In fluid mechanics, the relationships between pipe diameter, flow rate, flow velocity, and pressure are interconnected through various principles and equations. These relationships are crucial in designing pipelines for various applications, such as water distribution, oil and gas transport, and HVAC systems. Understanding how changes in one parameter affect the others is essential for optimizing the performance and efficiency of fluid systems.

1. Flow Rate (Q)

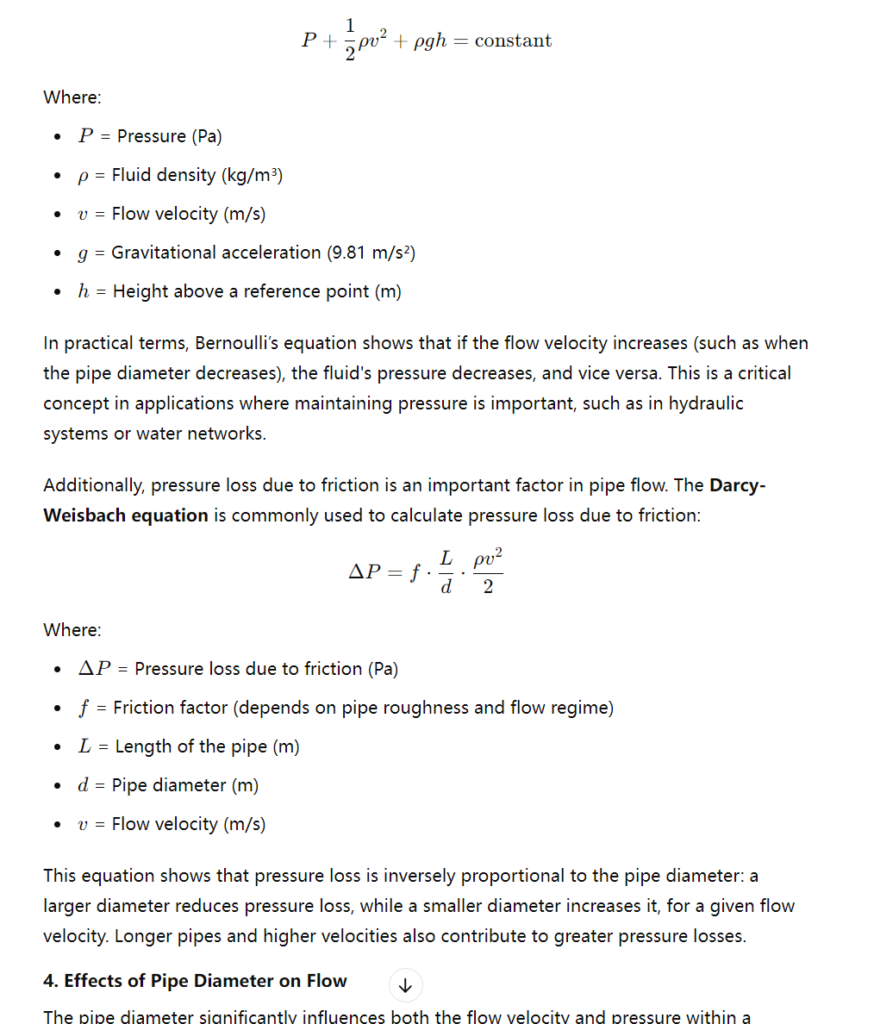

Flow rate represents the volume of fluid passing through a section of the pipe per unit of time. It is usually expressed in cubic meters per second (m³/s) or liters per second (L/s). Flow rate is a function of the cross-sectional area of the pipe and the flow velocity, as given by the equation:

Q=A×v

Where:

- Q = Flow rate (m³/s or L/s)

- A= Cross-sectional area of the pipe (m²)

- v = Flow velocity (m/s)

For a circular pipe, the cross-sectional area AAA is determined by the pipe’s diameter (ddd) using the formula:

A=πd2/4

This equation shows that the flow rate is proportional to both the square of the pipe diameter and the flow velocity. Therefore, for a given flow velocity, increasing the diameter of the pipe significantly increases the flow rate. Conversely, reducing the pipe diameter reduces the flow rate, assuming the flow velocity remains constant.

2. Flow Velocity (v)

Flow velocity represents the speed at which fluid moves through the pipe and is measured in meters per second (m/s). It can be calculated from the flow rate and the cross-sectional area of the pipe:

v=Q/A

This equation implies that the flow velocity is inversely proportional to the cross-sectional area. For a fixed flow rate, a smaller pipe diameter results in higher flow velocity, while a larger pipe diameter leads to lower flow velocity.

For example, in water distribution systems, high flow velocities may cause excessive friction losses, noise, and even pipe erosion over time. In contrast, low flow velocities may result in sedimentation and inadequate system performance.

