Fundamental Formula:

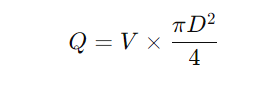

The flow rate (QQQ) is calculated using the formula:

Where:

- Q is the flow rate,

- V is the flow velocity,

- D is the internal diameter of the pipe.

This equation shows that if you know either the flow rate or the flow velocity, you can calculate the other parameter when the pipe diameter is given.

Can Flow Rate Be Calculated From Pressure?

Given a pipe diameter D and pressure P, can we determine the flow rate? The answer is no—not directly. To understand why, imagine there’s a valve at the end of the pipe. When the valve is closed, the pressure inside the pipe may be significant, yet the flow rate would be zero.

Therefore, the flow rate within the pipe is not directly determined by the internal pressure alone. Instead, it is the pressure gradient (the pressure drop along the pipe) that influences the flow rate. To calculate the flow velocity and rate, it is necessary to know the pipe’s length and the pressure difference between the two ends of the pipe.

Qualitative Analysis:

From a qualitative perspective, there is a direct proportional relationship between pressure and flow rate: as pressure increases, so does the flow rate. The flow rate is essentially the flow velocity multiplied by the cross-sectional area of the pipe. At any given cross-section of the pipe, the pressure is unidirectional, meaning the pressure only comes from one direction. If the exit is blocked (for example, when a valve is closed), the fluid inside the pipe is stationary. Once the exit opens, the flow velocity depends on the pressure within the pipe.

Quantitative Analysis:

For a more precise analysis, a hydraulic model can be used along with pressure gauges, flow meters, or other measurement tools to measure the volume of fluid passing through. For pressurized pipe flow, the flow rate can also be calculated using the following steps:

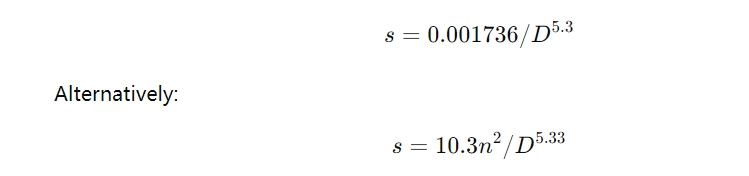

Calculate the specific resistance of the pipe (sss):

- For old cast iron or steel pipes, the Chezy formula can be used:

or refer to appropriate charts for resistance values.

2. Determine the pressure head difference (HHH): The pressure head difference is calculated as:

Conclusion:

In summary, while pressure and flow rate are related, you cannot simply derive the flow rate from pressure without knowing additional factors such as the pressure gradient, pipe length, and diameter. The flow velocity depends on the balance of these variables. Quantitative analysis requires specific data and precise measurement tools or calculations to obtain accurate results.