Ultrasonic level meters, with their advanced technological attributes, play an increasingly critical role in environmental engineering, notably in wastewater treatment, water quality monitoring, and resource recycling projects. This article systematically explores their core advantages from the perspectives of technical performance, safety, economic value, and intelligent integration.

1. Non-Contact Measurement: Ensuring Safety and Purity

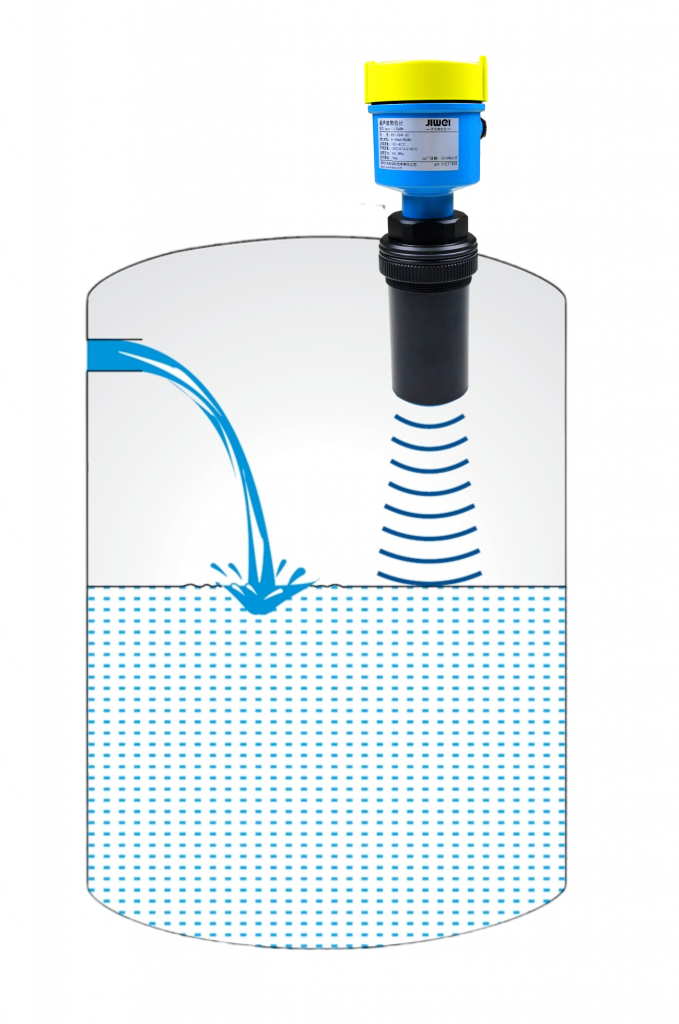

Avoiding Contamination and Corrosion

Environmental engineering often involves handling strongly corrosive substances (such as acidic or alkaline wastewater), highly viscous materials (like sludge), or toxic liquids (such as heavy-metal-containing wastewater). Ultrasonic level meters use sound reflection to perform non-contact measurements, completely eliminating the corrosion, scaling, and contamination issues that commonly occur with traditional float or capacitive level meters. For instance, traditional meters used in electroplating wastewater tanks typically have a service life of less than 6 months due to corrosion, while ultrasonic meters can last beyond 5 years.

Intrinsic Safety in Hazardous Environments

For combustible or explosive environments like biogas digesters or chemical waste tanks, ultrasonic meters feature explosion-proof designs or externally-mounted sensors. This installation method requires no tank penetration, completely avoiding leakage or explosion risks due to seal failures. A hazardous waste treatment plant successfully deployed external ultrasonic meters in toluene storage tanks, achieving ATEX explosion-proof certification and reducing annual maintenance costs by 85%.

