In modern industrial plants, pressure piping systems are responsible for transporting high-temperature, high-pressure, flammable, toxic, or corrosive media. They connect production units, storage facilities, utility networks, and safety systems. In many cases, they function as the circulatory system of the entire process plant.

Because of the risks associated with these systems, installation supervision and inspection (commonly referred to as “installation inspection”) is not just a procedural requirement. It is a critical step that ensures the pipeline is safe, compliant, and ready for continuous operation.

A common question occasionally arises in project execution:

“If the materials and welding are done by certified contractors, can the pipeline be commissioned without installation inspection?”

The answer from both a legal and engineering perspective is:

No. Pressure piping must pass installation supervision and inspection before being put into service.

This requirement protects the safety of people, assets, and the long-term reliability of industrial operations.

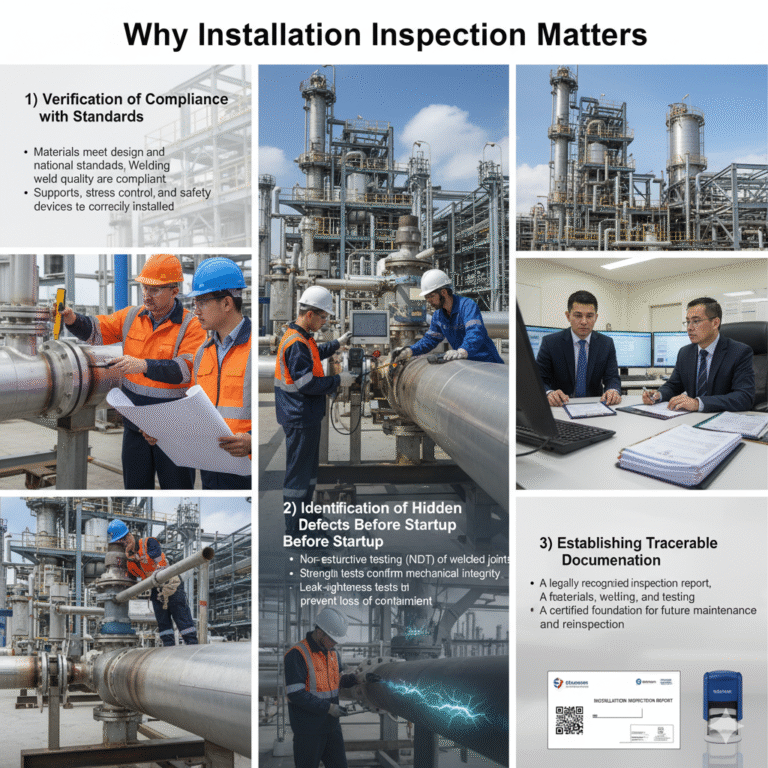

1. Why Installation Inspection Matters

Installation inspection provides three essential guarantees before a system is energized, pressurized, or connected to process media.

1) Verification of Compliance with Standards

Authorized inspection agencies verify whether:

Materials meet design and national standards

Welding procedures and weld quality are compliant

Supports, stress control, and safety devices are correctly installed

This prevents structural weakness from the beginning.

2) Identification of Hidden Defects Before Startup

Inspection includes:

Non-destructive testing (NDT) of welded joints

Strength tests to confirm mechanical integrity

Leak-tightness tests to prevent loss of containment

These steps detect defects that are invisible during construction, avoiding failures during operation.

3) Establishing Traceable Documentation

A completed installation inspection results in:

A legally recognized inspection report

A full technical record of materials, welding, and testing

A certified foundation for future maintenance and reinspection

This documentation becomes the “birth certificate” of the piping system.

2. Legal Requirements and Regulatory Obligations

Pressure piping is classified as special industrial equipment in many countries, and therefore falls under mandatory safety supervision.

In China, the Special Equipment Safety Law and Pressure Piping Supervision Inspection Rules clearly state:

Pressure piping must undergo installation inspection after installation, modification, or major repair.

Uninspected or unqualified piping may not be put into service.

Unauthorized operation constitutes illegal use and may result in fines, shutdown orders, and administrative liabilities.

Similar requirements exist internationally:

EU PED (Pressure Equipment Directive) requires conformity assessment and final inspection before CE marking.

