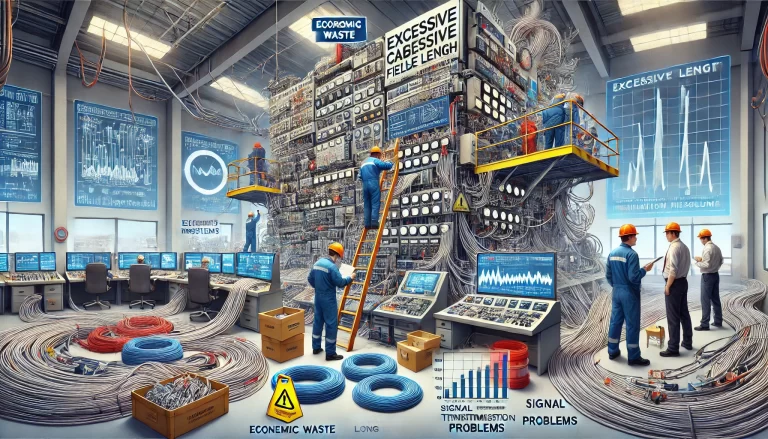

In instrumentation field installations, the excessive length of cables beyond the actual required usage can lead to multiple issues. This article explores the four primary risks: economic impact, signal transmission accuracy, construction efficiency, and operational maintenance.

1. Economic Impact

Excessive cable length directly contributes to increased procurement costs. With the current rise in non-ferrous metal prices, the cost of raw materials such as copper and aluminum continues to grow, placing a significant financial burden on projects. Over-specification and unnecessary length also result in wastage of valuable resources.

- Increased Material Costs: Longer cables require more raw materials, raising project expenses.

- Resource Inefficiency: Unused excess cable represents wasted investment that could have been allocated to other essential resources or equipment.

- Sustainability Concerns: Overuse of raw materials negatively impacts sustainability and increases the carbon footprint of the project.

Recommendation: Accurate pre-installation measurements and cable requirement assessments should be conducted to optimize cable lengths and reduce procurement costs.

2. Signal Transmission Accuracy

The accuracy and reliability of signal transmission are heavily influenced by cable length. Longer cables increase line capacitance and inductance, which in turn affect voltage drops and signal attenuation.

- Increased Line Impedance: Excessive length causes higher resistance and reactance, leading to voltage drops.

- Signal Attenuation: Prolonged cables weaken the strength of transmitted signals, causing potential misinterpretations or delays in instrumentation responses.

- Performance Limitations: For instruments requiring precise signal integrity over longer distances, excessive cable length can degrade performance significantly.

Real-World Impact Example: In scenarios where precise measurement devices like flow meters or temperature sensors are installed at remote locations, excessive cable length can compromise data accuracy, leading to incorrect readings and poor operational control.

Recommendation: Use cables optimized for the intended transmission distance and ensure compliance with signal integrity standards.

3. Construction Efficiency

From a construction perspective, overlong cables introduce unnecessary complexities and inefficiencies.

- Increased Labor Intensity: Workers must handle, lay, and secure extra cable length, which consumes additional time and effort.

- Equipment Strain: Cable management tools and installation devices may be overloaded or improperly utilized due to excess cable length.

- Project Delays: Construction schedules can be delayed as more time is required for installation and testing.

Recommendation: Implement standardized installation guidelines, including pre-assessment of cable path routes and cable cut plans, to minimize excessive deployment.

4. Operational Maintenance and Equipment Availability

Overly long cables pose challenges not only during installation but also throughout the operational lifecycle.

- Space Occupation: Excess cables occupy limited space in cable trays, conduits, and underground trenches, reducing available capacity for future installations.

- Maintenance Challenges: During troubleshooting and fault diagnostics, identifying and isolating problems in an unnecessarily long cable network becomes significantly harder.

- Replacement Difficulties: If a cable requires replacement, pulling out and reinstalling excessively long cables increases both cost and labor effort.

Recommendation: Use well-structured cable labeling, maintain updated diagrams, and ensure organized routing to streamline maintenance processes.

5. Best Practices for Avoiding Excessive Cable Length

To prevent the above issues, the following best practices should be adopted:

- Accurate Pre-Installation Planning: Conduct precise site surveys and layout designs.

- Adopt Standards and Guidelines: Follow international standards for cable length recommendations.

- Use Modular Cable Management Systems: Modular designs help adapt to future changes without unnecessary cable surplus.

- Regular Audits and Inspections: Periodically inspect cable installations to identify and rectify excessive lengths.

Conclusion

The risks associated with excessive cable lengths in instrumentation field installations are multifaceted, affecting economic efficiency, signal accuracy, construction workflows, and long-term operational maintenance. By addressing these issues through careful planning, adherence to standards, and regular reviews, projects can minimize unnecessary costs, improve system reliability, and enhance overall efficiency.

Investing time in precise cable length management not only saves money but also contributes to a sustainable and well-functioning infrastructure.