Introduction

Accurate gas flow measurement is essential in various scientific, industrial, and metrological applications. Among the different types of gas flow standard devices, the bell jar gas flow standard device is widely recognized for its high precision and stability. This article explores the working principles, structure, applications, advantages, and limitations of the bell jar gas flow standard device.

Working Principle

The bell jar gas flow standard device operates based on volumetric measurement principles, utilizing a sealed chamber (bell jar) that moves vertically in response to gas flow. The fundamental equation governing its operation is:

Q=V/t

where:

Q is the gas flow rate (volume per unit time),

V is the measured volume of gas,

t is the time taken for the volume to be displaced.

The bell jar is typically filled with a gas, and as gas enters or exits, the jar moves upward or downward. By monitoring the displacement and the corresponding time, the gas flow rate is accurately determined.

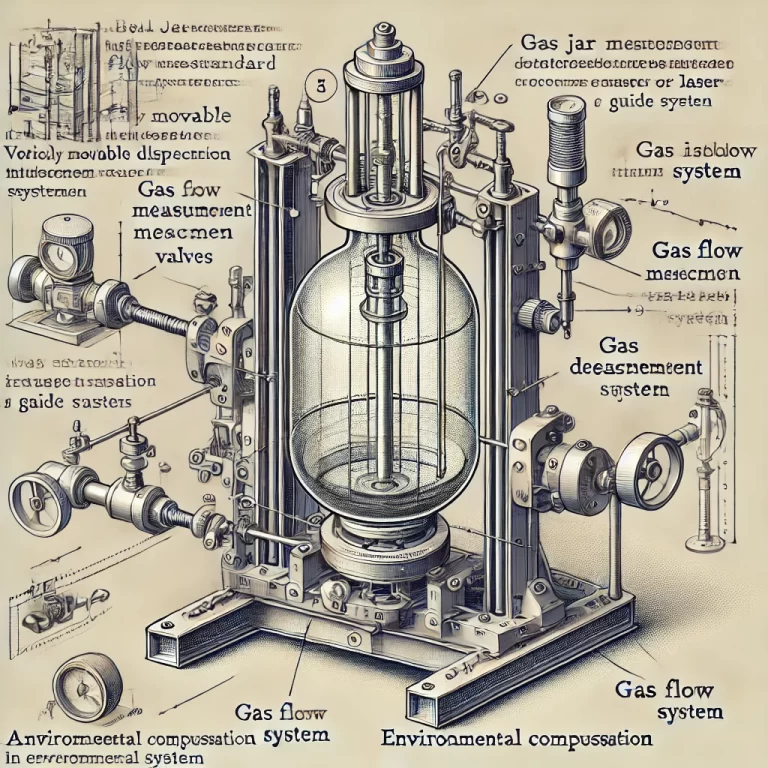

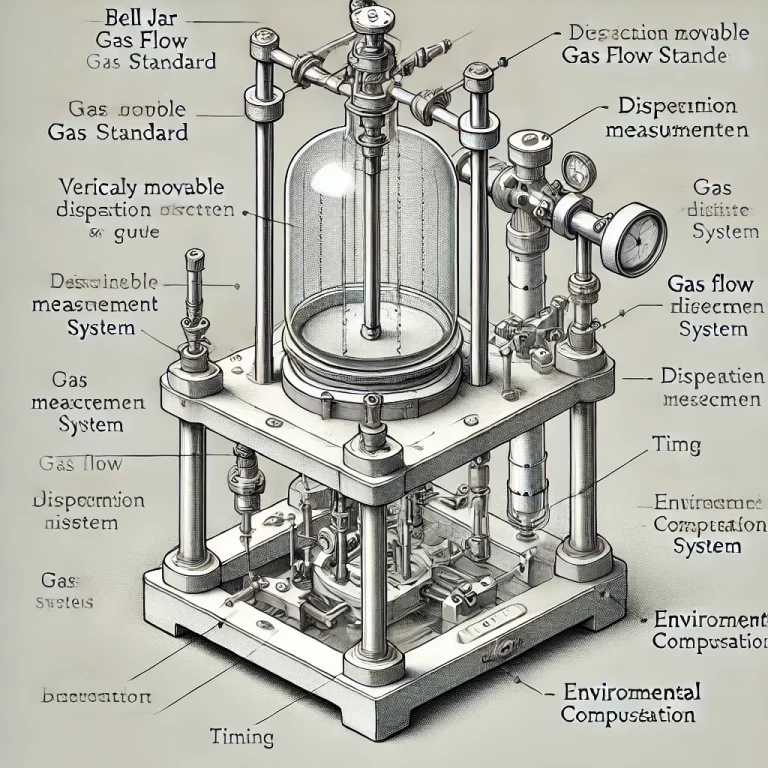

Structure and Components

A typical bell jar gas flow standard device consists of the following components:

Bell Jar: A vertically movable, airtight chamber that expands or contracts as gas flows in or out.

Supporting Frame and Guide System: Ensures smooth, stable movement of the bell jar without tilting.

Displacement Measurement System: Includes high-precision sensors (such as optical or laser displacement sensors) to track the movement of the bell jar.

Gas Inlet and Outlet Valves: Regulate gas entry and exit.

Timing Mechanism: Measures the time interval for volume displacement, often using high-precision electronic timers.

Environmental Compensation System: Adjusts for temperature and pressure variations that may affect measurements.

Operation Procedure

Calibration Preparation: The system is checked for leaks, and environmental conditions such as temperature and pressure are recorded.

Gas Flow Initiation: Gas enters or exits the bell jar, causing it to move.

Displacement Measurement: The volume change is recorded using displacement sensors.

Time Measurement: A timer records the duration of displacement.

Flow Rate Calculation: Using the recorded volume and time, the gas flow rate is computed.

Data Processing and Compensation: Adjustments are made for temperature, pressure, and humidity to ensure measurement accuracy

