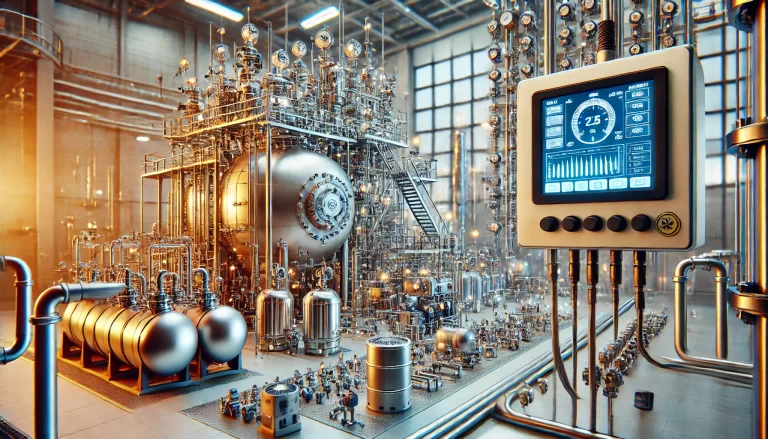

Chemical automation technology has long been integral to optimizing processes, enhancing productivity, and ensuring safety in the chemical industry. By leveraging advancements in electronics, microcontroller principles, programmable logic controllers (PLCs), and control technologies, chemical automation has transformed how parameters like temperature, pressure, flow rate, and composition are monitored and controlled. Looking ahead, the evolution of chemical automation is poised to shape the industry’s future through several key trends.

1. Intelligent and Autonomous Systems

Integration of Artificial Intelligence (AI)

Artificial Intelligence (AI) will play a pivotal role in chemical automation. Machine learning and deep learning algorithms can analyze vast amounts of production data to build intelligent models for complex chemical processes. These models enable real-time optimization, predictive maintenance, and fault diagnosis, reducing downtime and operational risks.

Example: A leading chemical manufacturer implemented AI to optimize reactor temperature control, achieving a 15% improvement in yield while reducing energy consumption.

Increased Use of Robotics

Robotic systems will increasingly be used for hazardous and repetitive tasks in chemical plants. Robots can handle material transportation, equipment inspection, and even dangerous chemical operations, improving worker safety and operational efficiency.

Example: Automated robotic systems deployed in chemical plants for hazardous waste handling reduced human exposure to toxic environments by 40%.

2. Digitization and Informatization

Big Data and Cloud Computing

Big data analytics is transforming decision-making in chemical production. By collecting, storing, and analyzing massive datasets, companies can uncover hidden patterns that inform process optimization, quality control, and energy efficiency. Cloud computing provides scalable computing resources, reducing infrastructure costs and enabling remote monitoring.

Example: A mid-sized chemical enterprise used cloud-based predictive analytics to monitor equipment health, reducing unplanned maintenance costs by 25%.

Industrial Internet of Things (IIoT)

IIoT connects devices, sensors, and systems to create a unified and intelligent production network. Real-time data from interconnected systems facilitates smarter decision-making, proactive maintenance, and improved resource utilization.

Example: A plant integrating IIoT-enabled sensors achieved a 20% reduction in water usage by identifying inefficiencies in its cooling processes.

3. Integration and Collaboration

Enhanced System Integration

The next generation of chemical automation will feature fully integrated systems from raw material handling to product delivery. Breaking down “information silos” allows seamless communication across different units, enabling centralized control and improved overall efficiency.

Example: An integrated automation system in a petrochemical plant reduced process variability by 30%, increasing throughput.

Collaborative Innovation

The chemical industry is likely to see strengthened collaboration among manufacturers, automation technology providers, and research institutions. These partnerships will accelerate the development of cutting-edge solutions tailored to industry needs.

Example: A consortium of chemical companies and academic researchers developed an advanced process control (APC) system that improved the efficiency of distillation columns by 18%.

4. Sustainability and Green Practices

Promotion of Clean Production Technologies

Sustainability is becoming a core focus. Clean production technologies aim to minimize pollution at the source, adopting processes that reduce waste and emissions.

Example: A specialty chemical company implemented solvent recovery technologies, cutting volatile organic compound (VOC) emissions by 35%.

Energy Management and Optimization

Energy optimization systems monitor and analyze energy consumption in real time, enabling efficient use of resources. By employing energy-efficient strategies, companies can reduce their carbon footprint and operational costs.

Example: A chemical plant’s energy management system saved $2 million annually by optimizing boiler operations and heat recovery processes.

Challenges and Opportunities

While these trends present exciting opportunities, they also pose significant challenges. High initial costs for advanced automation technologies, the need for skilled personnel, and cybersecurity risks are potential hurdles. However, the benefits of enhanced efficiency, sustainability, and safety outweigh the challenges, making investments in these technologies imperative.

Conclusion

The future of chemical automation lies in intelligent systems, digital transformation, integrated solutions, and sustainable practices. By embracing these trends and addressing associated challenges, the chemical industry can unlock new levels of efficiency, innovation, and environmental responsibility. Collaboration among stakeholders will be key to ensuring a smooth transition and realizing the full potential of these advancements.