1. Introduction

With the rapid advancement of emerging technologies such as the Internet of Things (IoT), cloud computing, edge computing, digital twins, and artificial intelligence (AI), the petrochemical industry is undergoing a transformation from traditional automation to intelligent information systems. In response, China’s Ministry of Emergency Management issued the “Industrial Internet + Hazardous Chemical Safety Production” Pilot Program, promoting the deep integration of modern information technologies with hazardous chemical safety management.

Instrumentation and Control (I&C) Condition Monitoring Platforms are being implemented to support predictive maintenance and improve equipment reliability by shifting from reactive repair to proactive fault prevention. This paper explores how these platforms enhance plant safety, data-driven maintenance, and long-term digital evolution in the petrochemical sector.

2. Current Development of I&C Condition Monitoring Platforms

Refineries, as highly automated and complex process plants, operate under harsh conditions such as high temperature, high pressure, flammability, explosiveness, and corrosion. The reliability of instrumentation and control systems is thus critical.

To address this, Sinopec’s refining division established the I&C Condition Monitoring Platform Management Guidelines based on its Preventive Maintenance Strategy for Refining Enterprises. This standard covers architecture, data interfaces, equipment specifications, and functional applications, and aims to build centralized platforms across refinery control networks.

Each enterprise has since developed integrated monitoring and maintenance centers, adopting smart instruments, expanding predictive maintenance applications, and maximizing data collection across instrumentation systems.

3. Key Challenges in Platform Implementation

Despite the benefits, several barriers remain:

Data Silos: Vast amounts of smart device data remain uncollected or unanalyzed, forming isolated “data islands.”

Reactive Maintenance: Many systems still rely on alarms and post-failure repairs, lacking predictive capabilities.

Experience Dependency: Fault identification often depends on skilled personnel rather than objective analysis.

Resource Limitations: Inadequate data analysis capabilities and workforce expertise restrict early detection and timely response.

These issues hinder the shift toward centralized monitoring, predictive diagnostics, and proactive maintenance strategies.

4. Core Functionalities of the Platform

4.1 Basic Monitoring and Lifecycle Management

The platform captures equipment data across its lifecycle—from installation and operation to fault handling and decommissioning—enabling real-time tracking and closed-loop issue resolution.

4.2 Advanced Functional Modules

a. Valve Fault Diagnostics

The system evaluates valve health using multiple parameters such as setpoint, feedback signal, current, pressure, and control signal. Common diagnostics include:

