The industrial landscape has witnessed transformative shifts over the centuries, with each phase of development bringing new paradigms and technologies. Industry 4.0 and Industry 5.0 are two such revolutionary phases that have reshaped how we think about manufacturing, technology, and human involvement. Although Industry 5.0 builds upon the foundation laid by Industry 4.0, the two are distinct in their focus, approach, and ultimate objectives. This article delves into the details, highlighting their differences and the implications for industries and society.

1. Core Concepts

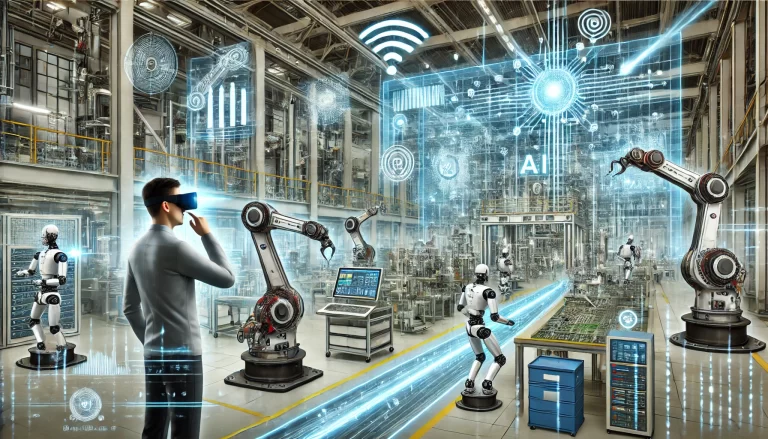

Industry 4.0, often referred to as the “Fourth Industrial Revolution,” is characterized by the integration of automation, artificial intelligence (AI), and the Internet of Things (IoT) into manufacturing processes. It aims to create “smart factories” where machines and systems communicate seamlessly, enabling data-driven decision-making and optimizing production efficiency.

In contrast, Industry 5.0 emphasizes human-machine collaboration. It represents a shift from mere automation to a synergistic partnership between humans and intelligent systems. The focus here is not just on efficiency but also on delivering personalized, sustainable, and human-centric solutions.

2. Objectives

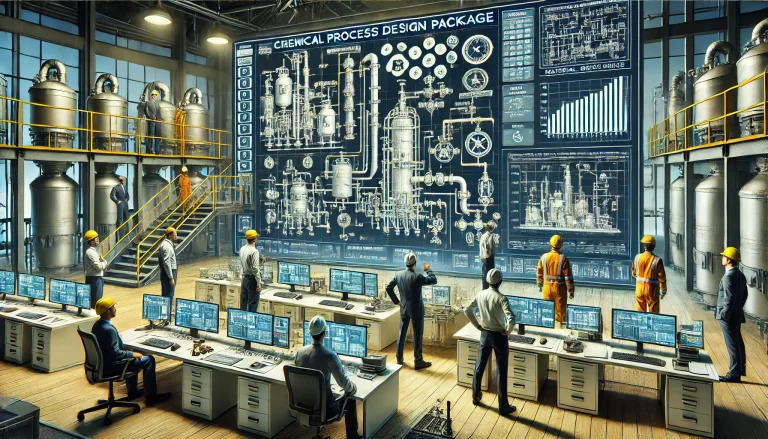

Industry 4.0: Efficiency and Optimization The primary goal of Industry 4.0 is to achieve maximum efficiency by automating repetitive and time-consuming tasks. Through technologies such as predictive maintenance, real-time monitoring, and autonomous systems, industries aim to minimize waste, reduce downtime, and enhance productivity.

Industry 5.0: Personalization and Sustainability Industry 5.0 moves beyond efficiency to prioritize individual needs and societal well-being. It focuses on tailoring production processes to meet customer-specific requirements, creating personalized products, and fostering sustainable practices that benefit both the environment and the workforce.

3. Technological Foundations

Industry 4.0:

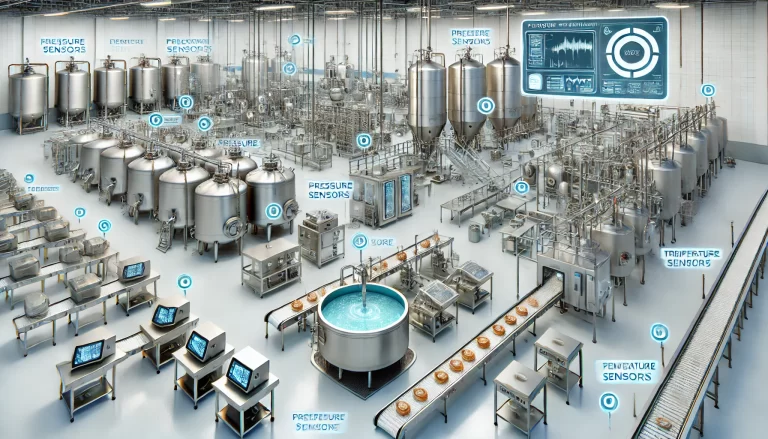

- IoT (Internet of Things): Devices and machines are interconnected, exchanging data to create a networked production system.

