When we talk about instrumentation construction drawings, many people may think it’s simply a matter of reviewing blueprints. But what if I told you that a single oversight could paralyze an entire project, or even result in safety accidents? Would you still underestimate its importance?

Let me share a real-life example: In a large-scale chemical project, the construction team failed to conduct a thorough review of the instrumentation construction drawings. They proceeded with installation based on faulty drawings. During the trial operation phase, the instrument systems malfunctioned repeatedly. Key parameters like temperature and pressure were inaccurately monitored, which caused the production process to go out of control. The result? Not only did it lead to substantial financial losses, but it also posed significant risks to the surrounding environment and personnel safety. This highlights the disastrous consequences of neglecting the review of construction drawings.

Instrumentation construction drawing review is a vital step in ensuring safety. It helps identify potential issues early, prevents errors and rework during the construction process, and saves both time and costs. So, how should we conduct an effective review of these drawings? Let’s break it down.

1. Preparing for the Review: Laying the Groundwork

As the saying goes, “A bad workman blames his tools.” Similarly, a rushed or unorganized review will almost certainly miss critical issues. Before jumping into the actual drawing review, sufficient preparation is key. Think of it as laying a solid foundation before building a house.

Step 1: Collecting Relevant Materials

This is the first crucial step. Gather all necessary documents and specifications related to the instrumentation system. Ensure that the collected materials are both complete and accurate.

Step 2: Assemble the Review Team

Forming a dedicated review team is essential. Ensure the team consists of professionals with relevant backgrounds and experience in instrumentation, construction, and safety. Communication skills are equally important, as the team must collaborate effectively to spot issues from various angles.

Step 3: Develop a Review Plan

A well-drafted review plan will outline the scope of the review, key areas to focus on, and the timeline. This ensures the process is structured and that nothing is overlooked.

2. Seven Key Areas for Effective Review

Once the preparation is complete, it’s time to delve into the heart of the review process: analyzing the instrumentation construction drawings. This requires a keen eye for detail, as even the smallest oversight can lead to major problems. Here are seven key areas you must scrutinize during the review:

1. Equipment Selection: Getting It Right

The correct equipment selection is crucial, as it forms the foundation of the entire system. The specifications, model, and performance of the instrumentation must align with both the design specifications and the engineering requirements.

- Example: In high-temperature environments, thermocouples or resistance temperature detectors (RTDs) are ideal for temperature measurement. Meanwhile, if precise pressure measurements are needed in sensitive environments, pressure sensors should be selected.

The wrong equipment could compromise system accuracy and performance, ultimately affecting the entire process.

2. Layout and Positioning: Ensuring Ease of Operation and Maintenance

The layout of the instruments is vital not just for smooth operation, but also for the ease of maintenance. The positioning should be practical, allowing operators to read and adjust instruments easily, and technicians should have easy access to maintenance points.

- Key Points to Check:

- Are the instruments positioned for easy visibility and accessibility?

- Is there enough space for future maintenance and repair?

- Does the layout follow the process flow for optimal system efficiency?

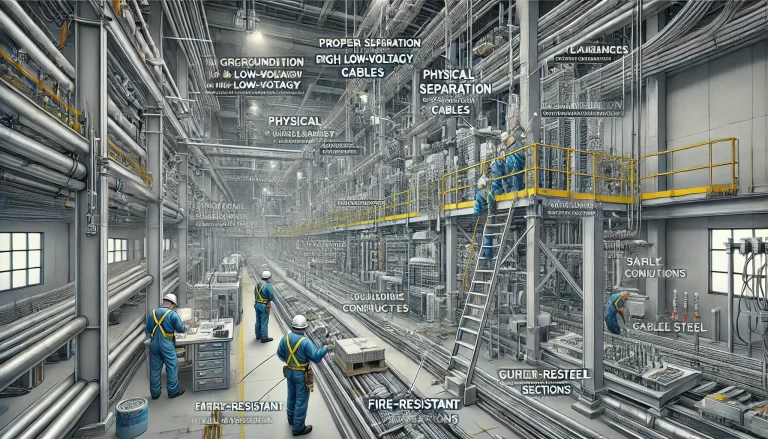

3. Piping and Cable Connections: Ensuring Safety and Stability

The piping and electrical connections are the lifeblood of the instrumentation system. How the pipes and cables are routed, connected, and secured will directly impact system reliability and safety.