Sticking valves

Actuation signal failures

IP converter faults

Airline issues

Stroke deviation

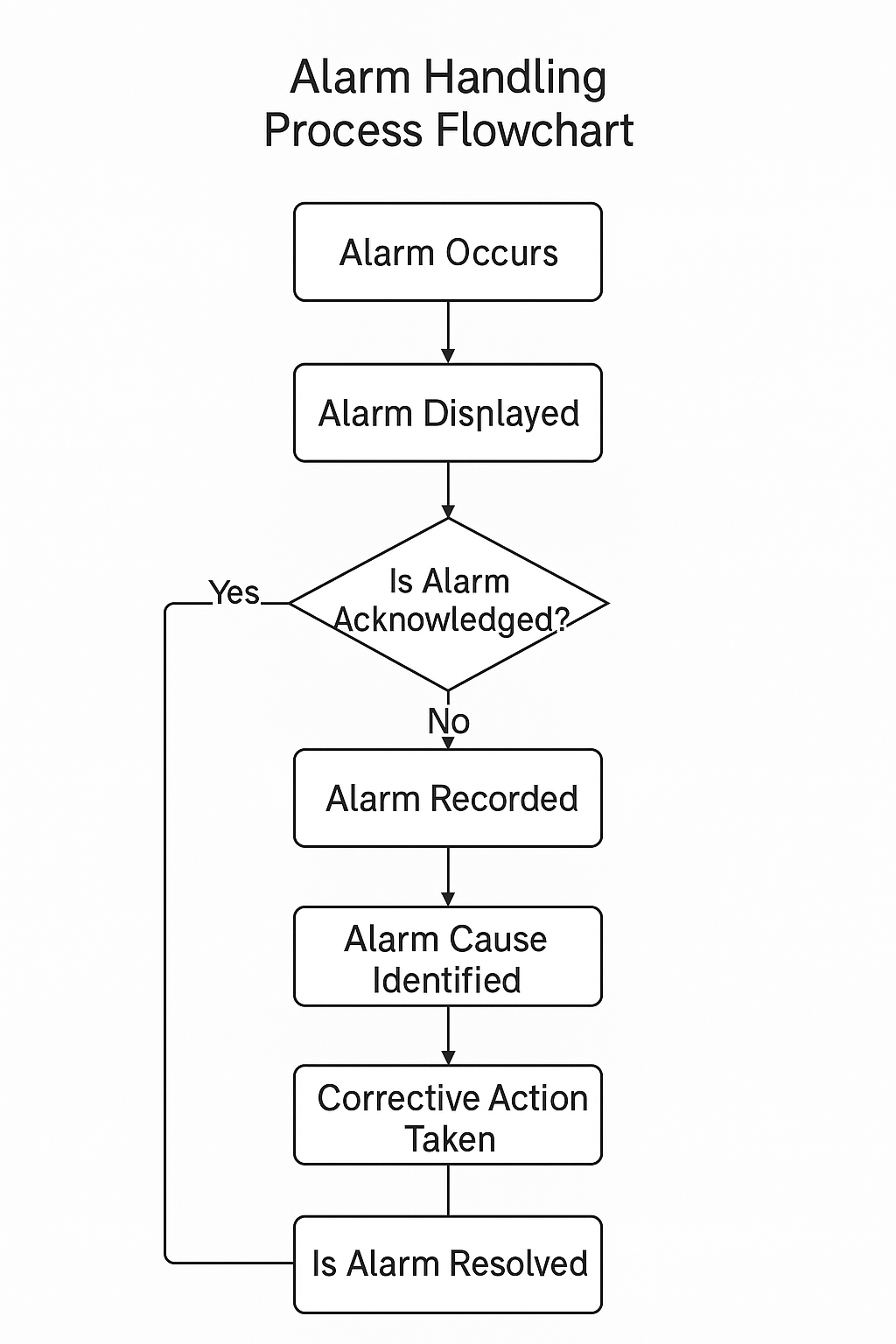

b. Alarm Database

Alarms are categorized by severity (Fault, Abnormal, Out-of-Range, Informational) per Sinopec’s defect management standards. The database enables:

Multi-sensory alerts (visual, audio, color-coded)

Alarm handling playbooks

Historical query by equipment model/manufacturer

Alarm accuracy improvement via field feedback

Equipment parameter parsing and manual digitization

c. Alarm Interpretation

Fault codes are translated into user-friendly descriptions and linked with troubleshooting recommendations via an expert knowledge base.

d. Condition Assessment

The platform conducts both online and offline diagnostics, comparing historical data, trend shifts, and peer benchmarks to identify and classify device deterioration.

5. Application Benefits

The platform brings measurable benefits to various stakeholders:

