In the realm of chemical production, reactors are often the core equipment, pivotal for achieving efficient and safe chemical reactions. Understanding a reactor’s true nature requires an engineering perspective, as it is more than just a “heatable container”—it is a complex system that integrates thermodynamics, fluid mechanics, material science, and automation control.

1. The Essence of Reactors

In both exothermic and endothermic reactions, reactors play a critical dual role: managing reaction heat and controlling mass transfer efficiency. The stable operation of a reactor depends on a delicate balance of multiple variables such as temperature, pressure, stirring, and material flow.

From an engineering standpoint, a reactor is a multi-coupled nonlinear system, with key control objectives including:

Matching reaction rate with heat release rate

Balancing heat transfer between the jacket and the reactor

The influence of stirring flow patterns on the reaction rate constants

Safety controls (e.g., over-temperature, over-pressure, emergency cooling)

A skilled reactor designer is one who understands both heat calculation and equipment structure, as well as chemical kinetics and control strategies.

2. Material Selection for Reactors

When selecting materials, many focus solely on the “stainless steel” label and overlook the electrochemical compatibility between the chemical medium and the metal.

Here’s a quick guide on commonly used materials:

| Material | Characteristics | Suitable Environments |

|---|---|---|

| 304 Stainless Steel | Cost-effective, good weldability, but poor chloride resistance | Mild acid and alkali systems |

| 316L Stainless Steel | Excellent resistance to pitting corrosion | Chloride and salt solutions |

| Glass-lined Steel | Strong acid resistance, heat shock sensitive | Acidic reaction systems (non-high temperature exothermic) |

| Titanium, Hastelloy | Excellent corrosion and mechanical resistance | Strong oxidizing and high-chloride environments |

| PTFE Lining | High inertness, non-stick properties | HF, strong oxidizing agent systems |

Practical Advice:

For exothermic reactions (such as esterification or polymerization), a metal reactor with an external jacket is recommended to enhance heat transfer responsiveness.

Glass-lined reactors have a heating rate limit of ≤2°C/min to prevent thermal stress cracking.

For systems containing trace fluoride or chloride ions, consider using titanium or Hastelloy, rather than 304 stainless steel.

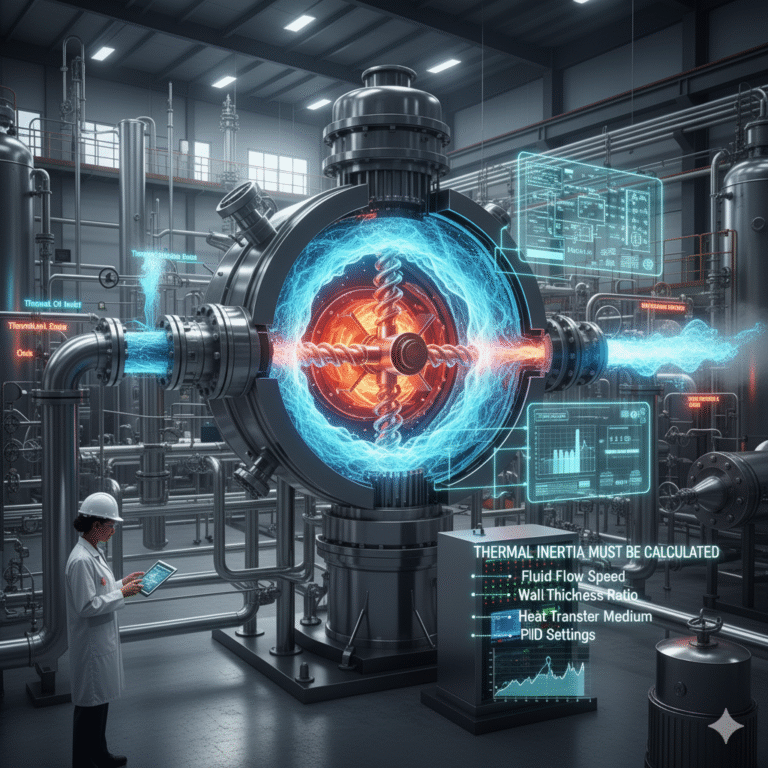

3. Jacket Design: Not All-Powerful, Thermal Inertia Must Be Calculated

While jackets are a popular design feature, their thermal inertia and response time are often underestimated.

