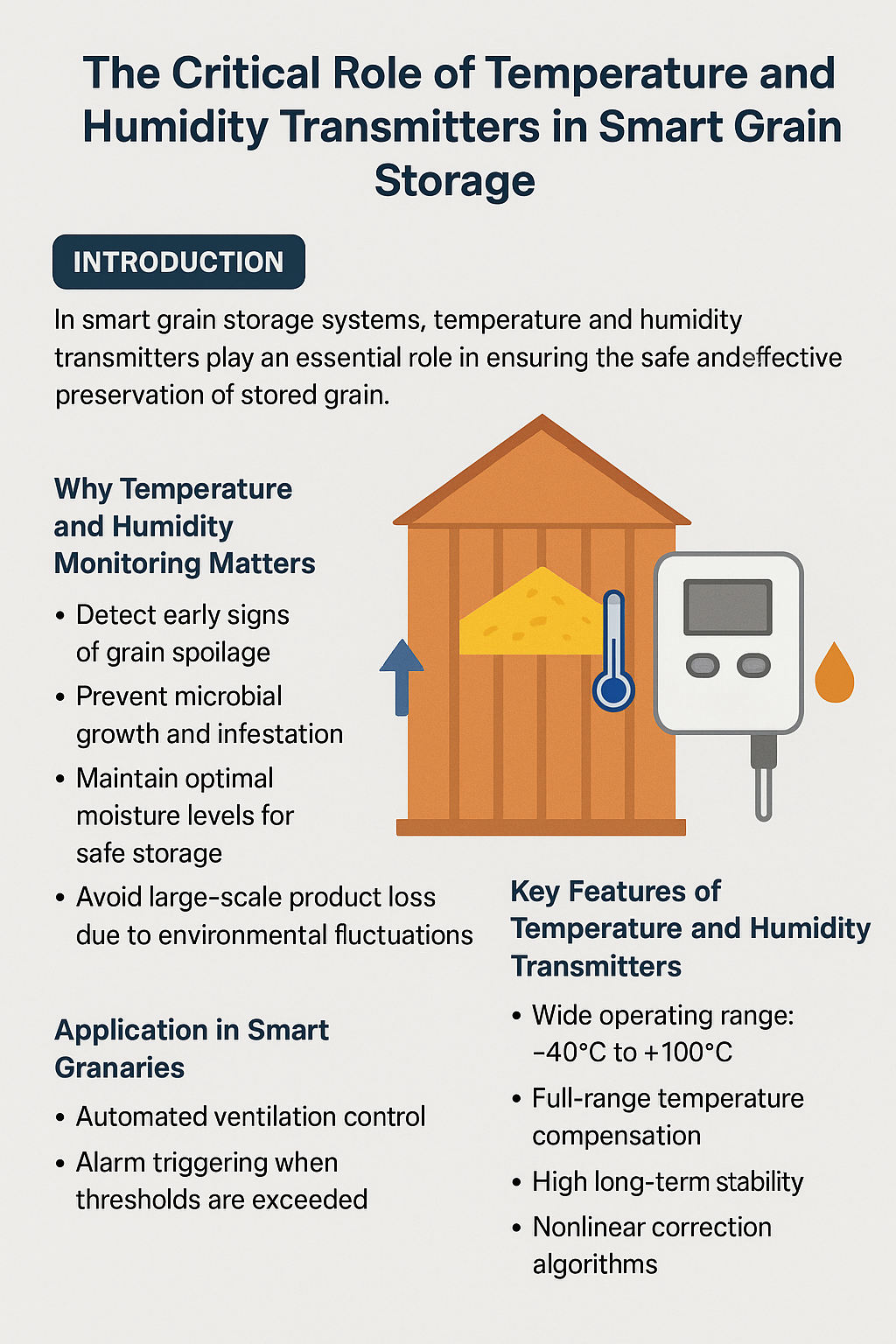

1. Introduction

In smart grain storage systems, temperature and humidity transmitters play an essential role in ensuring the safe and effective preservation of stored grain. Among all monitoring factors in a grain silo, controlling the internal temperature and humidity is of utmost importance. These two environmental parameters directly impact the quality, safety, and shelf life of stored grain.

2. Why Temperature and Humidity Monitoring Matters

During long-term storage, grains with high moisture content are prone to self-heating, which may lead to mold growth, fermentation, and even spontaneous combustion in extreme cases. This can result in severe deterioration and economic losses on a national scale. Internal temperature monitoring is especially critical, as changes in grain core temperature are often the first indicator of quality degradation.

By using temperature and humidity transmitters, warehouse operators can:

Detect early signs of grain spoilage

Prevent microbial growth and infestation

Maintain optimal moisture levels for safe storage

Avoid large-scale product loss due to environmental fluctuations

3. Key Features of Temperature and Humidity Transmitters

Modern transmitters used in grain silos are designed to meet the demands of harsh and variable environments. Notable technical features include:

Wide operating range: -40°C to +100°C, suitable for most grain storage conditions

Full-range temperature compensation: Ensures accurate readings across the entire temperature span

High long-term stability: Minimal drift over extended use

Compact design: Easy installation within silo structures or ducting systems

Strong anti-interference capabilities: Reliable performance even in electrically noisy environments

High measurement accuracy: Nonlinear correction algorithms improve data reliability

Multiple output formats: Supports both analog (4–20 mA) and digital (RS485) outputs for integration with PLCs or remote monitoring platforms

4. Application in Smart Granaries

The integration of temperature and humidity transmitters into smart warehouse systems enables real-time environmental data acquisition. This data can be transmitted to a central control system for:

Automated ventilation control

Alarm triggering when thresholds are exceeded

Historical data analysis for predictive maintenance

Enhanced traceability and quality control of stored batches

By continuously maintaining the warehouse within a predefined temperature-humidity envelope, the system helps extend grain shelf life, reduce the need for fumigation or reprocessing, and ultimately ensure food security.

5. Conclusion

Temperature and humidity transmitters are indispensable tools in modern grain storage management. Their ability to provide precise, real-time environmental feedback not only helps in preserving grain quality but also supports automation, reduces human intervention, and enhances operational efficiency.

For any enterprise or facility involved in bulk grain storage, investing in a robust temperature and humidity monitoring system is a critical step toward achieving smart agriculture and sustainable food preservation.