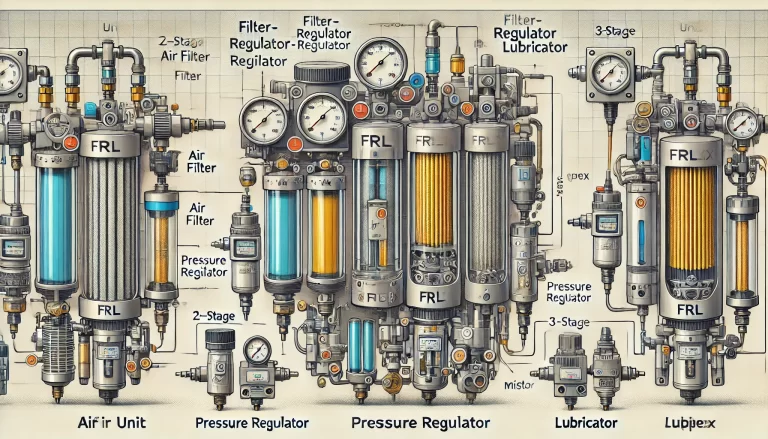

Pneumatic systems are widely used in various industries for automation and process control due to their reliability, simplicity, and efficiency. To ensure the optimal performance of these systems, it’s important to condition the air used to drive pneumatic actuators and other devices. This is where FRL units (Filter-Regulator-Lubricator) come into play. The two most common types of FRL units are two-stage (duplex) and three-stage (triplex) units. Understanding the differences between them helps ensure the right choice for your pneumatic system’s needs.

Overview of Pneumatic FRL Units

FRL units are used to prepare compressed air before it enters the pneumatic components, removing contaminants, regulating pressure, and sometimes adding lubrication to ensure smooth operation. Proper air treatment increases system efficiency, reduces wear and tear on components, and enhances the overall durability of the pneumatic system.

Let’s dive deeper into the specific components and differences between two-stage and three-stage FRL units.

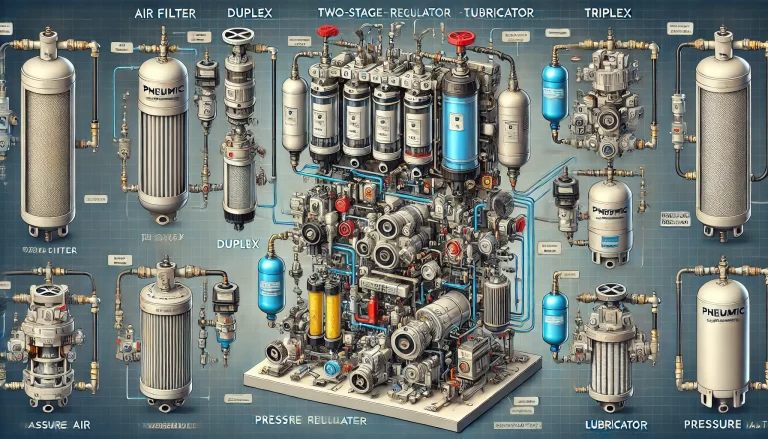

Three-Stage FRL Units (Triplex)

Three-stage FRL units include three essential components:

- Air Filter

- Pressure Regulator

- Lubricator

1. Air Filter:

- Function: The air filter is responsible for removing dust, dirt, oil particles, and moisture from the compressed air supply. Contaminants can cause damage or clog pneumatic components, leading to inefficiencies or failures.

- Importance: Clean air prevents the accumulation of dirt inside actuators, cylinders, and valves, prolonging their lifespan and reducing maintenance costs.

2. Pressure Regulator (Regulator):

- Function: The regulator controls the air pressure entering the pneumatic system. It ensures that the air pressure is maintained within a certain range to optimize performance and protect equipment from being exposed to excessively high pressure.

- Importance: Without proper pressure control, too much or too little air pressure could damage equipment or reduce operational efficiency. The regulator ensures consistent performance.

3. Lubricator:

- Function: The lubricator adds a fine mist of oil into the compressed air stream. This oil lubricates the moving parts of pneumatic components, such as actuators, valves, and cylinders, which helps reduce friction and wear.

