Dissolving copper is a part of the production of copper foil, using a movable cover in a certain volume, adding copper raw materials, concentrated sulfuric acid, and pure water into the molten copper tank, and sandblasting to produce a certain concentration of copper sulfate solution. Therefore, it is critical to measure the level of the dissolved copper filling. We have seen a case of a radar level meter measuring the dissolved copper tank before, and we share it with you here.

In the case of the radar level meter measuring the dissolved copper tank that we are talking about today, there was inaccurate measurement and level fluctuation during the measurement. There are several reasons for this problem.

Firstly, the installation position of the radar level meter is too close to the inner wall of the tank. Due to the proximity to the inner wall of the tank, the radar waves emitted by the antenna hit the inner wall of the tank and are emitted, causing a false liquid level.

The second is the interference from the liquid reflux below the radar level meter. Due to the process itself, in addition to the addition of concentrated sulfuric acid and pure water, there is also reflux from the high-level tank of copper dissolution tank and the high-level tank of roughing and curing.

These reflux liquids are located below or vertically below the radar level meter and affect the level meter measurement. Then the antenna of the radar level meter selected is an insulated rod antenna, the rod antenna has a large emission angle, small measuring range, and weak anti-interference ability, which is not suitable, and the process of dissolving copper produces a lot of steam and acid mist when adding concentrated sulfuric acid, and produces a lot of foam during sandblasting. In the case of weak anti-interference ability of the rod antenna, it also has some influence on the liquid level measurement.

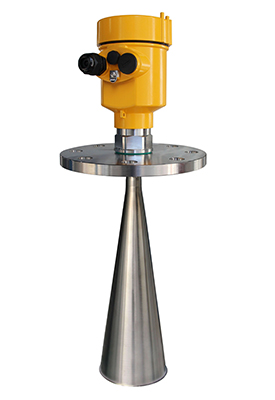

The solution to the above problem is to weld the bypass tube to the outer wall of the molten copper tank on the side of the pumping pump and replace the original plastic threaded interface, and rod antenna radar level meter with a 316L stainless steel flange connected flared antenna radar level meter.

The bypass tube is close to the pumping pump and the purpose of welding is to enhance the circulation of liquid and prevent the liquid in the bypass tube from crystallizing. Foam and acid mist is also significantly reduced in the bypass tube, and the radar level meter installed in the bypass tube still works properly even when the copper raw material is added to the molten copper tube.

Moreover, after changing to flared antenna radar level meter, the emission angle is smaller, and compared with a rod antenna radar level meter, the energy is more concentrated, and the anti-interference ability is stronger, so it can adapt to a more complicated environment.

In this case, we can see the complex environment with the continuous production process, will produce many tricky new problems, the original use of rod antenna radar level meter does not adapt to the site needs, then it is necessary to replace the radar level meter with a different antenna type according to the site situation in a timely manner.

This situation is very common in the radar level meter field measurement, we need to observe in time, analyze the site situation, request the professional help of the manufacturer to change, and debug in order to solve the problem so that we can better complete the measurement task and provide an important guarantee for safe production.