Hydropower generation harnesses the potential energy of elevated water sources—such as rivers, lakes, or reservoirs—and converts it into mechanical energy via a water turbine, which in turn drives a generator to produce electricity. As a renewable and environmentally friendly energy source, hydropower plays a vital role in the global energy mix.

Pressure sensors are essential components in the safe and stable operation of hydropower systems. These sensors typically feature stainless steel isolation diaphragms and OEM-grade sensing elements. They undergo precise laser trimming and wide-range temperature compensation to ensure zero offset and sensitivity stability. Integrated amplification circuits housed within stainless steel enclosures convert the raw pressure signal into a standardized 4–20 mA output, enabling seamless integration with control and monitoring systems.

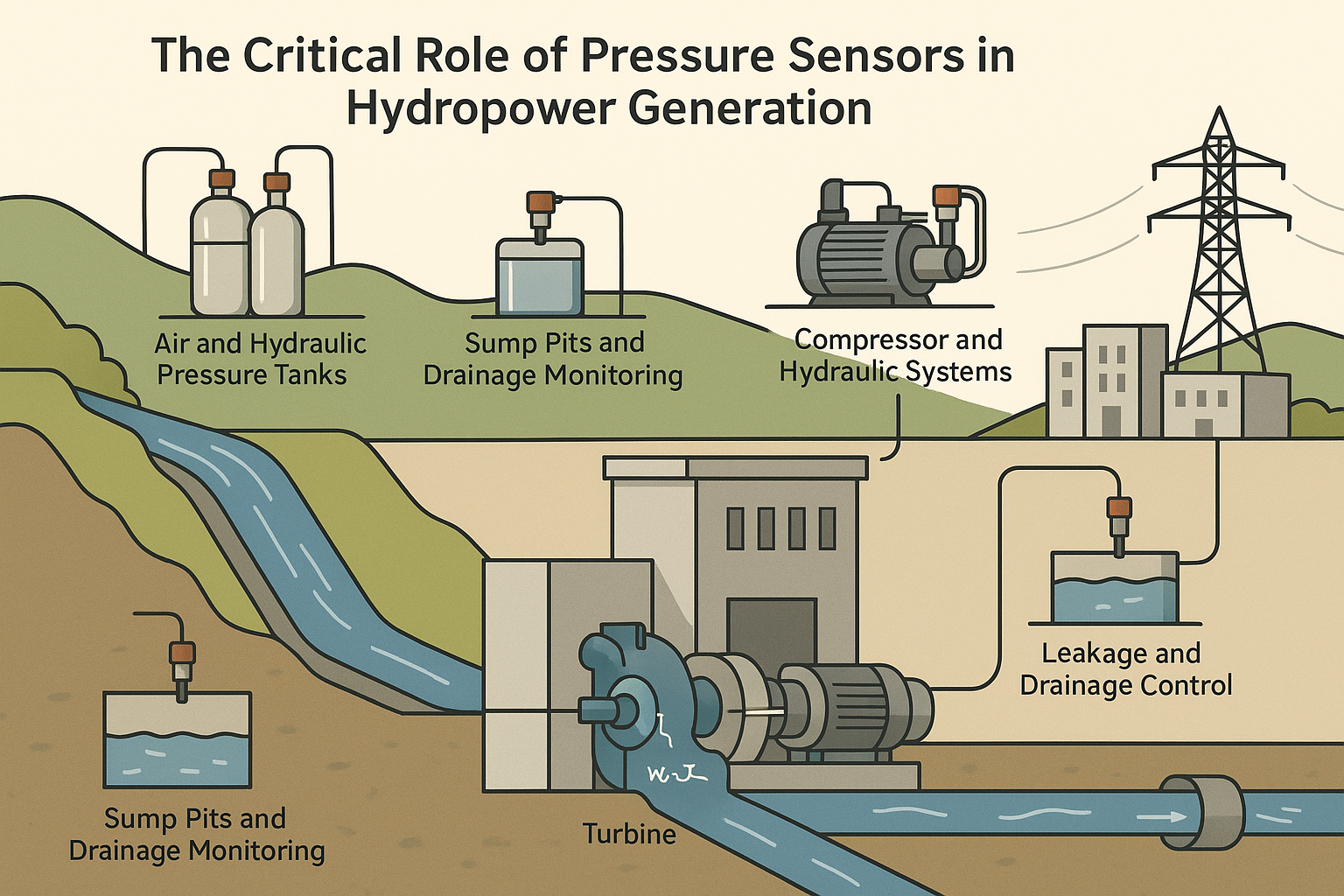

Key Applications in Hydropower Facilities:

Air and Hydraulic Pressure Tanks:

Pressure sensors continuously monitor the pressure inside compressed air and hydraulic oil tanks. This helps prevent system failures due to overpressure or pressure loss, which could lead to unplanned shutdowns of turbine units.Sump Pits and Drainage Monitoring:

By measuring hydrostatic pressure, sensors provide accurate water level data in sump wells. This information is crucial for initiating timely drainage to prevent flooding of equipment areas or powerhouses.Compressor and Hydraulic Systems:

These auxiliary systems rely on pressure sensors for maintaining optimal working conditions and ensuring the stability of power generation operations.Leakage and Drainage Control:

Pressure sensors are deployed to detect abnormal water accumulation or seepage, triggering drainage pumps or alarms to mitigate water ingress risks.

System Redundancy for Enhanced Reliability

To guarantee operational safety, critical measuring points are often equipped with redundant pressure sensor setups—typically two or even three sensors per location. This redundancy ensures continued monitoring in the event of sensor failure, thereby minimizing the risk of equipment damage, process disruption, or plant shutdown.

In summary, pressure sensors are not merely auxiliary components in hydropower plants—they are integral to real-time monitoring, preventive maintenance, and operational security. Their precise and reliable performance helps maintain system integrity and supports the long-term sustainability of hydropower infrastructure.