Overview

In various control systems, both “chain locking” and “interlocking” are essential mechanisms for ensuring operational safety and coordination. Although these two concepts are sometimes used interchangeably, they possess distinct characteristics and applications. This article delves into their definitions, implementation methods, and practical applications to provide a comprehensive understanding of their differences.

Definitions and Distinctions

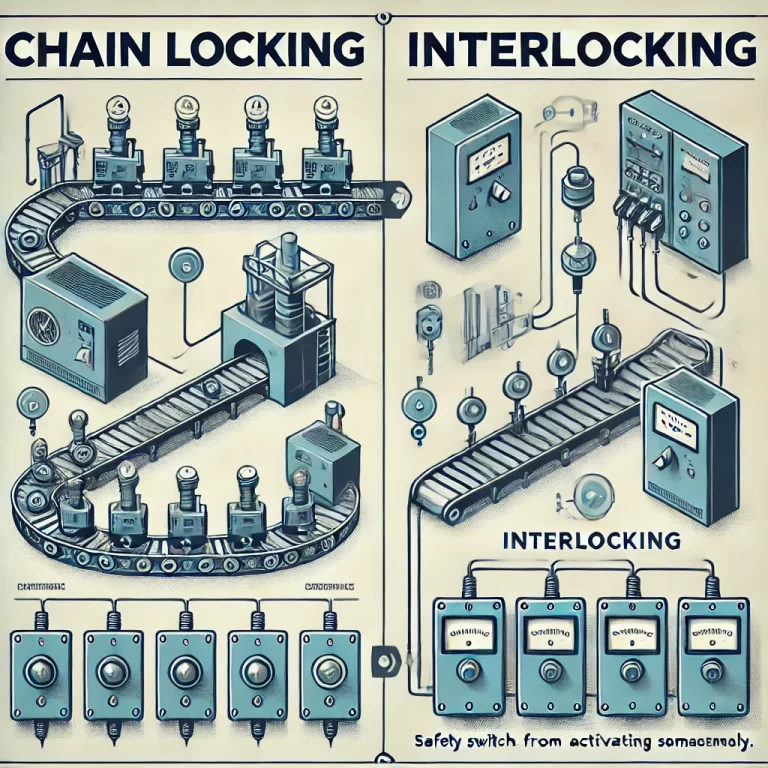

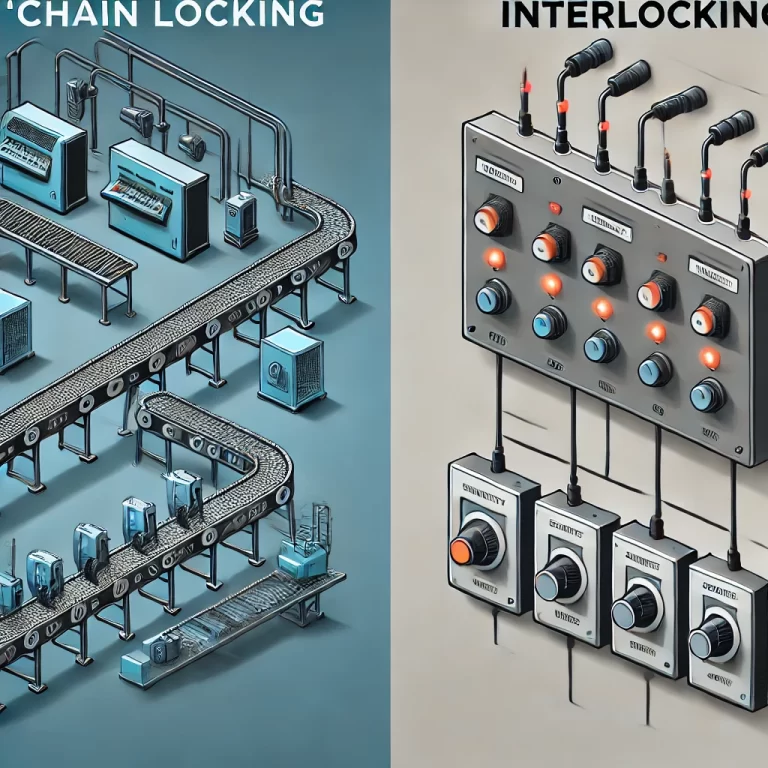

Chain Locking refers to the control mechanism where electrical signals link different devices and components, creating a mutual restriction that coordinates their operation. This system ensures that devices and components perform tasks in a specific sequence, preventing operational errors and enabling synchronized control.

Interlocking, on the other hand, focuses on the interaction between adjacent devices. A change in the state of one device directly influences another, serving as a safeguard against repeated or conflicting operations. Interlocking is primarily designed to enhance safety, prevent human errors, and ensure the reliable functioning of safety protection mechanisms.

Implementation Methods

Chain Locking can be implemented through two primary methods:

Mechanical Contact Chain Locking: Utilizes mechanical contacts to control actions. This method is known for its reliability, cost-effectiveness, and minimal electromagnetic interference.

Electronic Chain Locking: Employs logic and digital circuits to establish interconnections between signals. This method offers a broader application range and higher stability.

Interlocking is typically realized through:

Mechanical Interlocking: Relies on mechanical mechanisms to enforce mutual restrictions between device states. It is highly reliable and stable, making it ideal for critical safety functions.

Electrical Interlocking: Uses electrical signals to manage state interactions. This method features fast response times and user-friendly operation.

Practical Applications

In industrial settings, the distinction between chain locking and interlocking becomes evident through their applications:

Chain Locking is widely used in automated production lines to coordinate sequential machine operations. For example, in conveyor systems, one machine must complete its cycle before the next machine starts, ensuring smooth and efficient production.

Interlocking is crucial in safety-critical systems, such as elevator controls and power distribution networks. For instance, in power grids, interlocking mechanisms prevent simultaneous activation of conflicting circuits, reducing the risk of short circuits or equipment damage.

In fire protection systems, the concepts diverge further. Interlocking often involves electrical or mechanical contacts to ensure devices operate safely and in the correct sequence. Chain locking, in contrast, may trigger subsequent device actions directly when certain conditions are met, without involving the fire alarm system.

Conclusion

While both chain locking and interlocking play vital roles in control systems, their functions, implementation methods, and applications differ significantly. Chain locking emphasizes sequence control and coordination, whereas interlocking focuses on safety and error prevention. Understanding these distinctions allows for more effective design and management of complex control systems, ensuring operational efficiency and safety.