Key design parameters to consider include:

Fluid flow speed in the jacket (recommended ≥1.5 m/s to avoid dead zones)

Wall thickness ratio of jacket to reactor (thinner walls conduct heat faster, but need to withstand fatigue)

Type of heat transfer medium (steam: quick response; thermal oil: broad range but high inertia)

Temperature control valve response and PID settings

The essence of temperature control is heat flow rate adjustment, not just a temperature switch. When heat release exceeds the heat removal rate, it causes thermal lag.

For highly exothermic reactions (e.g., medium-pressure hydrogenation or polymerization), consider using a dual heat exchange system with both internal coils and external jackets, and a DCS system to set thermal inertia compensation.

4. Stirring System: The Heart of Reactor Design

The stirring system is the soul of the reactor. Different types of stirrers create varying levels of turbulence, shear rates, and macroscopic circulation patterns.

| Type | Main Direction | Suitable Viscosity | Features | Practical Notes |

|---|---|---|---|---|

| Paddle-type | Radial flow | <500 mPa·s | Economical, suitable for low-viscosity systems | Use for dilute systems |

| Propeller-type | Axial flow | <1000 mPa·s | Strong turbulence, excellent heat transfer | Install baffles to reduce vortex |

| Turbine-type | Full mixing | <1500 mPa·s | Uniform mixing | Best for exothermic systems |

| Anchor-type | Shear weak | >5000 mPa·s | Wall scraping effect | Best for high-viscosity systems |

| Screw-type | Axial flow | >10000 mPa·s | Low speed, high efficiency | Requires baffles for circulation |

Engineer Advice:

For high-viscosity systems, use a dual stirrer system (anchor + propeller) to achieve wall scraping and circulation.

When both solid and liquid phases are present, ensure that the distance between the blade and the reactor bottom is 0.2-0.3 times the diameter.

5. Control Systems: Ensuring Stability

Modern reactors often come with DCS/PLC control systems, which can achieve closed-loop regulation of temperature, pressure, speed, and flow rate. However, process nonlinearity and delays often lead to control failure.

Practical tips:

Before each startup, conduct a cold-state simulation to test valve response and cooling priority logic.

For exothermic systems, implement segmented PID control.

Establish a reaction heat stability range to determine the safest operational window.

6. Maintenance and Lifespan Management

The longevity and maintenance quality of a reactor are closely tied. According to GB150-2011 Pressure Vessel standards, the following periodic maintenance is recommended:

Structural integrity check:

Conduct ultrasonic thickness measurements annually to prevent corrosion thinning.Heat transfer system maintenance:

Clean jackets and coils quarterly; sample thermal oil every 3000 operating hours to check acid value and flashpoint.Instrumentation calibration:

Calibrate temperature sensors biannually; replace solenoid valves with delays over 1 second.Safety accessories:

Annual inspection of pressure gauges and safety valves; cross-tighten reactor cover bolts according to torque requirements.

7. Conclusion: Reactors as a Reflection of Process Wisdom

The operation of a reactor is a reflection of the chemical reaction itself:

Temperature fluctuations reflect heat release rate; torque curves reveal viscosity changes; cooling flow changes correspond to the conversion stage.

A proficient engineer doesn’t just “watch instrument numbers”—they can “read the breath rhythm” of the reactor, interpreting its behavior to optimize reaction conditions.

8. Final Thoughts

Designing and operating a reactor is one of the most comprehensive tasks in chemical engineering. From heat transfer to process control, every detail can determine the success or failure of the product. Understanding it is not just a technical matter, but an engineering philosophy—balancing energy and reactions, integrating equipment and processes seamlessly.