Introduction

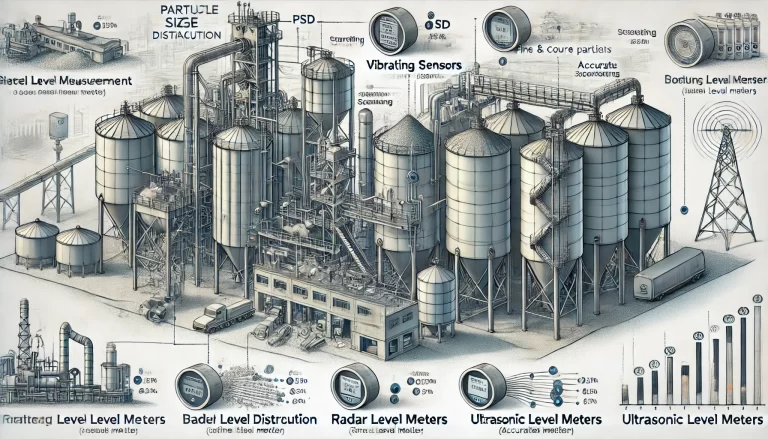

In industrial processes, level measurement is a critical step to ensure stable production and quality control. Level sensors monitor the storage states of materials in containers, silos, and tanks, providing essential data for process optimization and safety.

For solid granular materials, particularly powders or particles, particle size distribution significantly affects the precision, stability, and applicability of level measurement instruments. This article explores the concept of particle size distribution, its influence on common level measurement instruments (e.g., vibrating sensors, radar level meters, and ultrasonic level meters), and guidelines for selecting the appropriate sensors based on particle characteristics.

1. Overview of Particle Size Distribution

Particle size distribution (PSD) refers to the proportional distribution of different-sized particles within a material. PSD is often described using parameters such as D10, D50, and D90:

- D10: Indicates that 10% of particles are smaller than this diameter, representing coarser particles in the material.

- D50: Known as the median particle diameter, where 50% of particles are smaller than this size.

- D90: Shows that 90% of particles are smaller than this diameter, reflecting the material’s fineness.

The PSD not only impacts flowability, bulk density, and compaction properties but also influences the effectiveness of level measurement instruments. Understanding these characteristics is essential for accurate and reliable sensor performance.

2. Effects of Particle Size Distribution on Level Measurement Instruments

2.1 Vibrating Sensors

Vibrating sensors use a fork or rod that vibrates at a specific frequency. When material comes into contact with the sensor, the damping effect caused by the material changes the frequency, which is used to detect the level. However, PSD significantly impacts these instruments:

Large or Irregular Particles:

- Large or irregularly shaped particles (e.g., gravel or coarse ore) may accumulate around the vibrating probe, creating a “bridging” effect.

- This bridging can block vibrations and lead to false readings or measurement errors.

Fine Particles and Caking:

- Fine particles, such as powders or coal dust, tend to accumulate between vibrating forks, reducing the sensitivity of the frequency changes.

- This may impair detection accuracy, especially in materials prone to caking.

Solution: When using vibrating sensors, consider the material’s particle size and flowability. For challenging materials, sensors with anti-bridging designs or self-cleaning features should be prioritized.

2.2 Radar Level Meters

Radar level meters use electromagnetic waves (typically microwaves) to detect the material level by measuring the time taken for the signal to reflect back. PSD affects radar meters in several ways:

Large Particles:

- Large particles can cause scattering and refraction of radar waves, reducing signal strength and measurement accuracy.

Broad PSD:

- Materials with a wide PSD (e.g., a mixture of coarse and fine particles) can cause uneven reflection, leading to inconsistent readings.

Frequency Selection:

- Lower-frequency radar sensors (e.g., 6 GHz) perform better for coarse materials, while higher-frequency sensors (e.g., 26 GHz) are more suitable for fine powders or liquids.

Solution: Choose the radar frequency and configuration based on the material’s PSD and expected surface conditions.

2.3 Ultrasonic Level Meters

Ultrasonic level meters emit sound waves and measure the time taken for echoes to return. PSD influences these devices as follows:

Particle Size and Scattering:

- Large or irregular particles scatter sound waves, leading to signal attenuation or distortion, which reduces measurement reliability.

Surface Irregularities:

- A highly uneven surface, often found in granular materials, can cause the echo signal to become inconsistent, resulting in inaccurate readings.

Solution: Ultrasonic meters are best suited for fine-grained materials with smooth surfaces. For complex PSDs, consider radar meters instead.

3. Selecting Level Measurement Instruments Based on PSD

To ensure accurate level measurement, the PSD of the material must be a primary consideration when selecting an appropriate sensor:

Fine Particles:

- For materials with small particle sizes (low D10, high D90), such as powders or fine sand, radar meters with high-frequency signals or ultrasonic meters are recommended.

- These sensors can penetrate finer materials and handle smooth surfaces effectively.

Coarse Particles:

- For materials with large particle sizes (high D10, D50), such as ore or gravel, vibrating sensors may be preferable.

- Ensure the sensor design can handle bridging and minimize false alarms.

Mixed PSD:

- For materials with a broad PSD range, radar level meters or specially designed vibrating sensors with anti-bridging capabilities are ideal.

- These instruments provide better adaptability to mixed material conditions.

4. Enhancing Sensor Accuracy with Practical Strategies

To further improve sensor performance in real-world applications:

- Analyze Material Characteristics: Conduct detailed PSD analysis to understand the specific challenges posed by the material.

- Optimize Installation: Position sensors to minimize particle accumulation and bridging.

- Test in Operational Conditions: Perform field trials under actual conditions to verify sensor compatibility and adjust settings.

Conclusion

Particle size distribution plays a crucial role in the selection and performance of level measurement instruments. By understanding the PSD characteristics of materials, engineers can choose the most suitable sensors, ensuring accurate, reliable measurements and stable production processes. Incorporating PSD into the design and optimization of measurement systems is a key factor in achieving long-term operational success.