- Big Data and Analytics: Massive amounts of data are analyzed to optimize operations, predict trends, and identify inefficiencies.

- Automation and Robotics: Manufacturing processes are automated to reduce reliance on human labor.

- Cloud Computing: Data storage and processing are moved to the cloud for real-time access and scalability.

Industry 5.0:

- Collaborative Robots (Cobots): Unlike traditional robots in Industry 4.0, cobots are designed to work alongside humans, augmenting their capabilities rather than replacing them.

- Artificial Intelligence (AI): AI evolves to focus on understanding human behaviors and preferences, enabling better human-machine interaction.

- Sustainability Technologies: Innovations such as green energy solutions, circular economy models, and environmentally friendly production methods become central.

- Human-Machine Interfaces (HMIs): Enhanced interfaces enable seamless communication between humans and machines, allowing for intuitive and efficient collaboration.

4. Role of Humans

Industry 4.0: Humans play a supervisory role in the Industry 4.0 paradigm. Their primary responsibilities include monitoring automated systems, troubleshooting issues, and maintaining machinery. The overarching aim is to reduce human intervention in routine tasks to minimize errors and enhance efficiency.

Industry 5.0: Industry 5.0 redefines the role of humans, emphasizing their unique abilities in creativity, critical thinking, and decision-making. Machines take over monotonous and repetitive tasks, allowing humans to focus on innovation and problem-solving. This phase also recognizes the importance of employee well-being, aiming to create meaningful and fulfilling work environments.

5. Economic and Social Impacts

Industry 4.0:

Economic Impact: Industry 4.0 has driven significant cost reductions and productivity gains by optimizing resources and streamlining supply chains. However, it has also led to challenges such as job displacement, as automation replaces human workers in many roles.

Social Impact: The reliance on automation has raised concerns about workforce displacement and the widening skills gap. Workers are required to reskill and adapt to increasingly technical roles, which can be a barrier for those without access to education and training.

Industry 5.0:

Economic Impact: Industry 5.0 shifts the focus toward creating value-added products that cater to individual preferences. This approach encourages innovation and opens up new markets for personalized goods and services.

Social Impact: By fostering collaboration between humans and machines, Industry 5.0 seeks to address the societal challenges posed by Industry 4.0. It emphasizes upskilling the workforce, improving job satisfaction, and promoting inclusivity. Moreover, the emphasis on sustainable practices aligns with global efforts to combat climate change and reduce environmental degradation.

6. Sustainability and Ethics

One of the most significant differences between the two paradigms lies in their approach to sustainability and ethical considerations:

Industry 4.0: The focus is predominantly on optimizing processes and resources, with less attention to environmental and social impacts. While efficiency indirectly supports sustainability, it is not a primary goal.

Industry 5.0: Sustainability is a cornerstone of this phase. By adopting circular economy principles, reducing carbon footprints, and prioritizing ethical labor practices, Industry 5.0 aims to align industrial practices with broader societal and environmental goals.

7. Challenges and Future Prospects

Challenges in Industry 4.0:

- High initial investment in automation and IoT infrastructure.

- Security concerns due to the interconnected nature of systems.

- Workforce displacement and the need for continuous reskilling.

Challenges in Industry 5.0:

- Balancing human-machine collaboration without over-relying on either.

- Developing technologies that are intuitive and accessible to a diverse workforce.

- Ensuring ethical considerations are embedded in AI and robotics systems.

Future Prospects: Industry 4.0 and 5.0 are not mutually exclusive but complementary. As Industry 5.0 gains traction, it will integrate the automation and data-driven capabilities of Industry 4.0 while adding a human-centric layer. The result will be an industrial ecosystem that is efficient, sustainable, and socially responsible.

Conclusion

While Industry 4.0 revolutionized manufacturing by prioritizing automation and efficiency, Industry 5.0 heralds a new era of personalization, sustainability, and human-centric solutions. Together, they represent a continuum of progress, each building upon the achievements of the other. As industries transition from Industry 4.0 to Industry 5.0, the ultimate goal will be to create a harmonious balance between technology, humanity, and the environment—ensuring a future that is not only prosperous but also inclusive and sustainable.