3. Pressure (P)

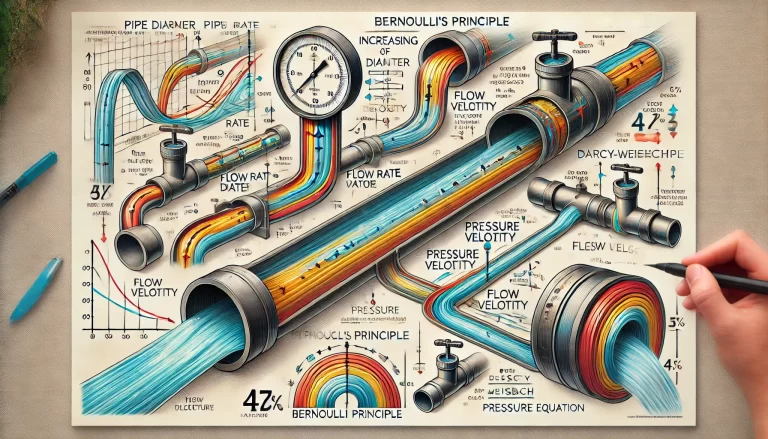

The relationship between pressure and flow velocity is described by Bernoulli’s principle, which states that in a streamline flow, the total energy (comprising pressure energy, kinetic energy due to velocity, and potential energy due to height) remains constant:

4. Effects of Pipe Diameter on Flow

The pipe diameter significantly influences both the flow velocity and pressure within a system. Let’s explore some practical scenarios:

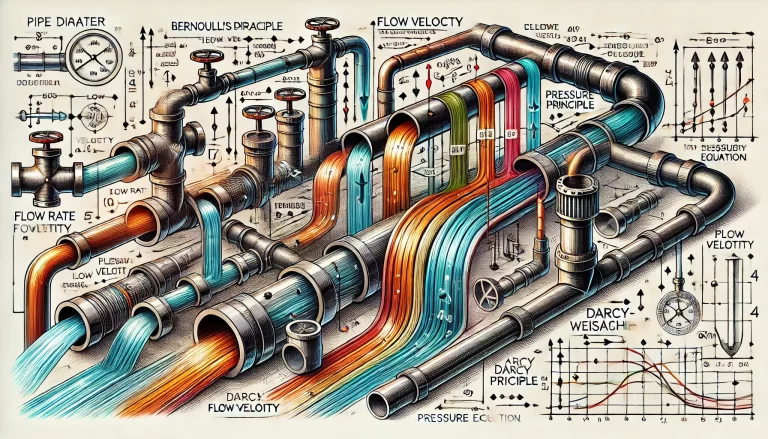

Increasing Pipe Diameter:

- Flow Velocity: For a constant flow rate, increasing the pipe diameter reduces the flow velocity. This can be beneficial in systems where minimizing friction losses is a priority.

- Pressure Loss: Larger diameters reduce pressure loss due to friction, as seen in the Darcy-Weisbach equation. This is important for long-distance pipelines where pressure losses must be minimized to maintain system efficiency.

- Energy Savings: Lower velocities in larger pipes lead to reduced energy consumption in pumping systems, making the design more energy-efficient.

Decreasing Pipe Diameter:

- Flow Velocity: Decreasing the pipe diameter increases the flow velocity for a given flow rate, potentially leading to turbulence, noise, and increased wear on the pipe.

- Pressure Loss: Smaller diameters increase pressure loss due to friction, which may require more energy to maintain the desired flow rate and pressure at the downstream end of the system.

- Potential Cavitation: In some high-velocity situations, a sharp reduction in pressure could cause cavitation, where vapor bubbles form and collapse, potentially damaging the pipe.

5. Practical Considerations

In designing fluid systems, engineers must carefully balance pipe diameter, flow rate, flow velocity, and pressure to achieve the desired performance. Key factors to consider include:

- System Efficiency: Minimizing pressure loss and maintaining adequate flow rates are crucial for system efficiency. Larger pipe diameters can help reduce friction losses, but they may also increase material costs.

- Operating Conditions: For systems operating at high flow velocities, the risk of pipe erosion or cavitation must be mitigated by adjusting pipe diameter or material.

- Pumping Requirements: Pressure losses increase the energy needed for pumping. Choosing the right pipe diameter can optimize pump operation and reduce long-term energy costs.

Conclusion

The relationship between pipe diameter, flow rate, flow velocity, and pressure is fundamental in fluid mechanics and plays a key role in designing effective fluid transport systems. By understanding how these variables interact, engineers can make informed decisions to balance efficiency, performance, and cost in applications ranging from industrial pipelines to household plumbing. Proper pipe sizing and an understanding of fluid dynamics ensure that systems operate safely, efficiently, and with minimal energy consumption.