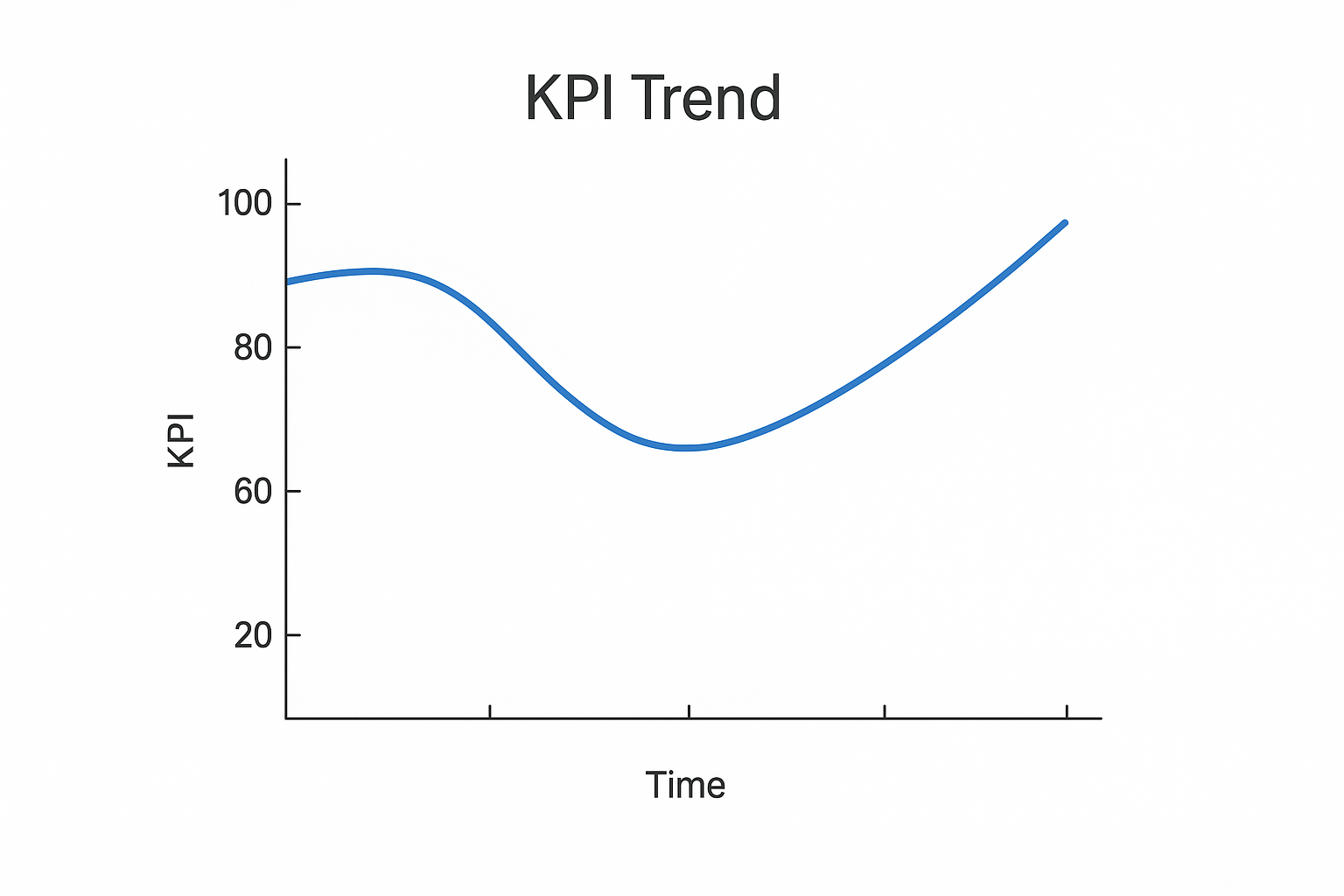

For Managers: Real-time transparency, performance tracking, and data-driven decision-making.

For Operators: Immediate alert reception, historical context access, and guided troubleshooting.

For Organizations: Enhanced KPI tracking, transition to predictive maintenance, extended inspection cycles, and reduced costs.

For Technical Teams: Greater attention to real operating conditions, process-device compatibility, and long-term system health.

It enables full-spectrum monitoring across instruments and systems—including DCS, SIS, CCS, pollution analyzers, gas detectors, metering instruments, and more.