- Importance: The lubricator is essential in systems where lubrication is necessary for optimal functioning and longevity. It extends the life of pneumatic components by reducing friction and heat buildup.

When to Use a Three-Stage FRL Unit? A three-stage FRL unit is ideal for pneumatic systems that involve components requiring lubrication, such as air tools or cylinders operating at high speeds or in environments where dry air could lead to premature wear. The oil mist from the lubricator ensures smooth motion and prevents seizing or sticking, enhancing system performance and reliability.

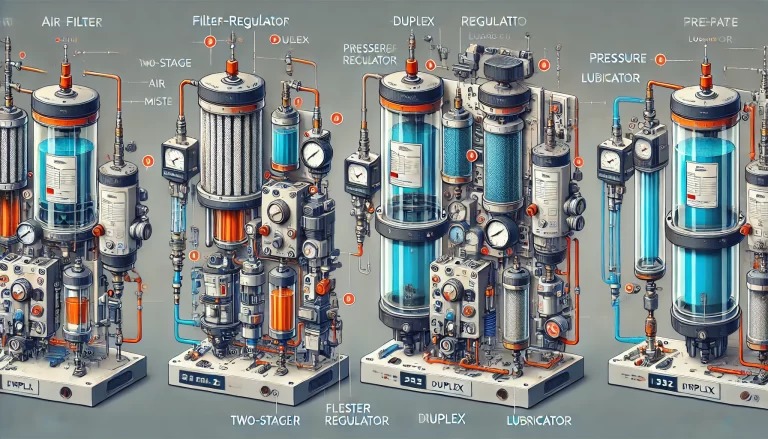

Two-Stage FRL Units (Duplex)

Two-stage FRL units consist of:

- Air Filter

- Pressure Regulator

1. Air Filter:

- Function: Similar to the three-stage unit, the filter removes contaminants like dirt, dust, and moisture from the compressed air to protect downstream equipment.

2. Pressure Regulator:

- Function: The regulator ensures the air pressure is stable and within the desired operating range. This is crucial for maintaining consistent performance in the pneumatic system.

Noticeably Absent: The Lubricator A two-stage unit does not include the lubricator. This setup is sufficient for pneumatic systems where lubrication is not required or where air tools and actuators are self-lubricating. Modern pneumatic components, in fact, often use sealed bearings or non-lubricated designs that do not require additional oil injection.

When to Use a Two-Stage FRL Unit? Two-stage FRL units are suitable for applications where lubrication is not necessary or could even be detrimental, such as in clean environments like food and beverage processing, or in medical and pharmaceutical industries where oil contamination must be avoided. Additionally, for systems using components that are pre-lubricated or that do not rely on oil, a two-stage FRL is a more straightforward, cost-effective solution.

Key Differences:

- Components:

- The three-stage unit includes a lubricator, while the two-stage unit does not.

- Applications:

- Three-stage units are best suited for pneumatic systems that need additional lubrication for moving parts. In contrast, two-stage units are appropriate for applications where lubrication is unnecessary or undesirable.

- Maintenance:

- A three-stage unit requires monitoring of the oil levels in the lubricator and occasional replenishment, adding a layer of maintenance compared to a two-stage system.

- Cost:

- Two-stage FRL units tend to be less expensive, as they have fewer components and require less upkeep. However, in systems where lubrication is necessary, the extra cost of a three-stage unit can pay off by extending equipment life and improving performance.

Choosing the Right FRL Unit for Your System

Selecting between a two-stage and three-stage FRL unit boils down to understanding the specific requirements of your pneumatic system:

- Does your system need lubrication? If so, a three-stage unit is necessary.

- Are you working in an environment where oil contamination is a concern? If yes, a two-stage unit is the better choice.

- What kind of components are used in your system? For pre-lubricated or sealed components, a two-stage system is sufficient, while a three-stage unit should be considered for components that benefit from added lubrication.

Conclusion

Both two-stage and three-stage FRL units are essential tools in optimizing the performance and longevity of pneumatic systems, but they serve different purposes. A three-stage FRL unit, with its additional lubricator, provides vital lubrication for systems that need it, while a two-stage unit is sufficient for systems that do not require lubrication. By understanding the distinctions between these two types, you can ensure your pneumatic system runs smoothly, efficiently, and with minimal wear and tear.