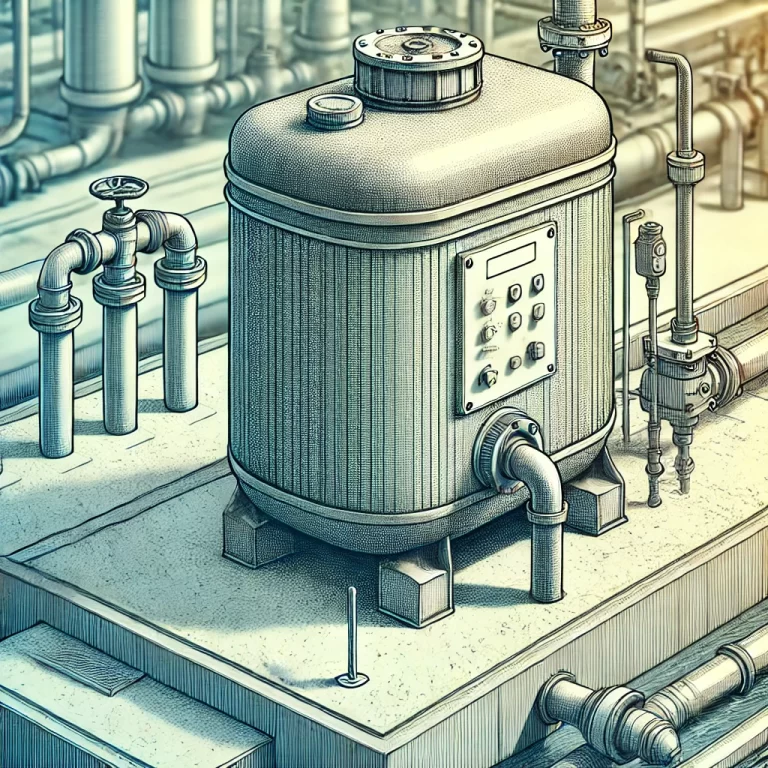

In industries such as chemical storage, food processing, and pharmaceutical manufacturing, real-time monitoring of the levels of substances in liquid containers is crucial for ensuring product quality and production safety. This article will introduce the application of radar level meters in measuring the well and dosing tanks and the benefits they bring.

A radar level meter is an instrument that uses electromagnetic waves (typically microwaves) to measure the height of liquid or solid materials in a container. It works by emitting microwave signals toward the surface of the medium and receiving the reflected signals. By calculating the time difference between the transmitted and reflected waves, the distance to the material surface is determined, providing an accurate measurement of the level. Compared to traditional mechanical or capacitive level sensors, radar level meters offer advantages such as being unaffected by the properties of the medium, non-contact measurement, high precision, and strong reliability.

So why choose to use a radar level meter in a dosing well? This is mainly due to its outstanding performance characteristics, including but not limited to high-precision measurement, strong environmental adaptability, ease of maintenance, and high safety. Dosing wells are often filled with various chemical reagents and pharmaceuticals, which may be corrosive or harmful to humans. Using a radar level meter allows for measurements without direct contact with the liquid surface, greatly reducing the risk of operators being exposed to harmful chemicals. Moreover, since the radar level meter does not rely on changes in the medium’s density or conductivity, it can maintain stable measurement results even in complex environments.

In a specific application scenario, let’s assume a pharmaceutical factory needs to precisely control the liquid level in a reactor to ensure the correct proportions and efficiency of a chemical reaction. By installing a radar level meter, operators can monitor the liquid level in the reactor in real time from the control room and automatically adjust the feed rate or shut off valves based on the data, thus preventing overflows or under-supply. This not only improves production efficiency but also significantly enhances the safety of the production process.

In addition to these advantages, radar level meters also have remote monitoring capabilities. This means that managers can monitor multiple dosing wells simultaneously through a network connection, no matter where they are. This remote monitoring function is particularly important for large factories, as it helps managers stay informed about the operational status of various equipment and respond promptly to potential issues.

As an efficient and reliable measurement tool, the radar level meter provides tremendous value in key areas such as dosing wells. It not only improves the accuracy and efficiency of measurements but also enhances the safety and convenience of operations.