6. Platform Architecture Overview

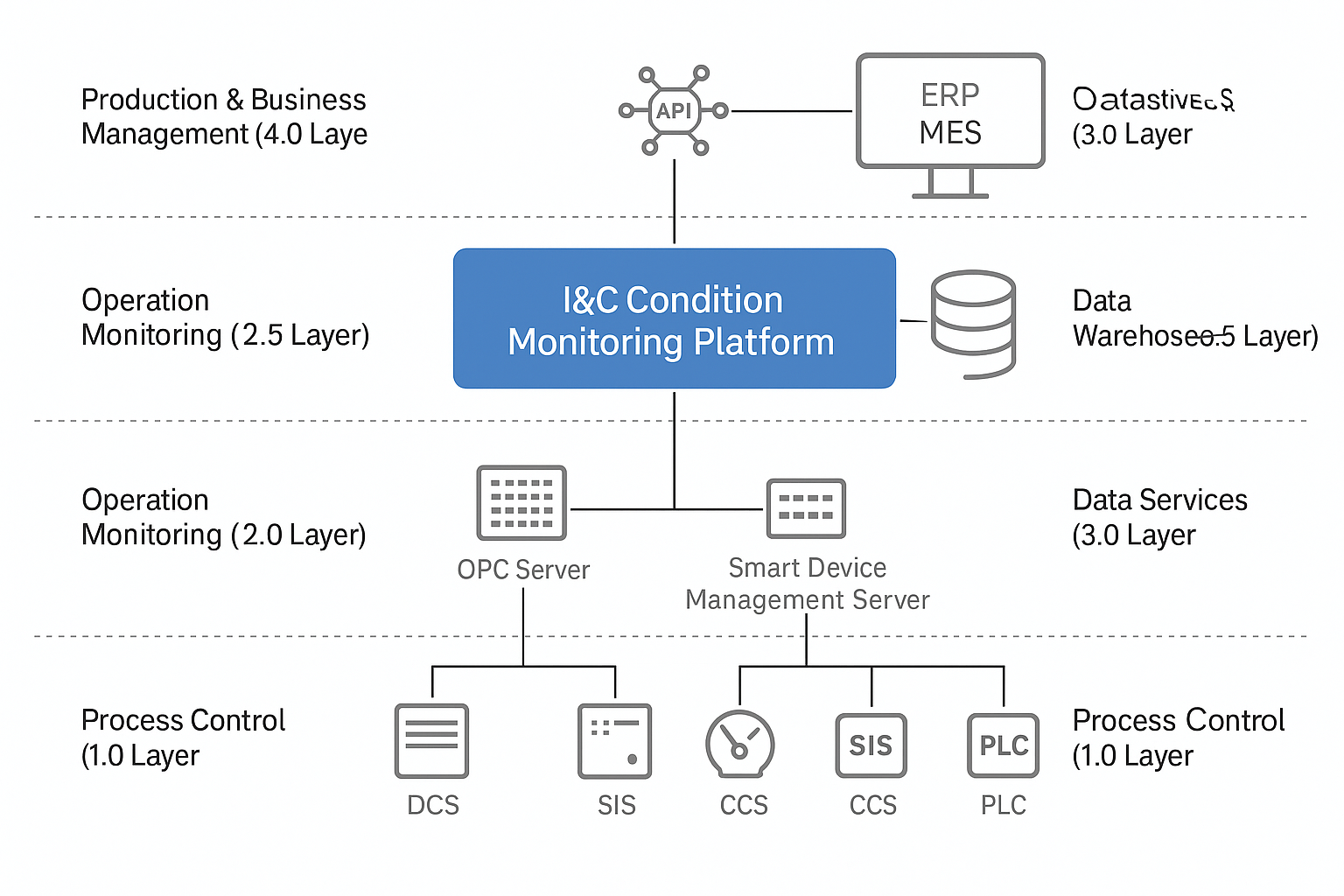

6.1 Network Topology

The architecture spans four layers:

Layer 1.0 – Process Control

Layer 2.0 – Operation Monitoring

Layer 3.0 – Data Services (Platform Layer)

Layer 4.0 – Production & Business Management

The monitoring platform resides at Layer 2.5 and connects to equipment such as smart/legacy transmitters, control systems, power supplies, and air supply monitors. Key components include:

OPC Servers: Collecting data from DCS and related systems.

Smart Device Management Servers: Supporting protocols like HART, FF, and Modbus.

Data Warehouses and Monitoring Stations: For data storage, analysis, configuration, and historical retrieval.

7. Real-World Applications

Case Study 1: Integrated Refining Enterprise

A refinery implemented a centralized monitoring platform following corporate guidelines. It monitors 30 units, covering:

Smart instruments (valve positioners, transmitters, mass flow meters)

Alarm KPIs, failure trends, and deviation analysis

Alarm event diagnosis, prediction, and closed-loop control

Over 226 fault detections within the first year

Case Study 2: Refinery Alarm Incident

In August 2021, the platform identified valve signal anomalies that hadn’t yet affected the process. Technicians intervened early, avoiding major shutdowns.

In December 2021, another fault (DCS cabinet power failure) was detected and resolved promptly via the platform.

8. Conclusion

I&C Condition Monitoring Platforms have become essential tools in the petrochemical industry’s digital transformation journey. They provide visibility into equipment health, enhance preventive maintenance strategies, and reduce unplanned downtime and safety incidents. As the industry evolves toward smart manufacturing, such platforms will play a pivotal role in enabling safer, more efficient, and more reliable operations.