2. Adaptability to Complex Conditions: The Foundation of Accurate Monitoring

Reliable Performance in Extreme Environments

Ultrasonic meters offer wide temperature tolerance (-40℃ to 150℃) and high ingress protection ratings (IP68), ensuring reliable performance in harsh environments such as sludge drying facilities (high temperatures), open-air water reservoirs in cold climates, and humid, dusty conditions like landfill leachate treatment plants. Built-in temperature compensation algorithms correct real-time speed-of-sound variations, achieving measurement accuracy within ±3mm. One coastal sewage treatment plant maintained 99.2% data accuracy even under severe typhoon-induced heavy rainfall.

Exceptional Interference Resistance

Equipped with dynamic echo-processing technologies such as intelligent echo tracking and multi-target identification, ultrasonic meters effectively filter out interference from foam, suspended solids, or turbulence caused by agitation. In aeration tanks, these meters accurately distinguish real liquid surface levels beneath surface foam, enabling precise control of aeration blower speeds and reducing energy consumption by 15-20%.

3. Economic Efficiency and Simplified Maintenance: Minimizing Lifecycle Costs

Quick Installation and Zero Modification Costs

Externally-mounted ultrasonic meters require no production downtime or structural modifications, dramatically reducing installation complexity and costs. A municipal sewage pumping station retrofit completed sensor deployment within just two hours, cutting installation time by 90% compared to conventional tank penetration methods, and eliminating welding-related safety risks.

Low Maintenance and Durable Design

With no moving mechanical parts, ultrasonic meters boast a Mean Time Between Failures (MTBF) exceeding 100,000 hours, extending typical maintenance cycles to 2-3 years. An industrial wastewater facility experienced annual maintenance costs dropping from approximately $18,000 to just $2,200, with equipment uptime improved to 99.5% after switching to ultrasonic meters.

4. Intelligent Integration: Driving Digitalization in Environmental Projects

Multi-Parameter Data Integration

Advanced ultrasonic meters integrate temperature and pressure sensors, simultaneously outputting parameters like liquid levels, density, and volumetric flow. These data streams can interface seamlessly with SCADA systems or cloud platforms via Modbus, HART, and other communication protocols. In a smart water project, integrated ultrasonic data analysis coupled with real-time pH and COD metrics optimized chemical dosing, reducing chemical waste by 30%.

AI-Driven Predictive Maintenance

With machine-learning algorithms analyzing historical echo signal data, ultrasonic meters autonomously detect probe contamination, abnormal sound velocity, and other issues, providing proactive maintenance alerts. A waste-to-energy facility leveraged AI-enabled ultrasonic meters to predict sludge buildup trends in leachate tanks, adjusting cleaning schedules from quarterly to on-demand, improving maintenance efficiency by 40%.

5. Versatile Applications: Covering the Entire Environmental Industry Spectrum

Universal Media Compatibility

Ultrasonic meters handle a wide range of media—from clean water and wastewater to oily mixtures and solid-containing slurries—by adjusting frequencies (low frequencies for strong penetration, high frequencies for greater accuracy). For example, a kitchen waste treatment facility solved radar-based detection issues caused by low dielectric constants by deploying 20 kHz low-frequency ultrasonic meters.

Adaptability to Specialized Structures

Ultrasonic meters with narrow beam angles (8°) or guided-wave designs effectively reduce echo interference in narrow or irregular tanks, such as conical sedimentation basins or tight underground conduits. In a small-diameter (0.8m) underground pipe monitoring system, ultrasonic meters achieved liquid level measurement accuracy within ±5mm, playing a key role in urban flood prevention.

Conclusion: A Driving Force for Environmental Engineering Upgrades

Ultrasonic level meters, through their non-contact safety measurements, exceptional adaptability to complex environments, lifecycle cost advantages, and intelligent integration capabilities, have become a critical technology for upgrading environmental engineering projects. As global initiatives like carbon neutrality progress, further integration with IoT and digital twin technologies promises enhanced precision in wastewater treatment, efficiency in resource recycling, and intelligence in environmental management, ultimately supporting sustainable development.