ASME Boiler and Pressure Vessel Code (USA) requires involvement of an Authorized Inspector (AI) throughout manufacturing and installation.

Across global industrial practice, third-party, independent inspection is recognized as an essential safety safeguard.

3. Risks of Operating Without Installation Inspection

Commissioning a system without inspection introduces serious technical and operational risks:

| Risk Area | Potential Consequence |

|---|---|

| Weld defects not detected | Fatigue cracking, leakage, or sudden rupture |

| Material mismatch or wall thickness deviation | Accelerated corrosion, lower pressure tolerance |

| Improper supports and stress distribution | Piping movement, vibration, flange leakage |

| Unverified safety devices | Overpressure events and uncontrolled discharge |

A piping failure can lead to:

Production shutdown

Environmental releases

Personnel injuries or fatalities

Long-term damage to corporate reputation

In high-risk industries, a single failure can define an entire company’s future.

4. Business Impact and Liability Considerations

From an enterprise management perspective, bypassing installation inspection is also economically unsound.

Insurance claims may be denied if uninspected equipment is involved in an incident.

Accident investigations will identify lack of inspection as a direct cause.

Corrective re-inspection after commissioning requires draining, cleaning, isolating, scaffolding, and extended shutdown — costing far more than proper inspection during installation.

In short:

Inspection is an investment in long-term reliability and risk control.

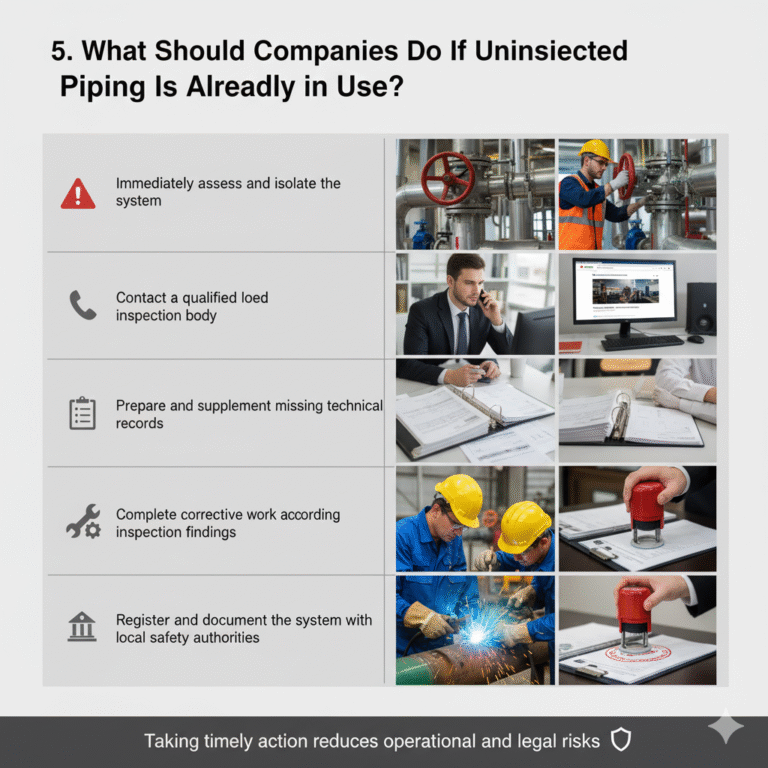

5. What Should Companies Do If Uninspected Piping Is Already in Use?

If a facility identifies systems that were commissioned before proper inspection:

Immediately assess and isolate the system.

Contact a qualified inspection body to request post-installation inspection.

Prepare and supplement missing technical records, including welding and material logs.

Complete corrective work according to inspection findings.

Register and document the system with local safety authorities once approved.

Taking timely action reduces operational and legal risks.

Conclusion

Installation supervision and inspection is not just a regulatory formality — it is a critical engineering assurance process that protects:

Personnel safety

Plant reliability

Corporate reputation

Long-term operational continuity

By ensuring compliance and performing inspection at the correct stage, companies build safer systems, reduce lifecycle maintenance costs, and achieve more stable and predictable plant operation.

Safety begins before startup. Reliability begins with compliance.