factory can be developed.

From a long-term perspective, treating the pre-expander as the starting point for quality data and process control is more valuable than viewing it merely as a foaming device.

Conclusion

From an equipment standpoint, the pre-expander is a key device responsible for heating, expansion, drying, and curing. From a system perspective, it is the first key node in the production process where raw materials undergo “structural and state reconstruction.”

For technicians, understanding the pre-expander does not require complex concepts. Instead, it is essential to clarify:

Which parameters are the key variables influencing the outcome

How these variables interact

How to troubleshoot and improve common issues during the pre-expansion process

Based on this understanding, technicians can develop tailored pre-expansion recipes and operating specifications suitable for their specific equipment, raw materials, and product requirements. This approach is far more reliable than simply relying on “experience-based adjustments.”