Applications

The bell jar gas flow standard device is widely used in various fields, including:

Metrology Laboratories: Serving as a primary standard for gas flow calibration.

Gas Flowmeter Calibration: Used for calibrating devices such as thermal mass flow meters, rotameters, and laminar flow meters.

Industrial Gas Measurement: Ensuring accurate flow measurement in gas production, distribution, and quality control processes.

Scientific Research: Used in fluid dynamics studies, gas sampling systems, and environmental monitoring.

Advantages

High Accuracy: Provides highly precise and repeatable measurements due to the stable volumetric principle.

Long-Term Stability: Less affected by external disturbances, making it a reliable reference standard.

Wide Applicability: Can be used for different types of gases, including air, nitrogen, and specialized industrial gases.

Simple Structure: Mechanically straightforward with minimal maintenance requirements.

Direct Volume Measurement: Avoids errors associated with indirect flow measurement methods.

Limitations

| Limitation | Explanation |

|---|---|

| Limited Flow Range | Best suited for low-to-moderate flow rates; not ideal for very high flows. |

| Bulky Design | Requires significant space compared to compact digital flow meters. |

| Manual Operation | Traditional models require human intervention, though modern versions have automation options. |

| Environmental Sensitivity | Temperature and pressure variations require compensation for optimal accuracy. |

Future Trends and Developments

Recent advancements in automation and sensor technology have enhanced the capabilities of bell jar gas flow standard devices. Integration with digital sensors, IoT connectivity, and automated control systems is improving precision, reducing human intervention, and expanding applications in real-time monitoring and remote calibration services.

Conclusion

The bell jar gas flow standard device remains a cornerstone in precision gas flow measurement. Its volumetric accuracy, stability, and reliability make it an indispensable tool in calibration laboratories, industrial applications, and scientific research. While it has limitations in terms of flow range and size, ongoing technological advancements are helping to overcome these challenges, ensuring its continued relevance in the field of metrology and flow measurement.