Pressure is everywhere in industrial production and daily life. There are “gauge pressure” and “absolute pressure” in industry, and there are “gauge pressure” and “absolute pressure” in life. Understand different types of pressure and make use of various pressures.

Gauge pressure, also known as gauge pressure, generally refers to the measured pressure of a pressure gauge or pressure transmitter, and its zero point is atmospheric pressure.

Absolute pressure, the abbreviation of absolute pressure, is the actual pressure that an object bears, and its zero point is absolute vacuum.

The simplest way to distinguish the difference between gauge pressure and absolute pressure is the difference in the reference (zero point).

In practical engineering applications, the measurement type selected by most applied pressure gauges or pressure transmitters is gauge pressure.

Gauge pressure is a relative pressure (Relative Pressure), which is a pressure expression method based on atmospheric pressure as a reference, that is, when the pressure gauge is placed in the air or the pressure of the measured system is equal to the local atmospheric pressure, its indication value is 0.

Absolute pressure gauges also have certain applications in fields such as industrial process control and scientific experiments.

Absolute pressure is a pressure expression method based on absolute vacuum. An absolute pressure gauge is a pressure gauge that directly measures absolute pressure. When an absolute pressure gauge is placed in the air, its indicated value is the local atmospheric pressure. Only when the system measured by the absolute pressure gauge is in absolute vacuum, the indicated value is 0.

I. Definition of pressure

In physics, pressure is the vertical force per unit area. In manufacturing, pressure not only affects the shape and structure of objects, but is also directly related to the stability and safety of the process. This seemingly simple definition contains a wealth of application possibilities. From supporting skyscrapers to designing efficient aircraft wings, the concept of pressure is everywhere.

II. Units of pressure

There are many different units of pressure, reflecting its wide application in different fields:

• Pascal (Pa): The standard unit of pressure in the International System of Units (SI), 1N (Newton) force per m² (square meter), that is, 1Pa equals 1N/m²

• Kilopascal (kPa): 1kPa equals 1000Pa, commonly used in industrial measurement

• Megapascal (MPa): 1MPa equals 1000kPa, or 1000000Pa, commonly used in industrial measurement

• Bar: 1bar equals 100000Pa, commonly used in engineering

• psi (pounds per square inch): 1psi is approximately equal to 6894.76Pa, mainly used in the Anglo-American system

• Standard atmospheric pressure (atm): equal to 101325 Pa, commonly used in meteorology

Definition of gauge pressure

Gauge pressure, as the name suggests, is the pressure measurement relative to the local atmospheric pressure. It tells us how much higher or lower the measured pressure is than the surrounding air pressure (usually atmospheric pressure).

How gauge pressure works

Gage pressure measurement determines the pressure by comparing it to atmospheric pressure. If the gauge pressure is positive, it means the pressure is higher than atmospheric pressure; if it is negative, it means the pressure is lower than atmospheric pressure.

III. Absolute pressure

1. Definition of absolute pressure

Absolute pressure is the pressure measurement relative to a complete vacuum. It directly reflects the absolute value of pressure, including all pressures including atmospheric pressure.

2. Working principle of absolute pressure

Absolute pressure measurement ignores atmospheric pressure and focuses on the pressure on the object itself.

IV. Comparison between gauge pressure and absolute pressure

1. Differences in measurement principles

The main difference between gauge pressure and absolute pressure is the different reference pressures. Gauge pressure is measured relative to atmospheric pressure, while absolute pressure is measured relative to a complete vacuum. This leads to differences in application and interpretation between the two.

2. Conversion relationship

The conversion from gauge pressure to absolute pressure requires consideration of the current atmospheric pressure value, which is usually achieved by adding or subtracting a standard atmospheric pressure value. The conversion formula is as follows:

