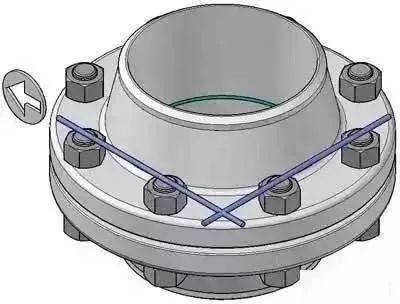

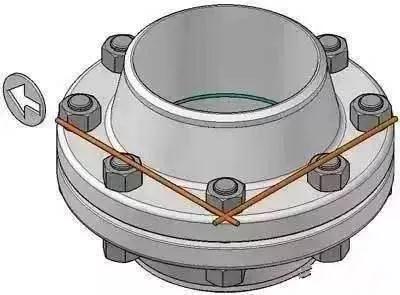

ASME B16.5 clearly specified the number of bolt holes and the diameter of bolt holes. The number and diameter of bolt holes are different because of the different pressure levels of flanges, but the number and diameter of bolt holes are the same regardless of the type of flange. The number of bolt holes in flange is even (2.4.6, etc.) evenly distributed in the diameter of bolt holes.

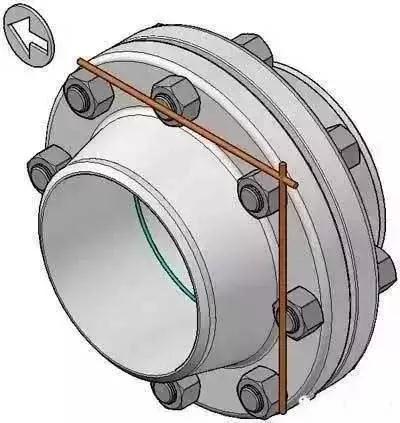

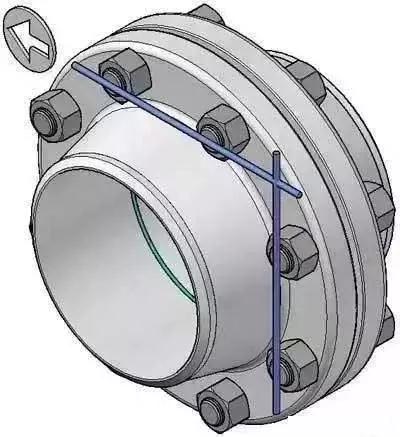

In the purchase of the instrument, in addition to the various data of the instrument to be calibrated, the location of bolt holes on the flange is also particularly important. In general, when making flange, there will be a sentence: all flange bolt holes across the center. For the vertical flange sealing surface, the bolt holes should be straddled on both sides of the vertical line and the horizontal midline.

The location of flange bolt holes is very important. It is not allowed to fail to meet the standard positioning. Unless it is a clear requirement of the customer. The centerline rule is that every responsible manufacturer should be familiar with it and follow it.