In industries where hazardous materials are handled, safety is paramount. Ensuring that all equipment is properly connected and maintained is critical to preventing accidents and protecting workers. One such vital component in these environments is the explosion-proof flexible hose, commonly used to transport fluids and gases in various industrial settings.

Why Proper Connection Matters

Flexible hoses, often made from materials like stainless steel, are designed to be highly durable and resistant to harsh conditions. They are frequently employed in explosion-proof systems to safely conduct substances without compromising the integrity of the environment. However, ensuring the correct installation and sealing of these hoses is crucial to maintain their protective function.

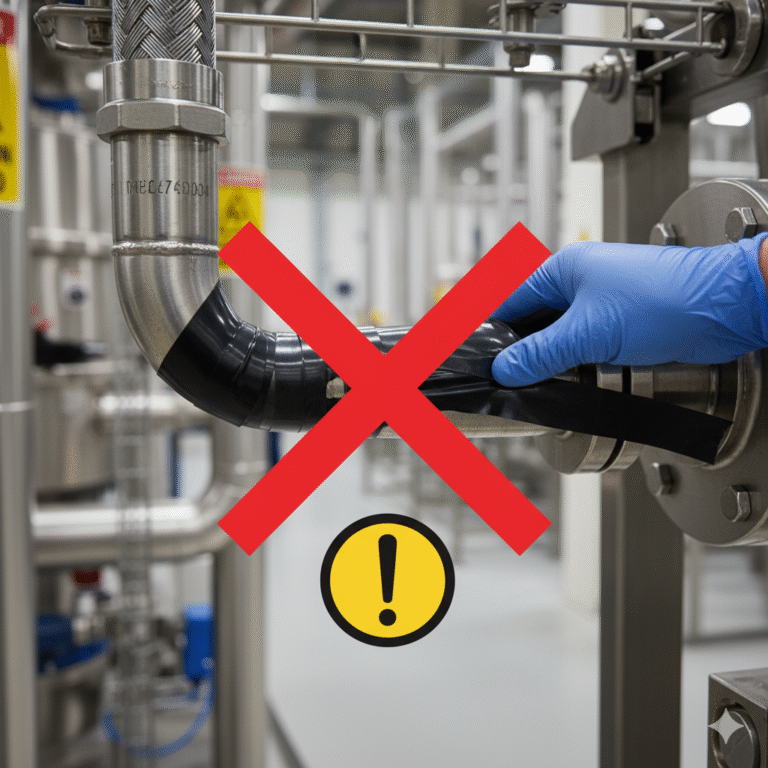

The Risk of Using Insulation Tape on Hose Connections

A common question arises when considering methods to seal threaded connections—can insulation tape be used to wrap around the threads of explosion-proof flexible hose connections? While it may seem like a simple solution, insulation tape is not appropriate for use in these critical connections.

Here’s why:

Electrical Continuity: Explosion-proof environments require continuous electrical paths to prevent the risk of sparks or electric arcs that could ignite flammable gases or liquids. Insulation tape can disrupt the electrical continuity between metal parts, leading to potential hazards.

Mechanical Strength: Insulation tape lacks the mechanical strength needed to maintain the integrity of the hose connection under pressure or mechanical stress. It could lead to loosening, leakage, or even the complete failure of the connection.

Fire and Explosion Risk: In explosion-proof applications, every component must meet strict standards to avoid igniting a flammable atmosphere. Using insulation tape in the hose connection could create an unintended insulation gap, which could cause electrical discharge, increasing the risk of fire or explosion.

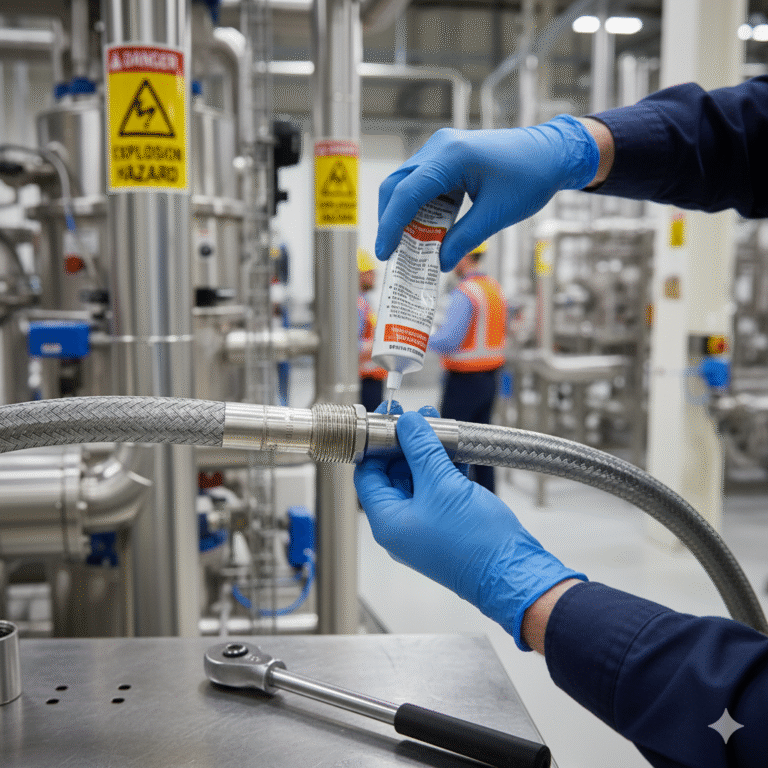

Recommended Practices for Safe Hose Connections

To ensure the highest safety standards, the following practices should be followed when installing and sealing explosion-proof flexible hose connections:

Use Approved Threaded Fittings: Explosion-proof hose connections should be made with standard, certified threaded fittings such as NPT (National Pipe Thread) or BSP (British Standard Pipe) threads. These fittings are designed to withstand mechanical stress and provide proper sealing without compromising the safety of the system.

Ensure Tight Sealing: Use appropriate sealing methods, such as thread sealant compounds, designed for explosive atmospheres. These sealants help create a leak-proof seal while maintaining electrical continuity and mechanical strength.

Follow Manufacturer’s Guidelines: Always consult and follow the manufacturer’s installation instructions. The proper torque specifications and sealing materials should be strictly adhered to for each component.

Periodic Inspections: Regularly inspect the hose connections for signs of wear, corrosion, or damage. Timely maintenance can prevent leaks and ensure that the connections continue to perform as intended.

Conclusion

Explosion-proof flexible hose connections are vital for ensuring the safety of industrial systems in hazardous environments. Proper installation and sealing are essential to maintaining their functionality and preventing risks. Insulation tape, while useful in some applications, is not suitable for sealing these critical connections. Always use certified threaded fittings and follow recommended safety practices to ensure the continued safe operation of your explosion-proof systems.