• Absolute pressure = gauge pressure + atmospheric pressure

• Gauge pressure = absolute pressure – atmospheric pressure

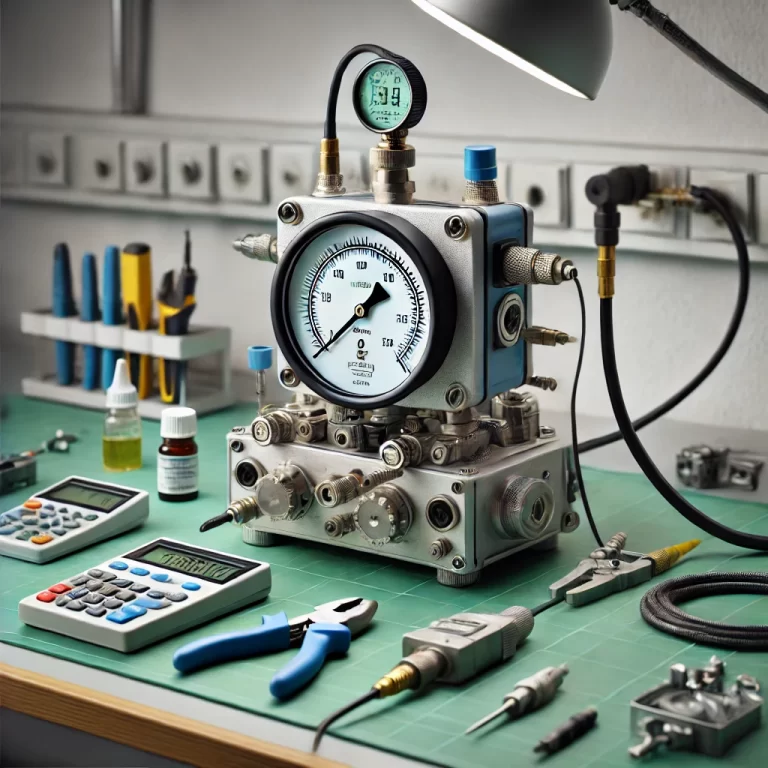

V. Pressure measurement technology

1. Types of pressure sensors

Pressure sensors include mechanical, resistive, piezoelectric and other types, each of which has its specific working principle and application scenario.

Jingcheng Engineering Breathing Blaster uses Fairchild pressure sensor

2. Accuracy of pressure measurement

Factors that affect the accuracy of pressure measurement include temperature changes, sensor accuracy, environmental conditions, etc., which need to be considered and controlled in design and use.

3. Calibration of pressure measurement

Regular calibration of pressure measurement equipment is an important step to ensure its accuracy and reliability, especially in precision manufacturing and safety-critical applications.

–

For example: the gauge pressure is 0.5MPaG, according to the above formula, absolute pressure = (0.5 + 0.101325) MPaA = 0.601325MPaA.

Note 1: Strictly speaking, atmospheric pressure needs to be confirmed according to working conditions, which is related to the local altitude and weather conditions. Many times, for convenience, the standard atmospheric pressure 1atm = 101.325kPa is directly taken.

Note 2: According to the corresponding English words Gauge and Absolute abbreviations, the suffix “G” or “A” is usually added to the standard unit to standardize the gauge pressure and absolute pressure. This format is basically used in the information provided by the design institute.

Note 3: If a gauge pressure sensor is used in an application and the actual measurement task is to measure absolute pressure, the following additional errors must be expected:

① ±30mbar caused by weather changes

② When the position changes, it can reach up to 200mbar (such as rising from sea level to 2000m)

Depending on the measurement range, these errors may be large (such as in pneumatic devices with a measurement range of 1bar) or negligible (such as in hydraulic devices with a measurement range of 400bar).

The standard atmospheric pressure (atm) value was proposed by Italian physicist Torricelli in 1644, and he also co-invented the mercury barometer in the same year. Unfortunately, In 1647, Torricelli died of illness at the age of 39.

In engineering practice, it is very necessary to distinguish between gauge pressure and absolute pressure. For example, many calculations such as the conversion of the working volume flow rate of general gas to the standard volume flow rate involve pressure. Do you know whether the gauge pressure or absolute pressure is used in the calculation?

For the sake of memory, let’s recall that gauge pressure is measured relative to atmospheric pressure. Changes in atmospheric pressure caused by altitude or weather conditions will directly affect the measurement accuracy of gauge pressure. In other words, the measurement of gauge pressure is not accurate, while absolute pressure is always certain.

Because absolute pressure is certain, the pressure used in various formulas and calculations is basically absolute pressure.

Finally, in order to ensure the accuracy and reliability of the measurement results, pressure gauges and pressure transmitters need to be calibrated and verified regularly based on factors such as the accuracy level and use environment.