Key Considerations:

- Are the piping connections and cable routes designed for minimal interference and signal loss?

- Have the connections been designed to avoid unnecessary bends and intersections?

- Are the pipes and cables secured properly to avoid damage due to vibration or external forces?

Potential Risks:

- Poorly routed cables can introduce signal interference or failure, compromising system performance.

- Crossed or collided pipes could cause leaks or even safety hazards.

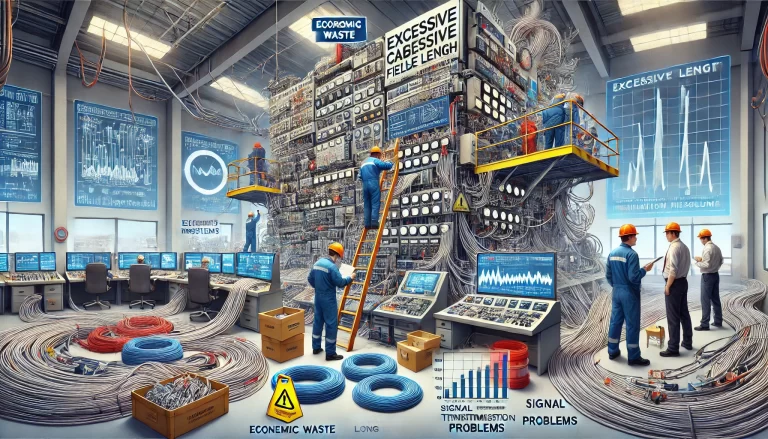

4. Signal Consistency: Ensuring Accurate Data Transmission

The signal system acts as the “nervous system” of the instrumentation. For the system to function properly, the transmission, conversion, and display of signals must be consistent and free from errors.

- What to Review:

- Are the signal transmissions stable and free from degradation or distortion?

- Is signal conversion done correctly, ensuring accurate data translation?

- Is the signal display clear and easy for operators to interpret?

5. Safety Measures: No Compromises

Safety should always be the top priority. During the review, make sure that appropriate safety features, such as explosion-proof, waterproof, and fireproof designs, are incorporated into the system.

- Key Areas to Check:

- Are all safety standards, including hazardous area classifications, met?

- Are appropriate safety barriers and fail-safes in place to prevent accidents?

6. Wiring and Connections: Properly Label and Secure

Electrical connections are a crucial aspect of instrumentation systems. Proper wiring, labeling, and securing of connections ensure system reliability and simplify troubleshooting during installation and maintenance.

Things to Verify:

- Are the wiring diagrams clear and accurate?

- Is the cable size and wire gauge correct?

- Are the connections securely fastened, with proper labeling for easy identification?

Common Mistakes to Avoid:

- Incorrect wiring or poor labeling can lead to operational failure or increase the risk of faults.

7. System Testing: Ensuring Quality Control

System testing and commissioning are critical to verifying that the instrumentation system works as intended. The review should ensure that the testing procedures cover all necessary aspects.

- Tests to Perform:

- Functionality Test: Does the system meet the design specifications?

- Performance Test: Is the system operating within the required accuracy and response time?

- Stability Test: Can the system operate reliably over time, even under varying conditions?

3. Common Pitfalls and Review Best Practices

To ensure that your review process is thorough, consider the following best practices:

- Maintain a Detailed Record: Document your findings carefully, noting down both positive results and issues to be addressed.

- Effective Communication: Constant collaboration with design, construction, and operational teams is essential. Regular feedback helps ensure everyone is aligned.

- Use Technology and Tools: Leverage digital tools and software to streamline the review process and identify potential issues faster.

Conclusion

Instrumentation construction drawing review is more than just a formal requirement—it’s a critical step to ensure safety, efficiency, and smooth project execution. By paying attention to key areas such as equipment selection, layout, wiring, and safety measures, you can avoid costly mistakes and mitigate risks before construction even begins.

If you found these tips useful, feel free to like, share, or bookmark this article! We also invite you to share your own experiences or tips in the comments—let’s continue learning and improving together.